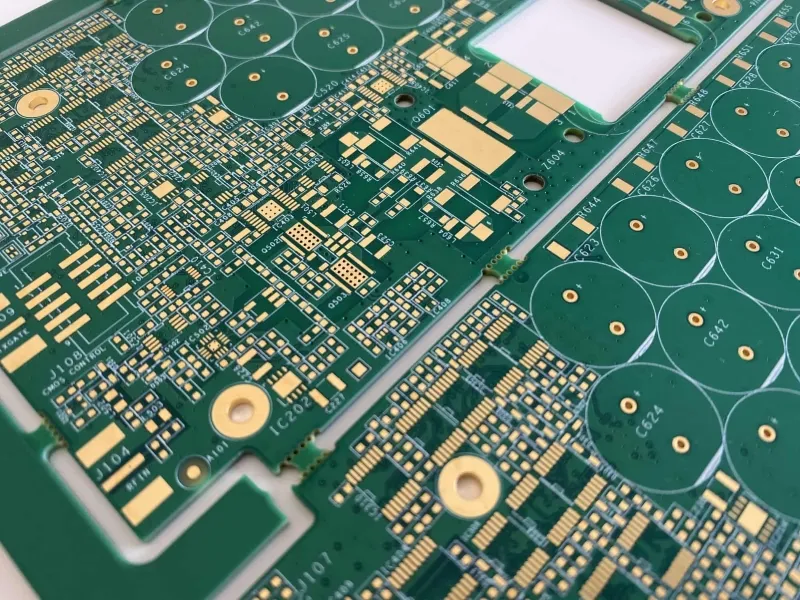

Laser PCB depaneling is increasingly used for low-stress, high-precision applications. However, choosing laser technology does not automatically mean “risk-free.” Based on real production experience, most problems come not from the laser itself, but from overlooked safety details in setup, operation, and process design. This checklist-style article highlights where teams often get it wrong—and how to avoid those pitfalls.

⚠️ Why Safety Is Often Underestimated in Laser Depaneling

Laser depaneling is a non-contact process, so it feels safer than routing or sawing. No blades, no vibration, no mechanical force.

That perception can lead to relaxed standards, especially during early deployment.

Common pain points engineers report include:

- Unexpected fumes affecting nearby processes

- Minor burn marks or discoloration on sensitive boards

- Inconsistent cut quality tied to unsafe parameter settings

Safety in laser depaneling is not only about people—it directly affects product quality and cost.

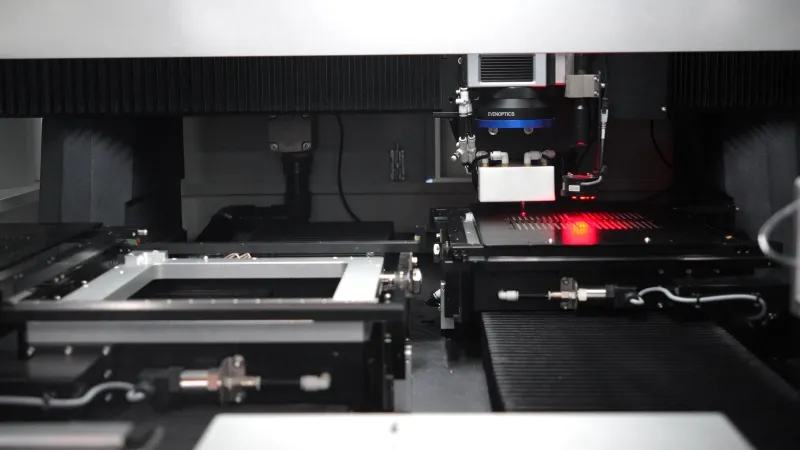

👀 Pitfall 1 – Ignoring Laser Radiation Control

The most basic risk is also the most critical.

- Open or poorly sealed enclosures

- Improper viewing windows

- Inadequate interlock systems

Even Class 1 systems require disciplined enclosure design. Reflected or scattered laser energy may not injure operators immediately, but it can degrade sensors or cameras over time.

Avoidance tip:

Always verify enclosure integrity and interlock logic during commissioning—not just during factory acceptance.

🌫️ Pitfall 2 – Underestimating Fume and Particle Hazards

Laser depaneling vaporizes material instead of cutting it mechanically. This creates:

- Fine particulate matter

- Resin fumes from FR-4

- Potential corrosive residues

Without proper extraction, fumes can contaminate optics, nearby equipment, and even finished boards.

Cost impact:

Neglected fume control often leads to higher maintenance costs and shorter laser lifespan.

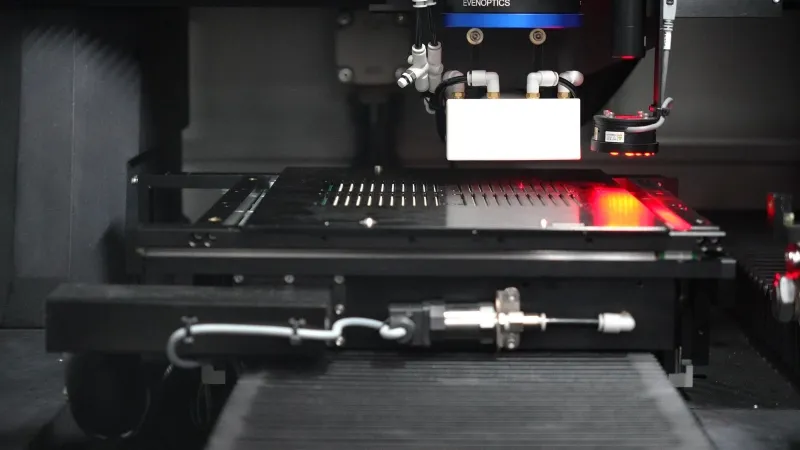

🔥 Pitfall 3 – Thermal Safety vs Mechanical Safety

Laser depaneling eliminates mechanical stress, but thermal management becomes the new risk.

Typical mistakes include:

- Excessive laser power to increase speed

- Insufficient cooling intervals on thin boards

- Overlooking heat-sensitive components near cut lines

While there is no vibration, localized heat can still cause discoloration or micro-damage if not controlled.

📐 Pitfall 4 – Unsafe Parameter Copying

One common shortcut is copying and cutting parameters from another project.

Why is this risky:

- Different PCB materials absorb laser energy differently

- Thickness and copper distribution change the heat behavior

- Coatings and solder mask react unevenly

What worked safely before may not work again.

📊 Pitfall 5 – Poor Process Validation

Laser depaneling often passes visual inspection easily. Clean edges can hide deeper issues.

What teams miss:

- Long-term reliability testing

- Microsection analysis near cut edges

- Electrical stress testing post-depaneling

Skipping validation may reduce upfront cost—but increases downstream risk.

💰 Safety vs Cost – A Practical View

Many safety-related shortcuts are driven by cost pressure:

- Smaller fume extraction systems

- Lower enclosure specifications

- Reduced validation cycles

In reality, safety oversights often increase total cost through:

- Rework

- Yield loss

- Equipment downtime

A safer process is usually the more economical one over time.

🧪 H2: Case Insight from Production

A consumer electronics manufacturer introduced laser depaneling to reduce routing stress. Initial results looked good, but after several weeks, the yield dropped.

Root cause:

- Inadequate fume extraction led to optical contamination

- Cutting consistency degraded gradually

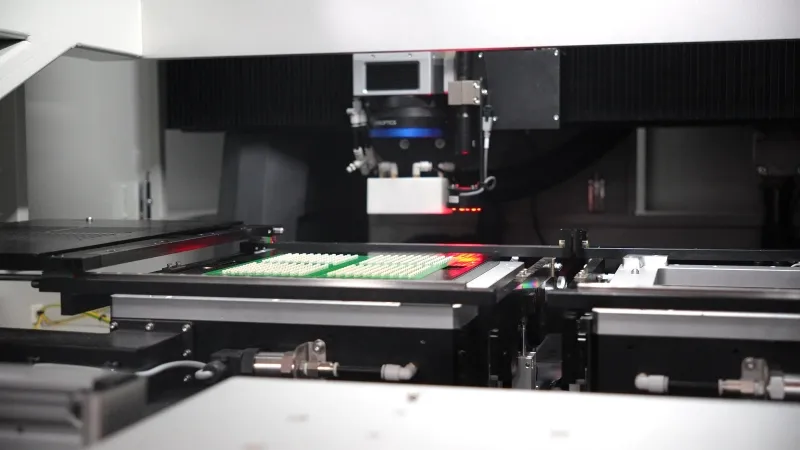

After optimizing the setup using a Seprays laser depaneling system with proper enclosure design and extraction, stability returned, and maintenance intervals doubled. The lesson was clear: safety controls protect both people и process stability.

🛠️ A Practical Safety Checklist (Avoid-the-Pitfalls Edition)

Before running volume production, confirm:

- Fully enclosed laser system with tested interlocks

- Proper fume extraction matched to PCB material

- Verified thermal parameters for each board type

- Clean optics inspection schedule

- Process validation beyond visual checks

Laser depaneling rewards discipline more than shortcuts.

⚡ Seprays Laser Depaneling Advantages

When safety and process stability are considered together, Seprays laser solutions are designed to reduce risk:

- Repeat precision (<2 μm) for controlled energy delivery

- No mechanical stress or vibration

- Ultra-fine kerf (<25 μm) improves material utilization and reduces heat spread

- Free-form cutting without tool pressure

- No consumables, eliminating blade-related hazards

- Clean, residue-free cuts with proper extraction

- Fast and stable operation for inline environments

These advantages help transform safety from a concern into a process strength.

⭐ Why Choose Seprays Group?

Seprays Group approaches laser depaneling as a manufacturing system, not just a cutting tool. Our focus is on safe, stable, and repeatable results in real production environments.

If you are reviewing safety risks or planning a laser depaneling project, contact us for a technical discussion or sample evaluation.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)