Specifications

| Нет. | Технический параметр | ZAM330 |

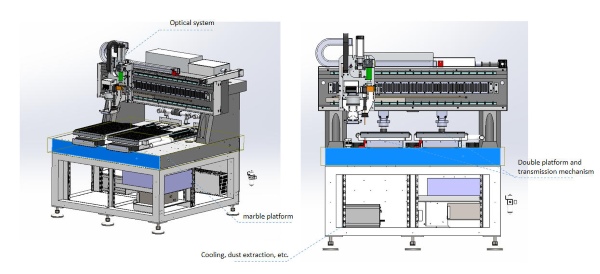

| 1 | Platform Type | Dual platform |

| 2 | Processing Range | 350 × 500 mm × 2 pieces |

| 3 | Точность повторения | ±2 μm |

| 4 | Overall Accuracy | ±20 μm |

| 5 | X/Y Resolution | X/Y = 1 μm |

| 6 | Max. Material Thickness | ≤2.0 mm |

| 7 | Platform Structure | Гранитная платформа |

| 8 | Motor Type | Линейный двигатель |

| 9 | Laser Type | Nanosecond |

| 10 | Laser Power | 15W, other options available |

| 11 | Focus Spot Diameter | 20 μm ±5 μm |

| 12 | Adjustable Beam Expander | Optional |

| 13 | High-speed Galvo | Germany Scanlab |

| 14 | Focal Length of Telecentric Lens | 50 × 50 mm, f = 100 mm |

| 15 | CCD Structure | Paracentric |

| 16 | Positioning Accuracy | 0.01 mm |

| 17 | Camera Resolution | 1.3 MP / optional 5 MP |

| 18 | Camera Light Source | Standard red ring light |

| 19 | Pulse Auto-follow | Femtosecond / Picosecond standard |

| 20 | Galvo Pre-acceleration | Yes |

| 21 | Advanced Drilling Function | Optional |

| 22 | Защита безопасности | Yes |

| 23 | Пылеуловитель | Industrial vacuum |

| 24 | Cooling Method | Built-in water cooling |

| 25 | UPS Power Supply | Optional for the computer |

| 26 | Voltage Stabilizer | External, optional 7.5 kW or 15 kW |

| 27 | Display | 17-inch |

| 28 | Control Software | Создатель мечты 3 |

| 29 | Программное обеспечение для обработки данных | Circuit CAM7.5 Standard |

| 30 | File Formats | LMD, standard Gerber (RS-274-D), extended Gerber (RS-274-X), DXF, Excellon, Sieb & Meier, HP-GL, Barco DPF, ODB++ |

| 31 | Operating Environment | 22°C ±2°C |

| 32 | Источник питания | 380 VAC / 50 Hz / 3.5 kW |

| 33 | Вес | Approx. 2000 kg |

| 34 | Dimensions (W × H × D) | 1600 × 1750 × 1600 mm |

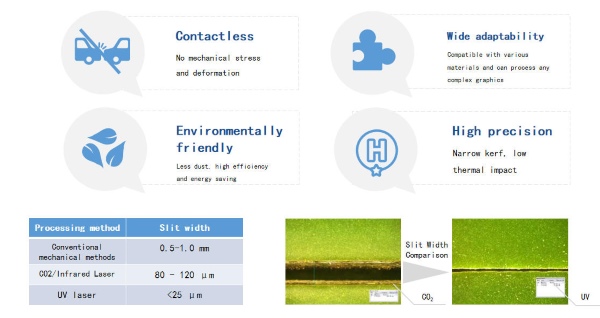

В ZAM330/330D Offline Precision Laser Depaneling Machine is designed for high-precision, non-contact depaneling of a wide range of materials, including FPC, PCBA, and ceramics. Ideal for industries like semiconductor, telecommunications, lighting, and more, this machine ensures clean, burr-free cuts with laser precision.

🔥 Key Features

-

Dual-Platform Design: Reduces material loading and unloading time, keeping the laser in continuous operation for improved efficiency.

-

Large Working Area: Processes 350mm × 520mm panels, ideal for post-SMT depaneling, coverlay cutting, and more.

-

High-Precision Laser: With advanced laser control, it achieves micron-level precision for cutting and shaping.

-

Non-Contact Processing: The laser sublimates the material without physical contact, eliminating stress and distortion.

-

Automatic Data-Driven Production: Direct input from product data to instantly begin processing, saving time and improving workflow efficiency.

💡 Advanced Technology

Engineers equipped the ZAM330/330D with a high-precision laser cutting system, designed to deliver optimal results even in the most complex paths. With advanced software integration, users benefit from powerful tools for editing, data processing, and system control. The machine also supports integration with MES systems, enabling seamless tracking, reporting, and data management.

⚙️ Versatile Applications

Perfect for a range of materials, including:

-

FPC

-

LCP

-

MPI

-

PI

-

FR4, FR5, and CEM

-

Polyester materials

-

Ceramics and RF materials

🌍 Industrial-Grade Reliability

The ZAM330/330D is designed for large-scale production, ensuring consistency и high throughput for mass manufacturing needs. Its marble base provides stability, and the advanced dust and cooling systems keep the machine running smoothly during continuous operations.

⚡ Laser software applications

Unique machining paths significantly improve machining results.

Specially optimized operation paths enhance machining efficiency.

Powerful graphics editing capabilities enable intuitive, convenient, and fast data processing.

A handful of completely independent kernels

Graphical human-computer interaction (GUI)

Intuitive and smooth, low learning curve

📈 Control & Process

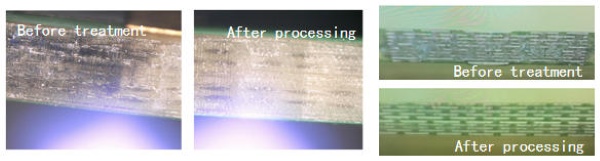

Pulse Following: By controlling pulse synchronization, it ensures uniformity in line and energy, ensuring carbonization-free processing and achieving superior results.

Ultra-Clean Cutting: Perfectly integrated with the cutting process, fully automated operation, and flexible configuration deliver the perfect balance of speed, accuracy, and results.

High-Precision Laser Cutting System – Control and Process

Combined with Genmo’s independently developed software and hardware, it adapts to the mobile system from the ground up, meeting precision, speed, and complex path requirements.

Through close collaboration with the laser, advanced features such as Pulse Following and Skywriting are available as options.

💡 Laser Cutting Case

В ZAM330/330D Offline Precision Laser Depaneling Machine is your ideal choice for accurate, high-speed depaneling, with minimal manual intervention. It’s an essential tool for enhancing production efficiency and ensuring superior product quality in high-tech industries.

Свяжитесь с Нами для получения цен и подробной информации

Свяжитесь с Нами для получения цен и подробной информации

Электронная почта: sales@seprays.com

WhatsApp: +86-189 2926 6433

.png)

评价

目前还没有评价