The comparison between Automatic PCB Router Machines и V-Cut Systems is a topic frequently discussed among global SMT engineers, especially as PCB designs become thinner, denser, and more reliability-driven. While both technologies remain widely used, real production experience shows that the choice is rarely about speed alone—it is about long-term process stability, stress control, and total cost of ownership.

🧱 Mechanical Impact — Stress Is the First Decision Point

From an engineering perspective, the core difference lies in how each method applies force to the PCB.

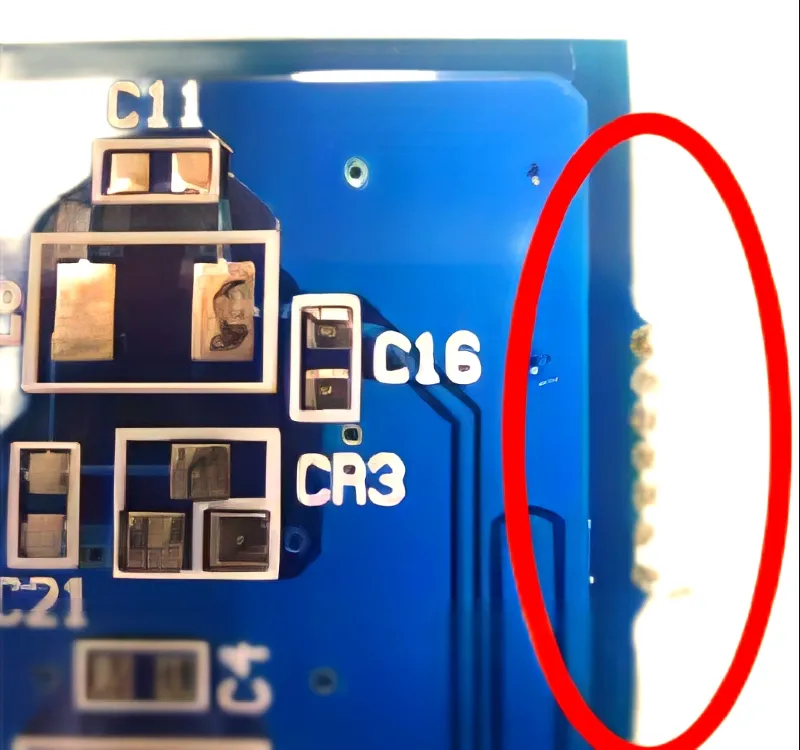

V-cut systems rely on mechanical separation along predefined grooves. While efficient, this approach introduces bending stress that can affect:

- Ceramic capacitors near the cut line

- Fine-pitch solder joints

- Thin or uneven panel designs

Router-based systems remove material progressively, which significantly reduces mechanical stress. Many SMT lines report fewer latent defects when routing is used for high-density or sensitive assemblies.

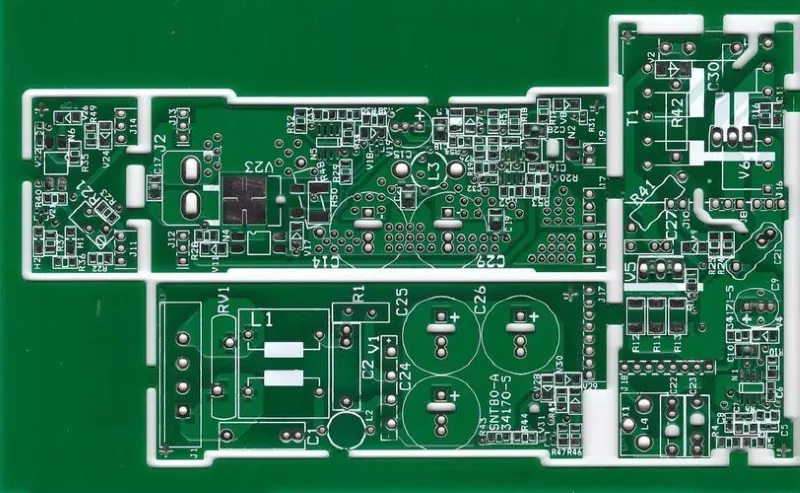

🎯 Accuracy and Design Flexibility

One recurring pain point shared by production teams is the frequency of design changes.

V-cut advantages:

- Simple straight-line separation

- Lower initial equipment cost

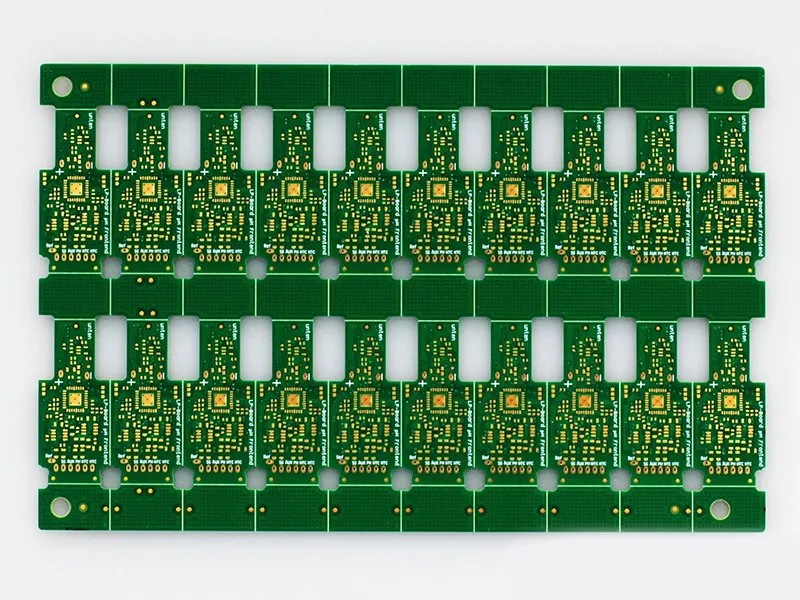

- Fast cycle times for uniform panels

However, limitations appear when:

- Board outlines become irregular

- Components are placed close to the edges

- Multiple board designs share one panel

Automatic routing systems offer greater flexibility, supporting complex geometries and tighter tolerances, which align better with modern PCB layouts.

⚙️ Durability and Long-Term Stability

In continuous SMT environments, equipment durability often matters more than peak throughput.

Engineers frequently mention:

- Blade wear and alignment drift in V-cut systems

- Increased maintenance when processing thicker panels

- Variability between operators

Router machines, when built with rigid frames and industrial-grade spindles, tend to maintain accuracy over longer operating periods, reducing recalibration and unplanned downtime.

📉 Cost Analysis — Beyond the Purchase Price

While V-cut equipment usually requires lower upfront investment, several factories report hidden costs over time:

- Scrap caused by micro-cracks

- Reliability failures discovered during aging tests

- Increased inspection workload

Routing systems often involve a higher initial cost but help reduce yield loss and quality-related rework, particularly in automotive, medical, and industrial electronics.

🌍 Global SMT Case Observations

- Europe: Preference for routing in automotive and industrial electronics due to reliability standards

- North America: Mixed usage, with routing favored for complex, high-value boards

- Asia: V-cut still common in high-volume consumer products, routing growing in advanced applications

The decision often reflects product life cycle expectations rather than regional habits.

🧩 Choosing the Right Approach

Experienced engineers suggest evaluating:

- PCB thickness and material

- Component proximity to edges

- Reliability requirements

- Design change frequency

- Expected production volume

No single method fits all applications, but understanding stress behavior and durability helps avoid costly long-term issues.

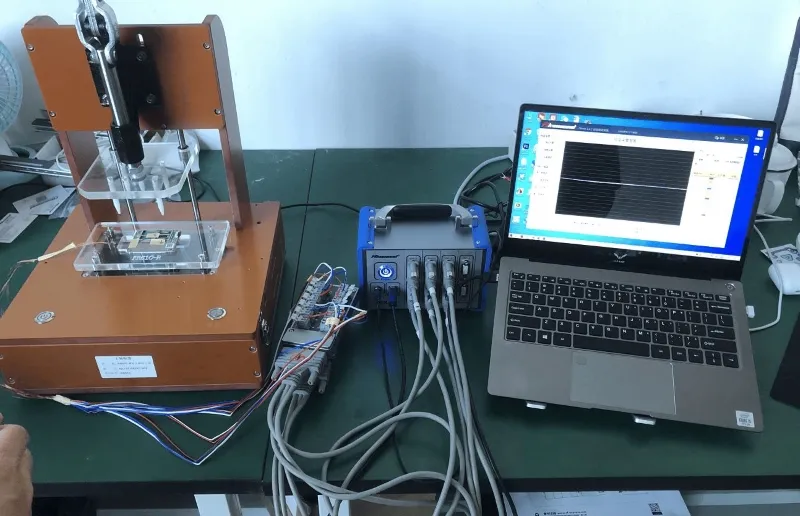

Why Choose Seprays Group?

Seprays Group develops industrial-grade depaneling solutions focused on mechanical stability, controlled stress, and long-term reliability. Our experience across global SMT lines allows us to support both routing and V-cut applications based on real production needs—not assumptions.

If you would like to discuss your specific PCB depaneling challenges, please contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)