German SMT production environments are known for their strict expectations on precision, durability, and process repeatability. When evaluating a PCB depaneling system, engineers focus not only on cutting performance but also on long-term stability, integration capability, and predictable cost of ownership. This article summarizes the practical criteria observed in German automotive, industrial control, and medical electronics workshops.

🔧 Router Solutions — Mechanical Stability and Tool Management

Router-type depaneling remains common in high-mix SMT lines. German engineers frequently emphasize spindle rigidity, vibration control, and tool wear consistency. A stable Z-axis design helps maintain predictable kerf width, which is essential for dense PCBA layouts.

Common pain points include:

- Variations in tool diameter after prolonged operation

- Dust extraction efficiency for FR4 and aluminum substrates

- Difficulty keeping ±0.05 mm accuracy during long shifts

In many German factories, tool-life monitoring combined with fiducial-based correction is used to control long-term dimensional drift. It reduces scrap risk and prevents unexpected downtime.

⚡ Laser Cutting — Precision, Edge Quality, and Cleanliness

Laser depaneling has gained adoption where reliability requirements are high. Engineers in Germany often highlight two evaluation points:

- Heat-affected zone behavior,

- repeatability under continuous 24/7 operation.

A well-designed laser system should provide:

- Minimal thermal impact for RF modules and flexible substrates

- Burr-free edges that improve downstream coating or testing

- Narrow kerf for compact designs

The long-term cost challenge is usually the laser source lifetime and maintenance intervals. Several automotive plants share that stable micron-level cuts significantly reduce rework, despite higher initial investment.

✂️ V-Cut Solutions — Durability and Cost Efficiency

V-cut scoring remains cost-effective for standard boards. German SMT lines tend to evaluate scoring angle consistency, blade hardness, and chassis stiffness rather than speed alone.

Practical challenges:

- Board stress when components are placed near the score line

- Variation in score depth affects break force

- Long-term wear of blades increases the risk of cracked PCBs

Well-maintained V-cut systems are still reliable for consumer and industrial electronics, but they require disciplined preventive maintenance to ensure uniform results.

🪚 Saw Blade Systems — Where They Fit in German Production

Saw blade depaneling is used when thick materials or metal-core PCBs are involved. German workshops often examine:

- Blade alignment accuracy

- Edge chipping on aluminum substrates

- Acoustic noise levels in clean production environments

The machine’s main advantage lies in its robustness for heavy boards, although operators rarely use it for fine-pitch assemblies.

📊 Cost Analysis in German SMT Facilities

Several factories report that the real cost difference between depaneling methods comes from quality losses and downtime, rather than equipment price. Key factors include:

- Scrap caused by stress or thermal distortion

- Time spent on tool replacement or alignment

- Integration with MES and production tracking

- Maintenance intervals affecting line uptime

A system that maintains stability over months—not days—usually produces better long-term ROI.

🏭 Case Observations from German Workshops

- Automotive Electronics: Laser is preferred for sensitive components and complex outlines.

- Industrial Modules: Router systems dominate due to flexibility and predictable wear behavior.

- Power Electronics: Saw blades are applied for thick PCBs requiring strong mechanical separation.

- Consumer Devices: V-cut solutions remain cost-effective when board design allows.

These observations highlight that no single method is universally best—matching the process to the product and quality tolerance is the key.

🧩 Practical Selection Framework

Engineers in Germany often use a decision matrix involving:

- required precision

- material and board thickness

- stress tolerance

- expected long-term stability

- maintenance availability

- integration with existing SMT lines

A structured evaluation helps avoid over-specification or under-investment.

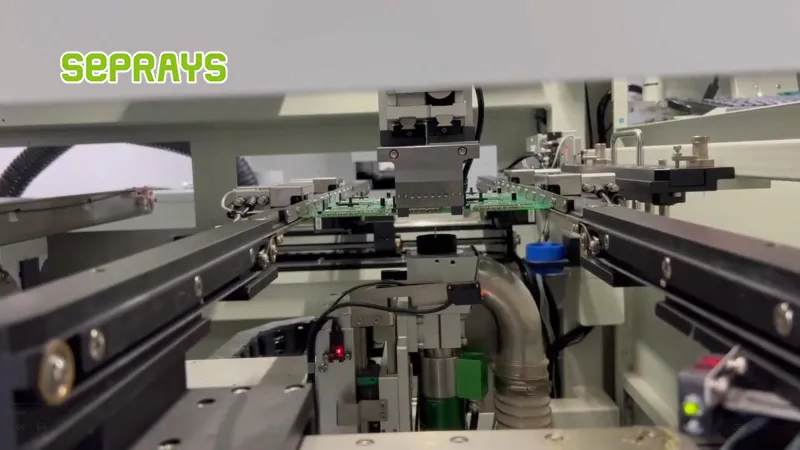

Why Choose Seprays Group?

Seprays Group focuses on precision, long-term durability, and stable industrial performance—qualities valued in German SMT environments. Our solutions support router, laser, V-cut, and saw-blade configurations, ensuring that engineers can select equipment based on technical needs rather than a single method.

If you would like more details or sample test results, please contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)