Laser depaneling machine technology is rapidly transforming how electronics manufacturers handle printed circuit board assemblies (PCBAs). If you’re seeking more precision, less mechanical stress, and higher throughput, this non-contact solution could be exactly what your production line needs.

But is it the best fit for your process?

Let’s explore the benefits, ideal applications, and key considerations.

⚙️ What Is a Laser Depaneling Machine?

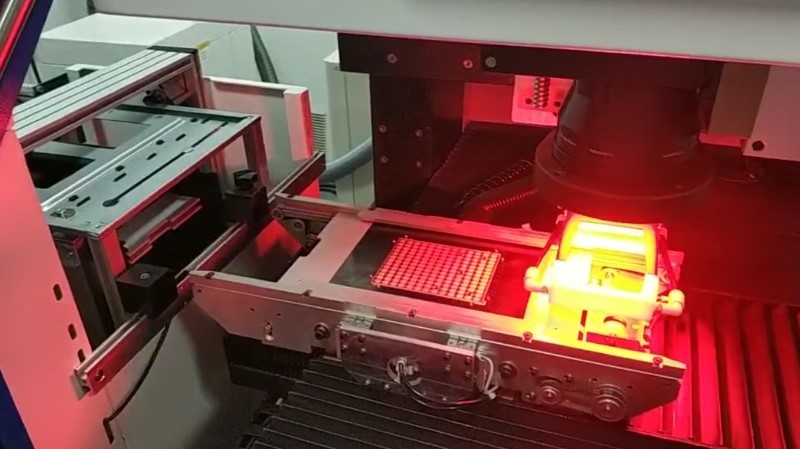

A laser depaneling machine uses high-energy laser beams to separate PCBs from a panel without physical contact. Unlike traditional routing or punching, there’s no tool wear, vibration, or dust.

It works with various materials, including FR4, polyimide, ceramics, and even flexible substrates. Ideal for high-density or miniaturized boards, it delivers ultra-clean edges with micrometer-level precision.

🚀 Advantages Over Traditional Depaneling

- Zero mechanical stress

No pressure applied = no risk of cracks or microfractures. - Cleaner cuts

No burrs or debris. Perfect for medical, aerospace, and high-reliability electronics. - Flexible geometry

Curved or irregular outlines? No problem with laser precision. - Low maintenance

No bits or blades to replace. Less downtime.

🔧 Is Laser Depaneling Right for Your PCBA?

It depends on your product and volume. This solution is best for:

- Thin or flexible PCB designs

- High-volume production lines

- Boards with complex or tight layouts

- Industries needing tight tolerance and no contamination (e.g., automotive, medical)

However, initial investment is higher than traditional routers or V-cut systems. But over time, savings in maintenance and rework may outweigh the upfront cost.

🧪 Factors to Consider Before Investing

- Material type – Not all PCB materials respond the same to laser.

- Cutting speed vs. accuracy – You may need to balance speed with fine tolerances.

- Board thickness – Best suited for thin or semi-rigid boards (<1.6mm).

- System integration – Check if it fits into your current automation flow.

🤖 Future-Proofing Your PCBA Line

As electronics trend smaller and more complex, laser depaneling machines offer a scalable solution. They support automation, reduce labor, and enable greater design freedom, making them ideal for forward-thinking manufacturers.

💡 Why Choose Seprays Group?

At Seprays Group, we specialize in intelligent depaneling solutions tailored to your unique production needs. Our laser depaneling systems are:

- Precision-engineered for complex boards

- Backed by technical support worldwide

- Customizable for both inline and offline operations

✅ Need help choosing the right machine?

Contact us today — we’re here to support your journey to smarter PCB manufacturing.

.png)