Новости

Автоматическая Фрезерная машина для печатных плат GAM 300AT – Опора Подается назад для непрерывной работы

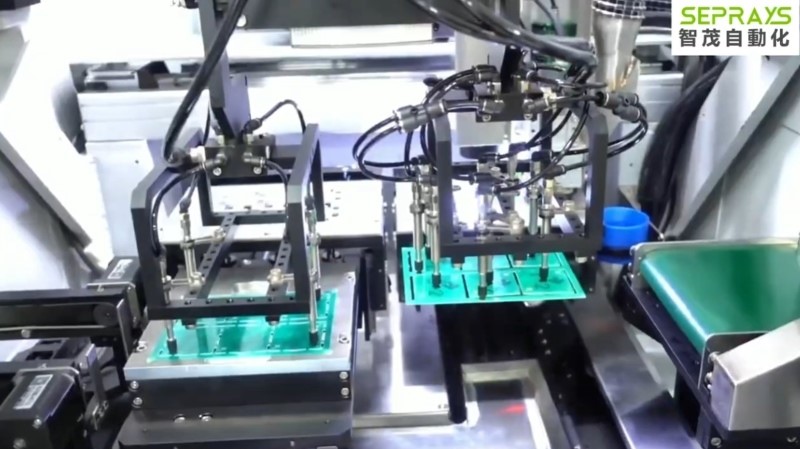

The GAM 300AT Automatic PCB Router Machine is built for modern SMT production lines that rely on carriers for every stage of manufacturing. Designed for continuous operation, it delivers precision routing without interruptions. If your line handles board edge-free designs, power adapters, or compact PCBs, this machine is an ideal fit. 🏭 Engineered for Carrier-Based Production The GAM 300AT Automatic PCB Router Machine is optimized for environments where carriers transport boards through each process. This setup: By keeping carriers in motion — even after depaneling — production can run smoothly without bottlenecks. 🎯 High-Precision Cutting with CCD Vision Accuracy is everything in PCB manufacturing. The GAM 300AT features a high-speed CCD vision alignment system. It detects any offset, then automatically adjusts the cutting path for perfect results. This means: ⚡ ESD Protection with Smart Tool Change Sensitive PCBAs can be damaged by static. That’s why this router uses a high-speed ESD-protected spindle. It also comes with automatic tool-change, which: You get both efficiency and safety in one package. 🧩 Compact Design for Easy Integration Space is often tight in SMT lines. The GAM 300AT is compact, making it easy to integrate into existing layouts. It’s perfect for: 🛠️ Optional Upgrades

Следите за чистотой ваших SMT-трафаретов в любом месте с помощью нашего портативного средства для чистки трафаретов

Blocked stencil holes are a common cause of poor solder printing in SMT production. That’s where the Portable Stencil Cleaner steps in — the smart solution for high-precision electronics assembly. Whether you’re working with fine-pitch stencils or dealing with frequent paste residue, this tool ensures your production remains efficient and defect-free. ⚙️ What Is a Portable Stencil Cleaner? A Portable Stencil Cleaner is a compact device used to clean solder paste stencils during or between printing cycles. It removes paste residues from fine holes without damaging the stencil. This tool is vital for: 🔊 Ultrasonic Vibration for Deep Cleaning The GAM 40 Portable Stencil Cleaner uses ultrasonic vibration to clean the inner hole walls of SMT steel plates. This technology: It enhances the SMT process by ensuring precise paste deposition, especially for fine-pitch components. 🧩 Compact and Lightweight Design Designed with a lightweight body, the GAM 40 is: No complex setup or training required. Just plug, clean, and go. 💡 Designed for Online Cleaning What sets the GAM 40 apart? ✅ Instant online stencil cleaning during the solder printing process✅ No need to stop production✅ Maintains consistent aperture cleanliness✅ Prevents solder bridges and voids✅ Keeps yields high and rework low

Автоматический станок для фрезерования дна печатных плат – Идеально подходит для подрезки плат с высоким содержанием компонентов

When working with tall components or sensitive boards, standard depaneling tools won’t do. An Automatic PCB Bottom Router Machine is the ideal solution for undercutting and handling complex PCBAs with top-side components up to 70mm tall. Let’s explore how this machine transforms precision routing for demanding PCBA designs. 🏗️ Built for Tall-Component Boards The Automatic PCB Bottom Router Machine stands out due to its unique undercutting design. Unlike top routing machines, this model cuts from below, allowing clearance for high components on the top side of the board. This reduces the risk of collisions and improves yield in: It’s your go-to solution for routing tall, delicate assemblies with maximum safety and accuracy. 🎯 Vision-Guided Accuracy with CCD System Accuracy starts with positioning. The GAM386AT is equipped with an advanced CCD visual positioning system. This ensures perfect alignment and offset correction before each cut. The result? Ultra-precise routing — even on densely packed or irregular PCBs. ⚡ ESD Protection & Auto Tool Change Sensitive electronics require anti-static handling. That’s why this Automatic PCB Bottom Router Machine includes a high-speed spindle with ESD protection. It also features automatic tool changing, which: Together, these features ensure high reliability for mission-critical applications. 🌬️ Built-In

Выберите подходящий станок для снятия панелей с печатных плат V-образного сечения в соответствии с Вашими производственными потребностями

Selecting the right V-Cut PCB Depaneling Machine is essential for maintaining production efficiency and board quality. Whether you’re producing LED strips, aluminum substrate boards, or standard PCBs with V-grooves, a reliable V-Cut separator helps prevent damage and boosts productivity. Here’s how to choose the best-fit model for your production line. 🛠️ What Is a V-Cut PCB Depaneling Machine? A V-Cut PCB Depaneling Machine is used to separate multiple printed circuit boards that have been pre-scored with V-grooves. It ensures clean, straight cuts without damaging the components or solder joints. This machine is commonly used in: ⚙️ Introducing the SEPRAYS ZM30 The ZM30 V-Cut PCB Depaneling Machine is engineered by SEPRAYS for high-speed, low-stress depaneling. It is ideal for separating: This machine reduces the stress applied during cutting, minimizing the risk of cracked solder joints or damaged components. 🚀 Key Features of the ZM30 V-Cut Separator 🔧 Why It’s Ideal for Mass Production The V-Cut PCB Depaneling Machine allows for batch processing at high speed with minimal maintenance. Its precision makes it ideal for: Its automatic, stress-free cutting approach extends PCBA lifespan and boosts customer satisfaction. 💼 Used by Global Electronics Giants The ZM30 is already in use by Fortune 500

Изучите лучший автоматический фрезерный станок для печатных плат для массового производства

Looking for the best Automatic PCB Router Machine to level up your production line? If you’re in high-volume PCB manufacturing, precision, efficiency, and reliability are non-negotiable. That’s where an Automatic PCB Router Machine comes in. It streamlines your depaneling process with high-speed, accurate routing — all while minimizing stress on your boards. Let’s explore how this solution can reshape your PCBA operations. ⚙️ What Is an Automatic PCB Router Machine? An Automatic PCB Router Machine is a fully automated depaneling system designed to cut individual circuit boards from a large panel. Unlike manual or semi-automatic methods, this machine performs the entire process — loading, cutting, and unloading — with minimal human intervention. It’s a must-have for factories looking to scale production while maintaining tight tolerances. 🚀 Why Choose a Router Over Traditional Methods? 🔧 Meet the GAM 330AT: Built for High Efficiency The GAM 330AT Automatic PCB Router Machine by SEPRAYS is designed for smart factories. 🛠️ Optional Add-Ons for Custom Production Enhance your router’s capabilities with: These options support diverse process flows and tighter traceability. 📦 Dual-Spindle Options Available Need even more power? The GAM330AT series includes dual-spindle models like: These boost throughput while maintaining Seprays’ signature precision and

Подходит ли лазерная машина для снятия панелей для вашего процесса PCBA?

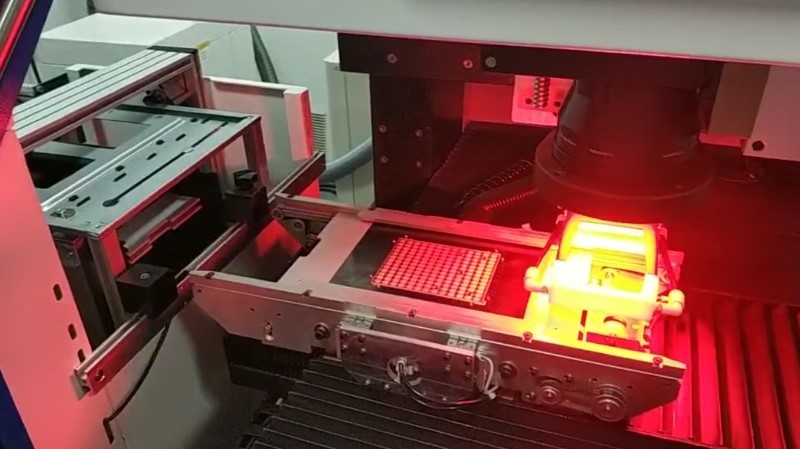

Laser depaneling machine technology is rapidly transforming how electronics manufacturers handle printed circuit board assemblies (PCBAs). If you’re seeking more precision, less mechanical stress, and higher throughput, this non-contact solution could be exactly what your production line needs. But is it the best fit for your process? Let’s explore the benefits, ideal applications, and key considerations. ⚙️ What Is a Laser Depaneling Machine? A laser depaneling machine uses high-energy laser beams to separate PCBs from a panel without physical contact. Unlike traditional routing or punching, there’s no tool wear, vibration, or dust. It works with various materials, including FR4, polyimide, ceramics, and even flexible substrates. Ideal for high-density or miniaturized boards, it delivers ultra-clean edges with micrometer-level precision. 🚀 Advantages Over Traditional Depaneling 🔧 Is Laser Depaneling Right for Your PCBA? It depends on your product and volume. This solution is best for: However, initial investment is higher than traditional routers or V-cut systems. But over time, savings in maintenance and rework may outweigh the upfront cost. 🧪 Factors to Consider Before Investing 🤖 Future-Proofing Your PCBA Line As electronics trend smaller and more complex, laser depaneling machines offer a scalable solution. They support automation, reduce labor, and enable greater

.png)