PCB Milling Cutter Machine technology has increasingly replaced traditional V-cut separation in global SMT factories, especially as PCBs become thinner, denser, and more mechanically sensitive. While the V-cut method remains widely used in cost-driven or legacy production lines, manufacturing teams in Europe, North America, and Southeast Asia are reconsidering which depaneling approach brings better stability, reliability, and long-term yield.

Below is a practical comparison based on insights shared by engineers, maintenance technicians, and line supervisors from Germany, France, the United States, and key Asian manufacturing hubs.

🏭 H1 — Why Factories Reevaluate PCB Separation Methods

The core issue for modern SMT lines is mechanical stress.

- Components are becoming smaller and more fragile.

- PCB thickness is trending downward (0.6–1.0 mm).

- Assemblies contain more tall connectors near the panel edges.

- Automotive and industrial electronics demand higher reliability.

V-cut’s simplicity is appealing, but it introduces bending forces that many OEMs now consider unacceptable. Milling cutters, in contrast, reduce stress significantly but bring higher equipment and tool costs.

Manufacturers are now weighing precision, durability, and long-term reliability over pure cycle time.

🔧 H2 — Pain Points: What Engineers Report from Daily Production

V-Cut Common Pain Points

- High bending stress causes micro-cracks in MLCCs

- Inconsistent groove depth from suppliers

- Sharp edges requiring secondary deburring

- Deformed PCBs after separation

- Limited suitability for high-density layouts

PCB Milling Cutter Machine Pain Points

- Tool wear leading to burrs if unmanaged

- Higher initial investment

- Need for dust collection to maintain quality

- Slightly longer cycle time depending on the outing path

Teams across Germany and France emphasize that defect predictability matters. V-cut-related failures often appear months later in the field, increasing warranty burden.

⚙️ H3 — Cost Analysis: Short-Term Savings vs Long-Term Reliability

Factories usually classify costs into two categories:

1. Direct Costs (visible)

- V-cut scoring cost from PCB supplier

- Milling cutter (router bit) consumption

- Machine investment and maintenance

- Cycle time and energy consumption

2. Indirect Costs (hidden but critical)

- Component cracking (especially ceramics)

- Rework and scrap rate

- Warranty claims from latent reliability failures

- PCB deformation affecting downstream assembly

A German EMS manufacturer shared that switching to milling reduced MLCC cracking by over 70%, saving tens of thousands of euros per year in rework.

Thus, the choice is rarely about price — it’s about total lifecycle cost.

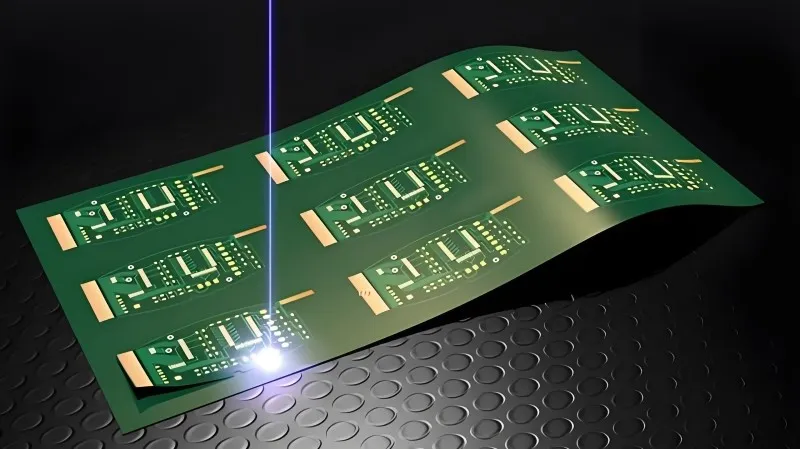

📘 H4 — Real-World Case Study: Industrial Control Products in France

A French industrial electronics producer faced repeated failures during ICT due to hairline cracks in capacitors caused by V-cut bending. Their conditions:

- 1.0 mm FR-4

- Fragile ceramic components near the panel edge

- Moderate annual volume (500k units/year)

After transitioning to a PCB milling cutter machine:

- The component failure rate dropped dramatically

- Panel flatness improved

- No extra deburring needed

- Changeover flexibility increased for small batch runs

Their engineers concluded that routing significantly improved long-term product reliability and better matched modern PCB design trends.

🛠️ H5 — Technical Comparison: What SMT Lines Prefer Today

1. Precision

- Milling: ±0.05 mm accuracy

- V-cut: limited by groove quality and blade sharpness

2. Stress

- Milling: very low mechanical stress (ideal for sensitive components)

- V-cut: high bending stress

3. Design Flexibility

- Milling: supports curves, complex shapes, and uneven panel designs

- V-cut: only straight lines

4. Maintenance

- Milling: requires monitoring of tool wear

- V-cut: needs periodic blade replacement

5. Long-Term Yield

- Milling: higher for dense and fragile boards

- V-cut: acceptable for robust, low-cost designs

The preference varies by region:

- Germany and France strongly favor milling for reliability.

- The U.S. market is increasingly transitioning due to mixed product lines.

- Southeast Asia still uses V-cut for large-volume, cost-driven programs.

🧩 H6 — Discussion: When to Choose Which Method?

Choose PCB Milling Cutter Machine when:

- Components sit <2 mm from board edges

- PCBs are thin (0.6–1.0 mm)

- Complex shapes or precise tolerances are required

- Long-term reliability matters (automotive, industrial, aerospace)

- Minimizing vibration and stress is critical

Choose V-Cut when:

- The product is mechanically robust

- Volume is extremely high, and cost sensitivity is severe

- Panel design is simple and predictable

- Minor edge roughness is acceptable

Most global SMT lines now adopt a hybrid strategy — using milling for sensitive boards and V-cut for robust, high-output consumer products.

⭐ Why Choose Seprays Group?

Seprays Group specializes in high-precision PCB depaneling systems built for manufacturers prioritizing reliability, stability, and long-term cost efficiency. Our solutions support complex panel designs, fragile components, and zero-stress separation requirements across global markets.

If you need technical guidance, application analysis, or equipment recommendations, please contact us anytime.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)