Router depaneling vs V-cut is one of the most practical decisions PCB engineers face when balancing cost, quality, and long-term reliability. The short answer is simple: choose router depaneling when mechanical stress, design flexibility, and edge quality matter more than raw speed. Below, we break this down from real production experience—not theory.

🔍 What problem are engineers really trying to solve?

Most depaneling issues don’t show up at the cutting stage. They appear later as:

- Cracked MLCCs after functional testing

- Intermittent failures during aging

- Lower yield in high-density PCBA

- Customer complaints months after shipment

The depaneling method often becomes the hidden root cause.

⚙️ When V-cut starts to struggle

⚠️ High mechanical stress

V-cut relies on the bending force to separate boards. This force travels through the entire PCB, not just the score line. For simple, low-density boards, this may be acceptable. For sensitive designs, it’s risky.

⚠️ Limited design freedom

V-cut only works on straight lines and requires strict panel design rules. Once components move closer to the edge, options become limited.

⚠️ Unpredictable failure costs

The real cost of V-cut is often hidden: rework, scrap, and field failures—not the machine itself.

🛠️ When router depaneling is the better choice

✅ Dense and high-value PCBA

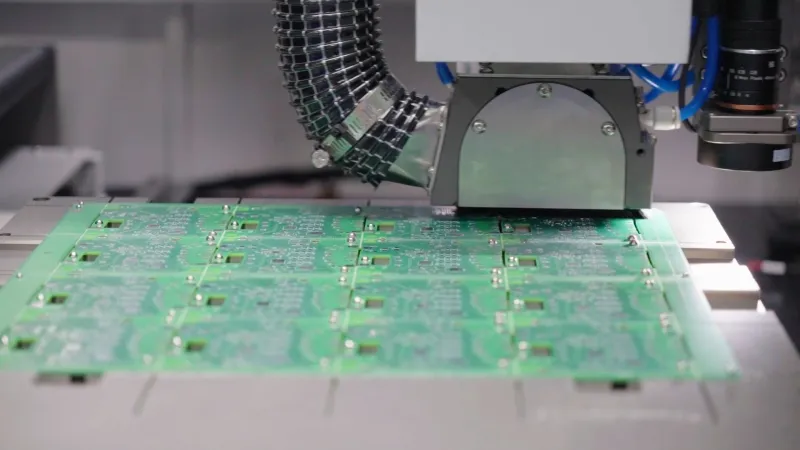

Router depaneling removes material instead of snapping boards apart. Cutting force stays local and controlled, which is critical for:

- HDI boards

- Fine-pitch components

- Edge-mounted connectors

✅ Components close to the PCB edge

If components sit within 1–2 mm of the edge, router depaneling offers much better protection. Engineers gain layout freedom without compromising reliability.

✅ Irregular board shapes

Curves, internal cutouts, and non-standard outlines are not a problem for router depaneling. This flexibility often simplifies panel design upstream.

💸 Cost analysis: short-term vs long-term

At first glance, V-cut looks cheaper:

- Lower machine cost

- Faster cycle time

But production data often tells a different story.

| Cost Factor | V-cut | Router Depaneling |

|---|---|---|

| Initial equipment | Low | Medium |

| Board stress | High | Low |

| Rework rate | Higher | Lower |

| Yield stability | Inconsistent | Stable |

| Design flexibility | Limited | High |

For medium- to high-value PCBA, router depaneling frequently lowers total cost per board, even with a higher upfront investment.

🧩 Case example: Industrial control boards

An industrial electronics manufacturer experienced unexplained field failures after switching to thinner PCBs. Initial checks showed no assembly defects. The issue traced back to V-cut-induced microcracks near ceramic capacitors.

After moving to a router depaneling solution supported by Сепреи, the results were clear:

- Post-depaneling defects dropped significantly

- Functional test yield stabilized

- Field return rates decreased

The depaneling change paid for itself within months.

🧠 Practical decision checklist

Choose router depaneling if you answer “yes” to any of these:

- Are components close to the board edge?

- Is the PCB thin, flexible, or high-density?

- Are reliability requirements strict (industrial, automotive, medical)?

- Do depaneling-related defects appear late in testing?

If all answers are “no,” V-cut may still be sufficient.

🔧 Solution mindset: design + process together

Depaneling should not be treated as a final step. The best results come when:

- PCB layout

- Panel design

- Depaneling method

are considered together early in the project. Router depaneling gives engineers more room to optimize without redesigning boards later.

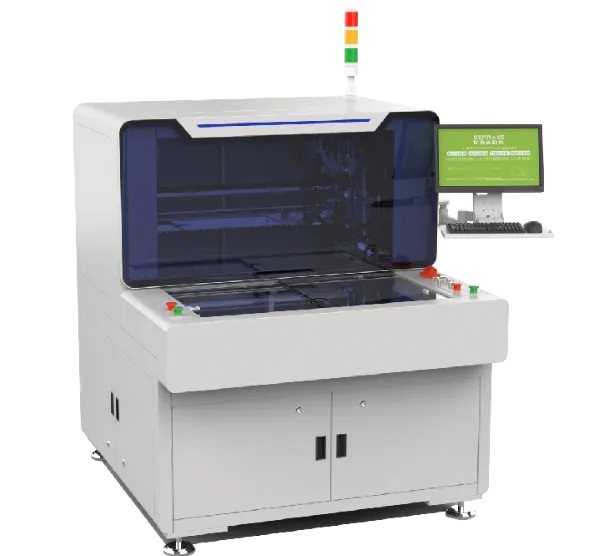

🌐 Why Choose Seprays Group?

Seprays Group focuses on low-stress, production-proven depaneling solutions for demanding PCBA applications. Our router depaneling systems are designed around:

- Stable cutting paths

- Controlled mechanical stress

- Long-term industrial durability

We work closely with manufacturers to reduce hidden depaneling risks and improve yield consistency.

If you are evaluating router depaneling for your next project, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)