🛠️ Overview: practical choices for constrained budgets

Top 5 Affordable PCB Depaneling Machines for Small Factories — for many small EMS and prototype shops in Germany and France, the right depaneling machine must balance industrial durability, repeatable accuracy, and low total cost of ownership. This guide highlights five machine types/models (by category), explains where they fit, and shows how small factories can save money without sacrificing quality.

⚙️ 1 — Compact Router Systems (Best all-rounder)

Compact router depaneling machines use a small high-speed spindle and CNC motion to cut panels with low stress. They are:

- Strengths: high edge quality, wide material compatibility (FR4, IMS), easy to program.

- Cost profile: moderate upfront, low consumable cost if you optimize spindle speed and feeds.

- Ideal for: small-batch automotive components, industrial controls, and mixed-product lines.

Case note: a French SME replaced manual routing with a compact router and cut scrap by ~60% while keeping capital expense manageable.

🔩 2 — Bench-top Saw Blade Units (Lowest entry cost for rigid boards)

Simple, benchtop saw machines are attractive when budgets are tight:

- Strengths: low initial price, straightforward maintenance.

- Limitations: mechanical contact produces dust and potential burrs; not ideal for very fine-pitch or flexible PCBs.

- Cost trade-off: cheap to buy, but watch for increased tool wear and cleanup labor.

Practical tip: pair with an effective dust extraction hood to protect optical modules and reduce rework.

💰 3 — Economical V-cut / Scoring Systems (Fast throughput for standard panels)

V-scoring machines (manual or semi-auto) excel with uniform panel layouts:

- Strengths: very fast for standard designs, minimal operator skill needed.

- Caveat: only works when board and panel design permit scoring; risk of board warpage if parameters are wrong.

- ROI: low capital and very quick payback on high-volume standard panels.

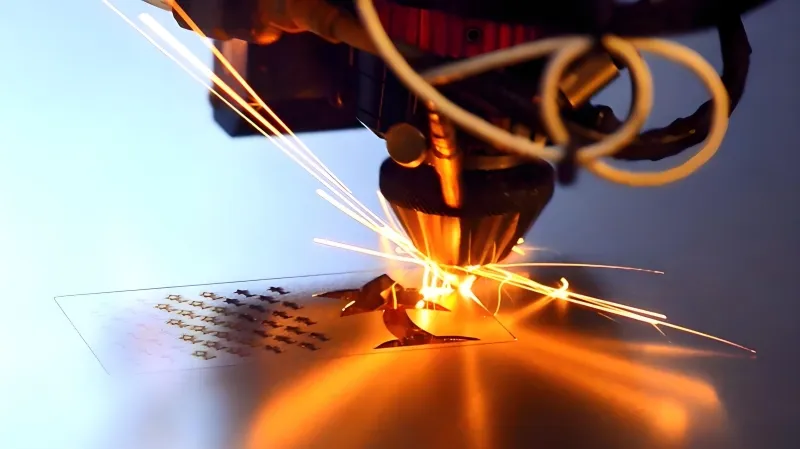

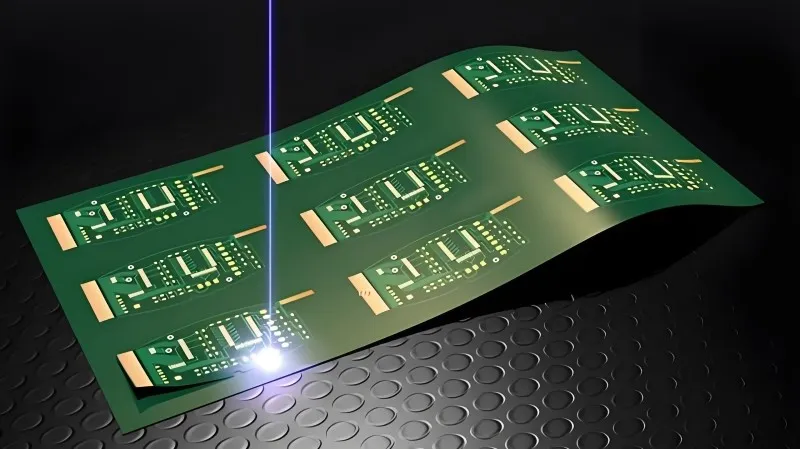

🧰 4 — Entry-Level Laser Depaneling (No-contact, low rework)

Small, lower-power laser systems now exist at more affordable price points:

- Strengths: contactless cutting, excellent for flexible circuits and RF boards, and minimal burrs.

- Limits: higher initial cost than small routers, requires fume extraction and trained operators.

- When to pick: if you run many flex or HDI boards and need zero mechanical stress.

🏭 5 — Multi-function Modular Cells (Scalable investment)

Modular cells combine a basic depaneling head (router or blade) with automated handling options:

- Strengths: Start small with manual loading, add tray handling, vision alignment, or automated loading later.

- Financial logic: spreads investment across phases — good for growing shops that expect higher volume but can’t invest all at once.

📉 Cost Analysis — look beyond the sticker price

Small factories often focus on purchase price, but the larger drivers of lifetime cost include:

- Tool consumption and replacement frequency

- Scrap and rework related to burrs or cracks

- Downtime during manual changeovers

- Labor for handling and inspection

A practical approach is to calculate the cost per good board: include capital amortization, tooling, energy, and labor. In many scenarios, a modestly higher capital spend on a router or entry laser reduces cost per board over 12–24 months.

🔍 Selection checklist for small factories

- Production mix: prototypes vs. repeat runs?

- PCB types: rigid, flex, thick copper?

- Floor space and staffing constraints.

- Service access and spare-part availability in the EU.

- Integration needs: Do you want MES/traceability later?

🗣️ Peer advice & case highlight

A small German workshop adopted a modular router cell with automatic tool-change and reduced operator touchpoints; outcome: throughput +35%, scrap −70%, and a payback under one year. Their secret: optimize nesting to increase material utilization and reduce routing travel.

✅ Why Choose Seprays Group?

Seprays Group provides a range of depaneling solutions designed for industrial robustness, easy maintenance, and EU serviceability. For small factories, we recommend modular, upgradeable systems that let you balance capital spending with operational gains. If you want a bespoke cost-per-board assessment or help choosing the right machine for your product mix, please contact Seprays Group — we’ll help match technology to your production and budget constraints.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)