A PCB depaneling machine is an essential tool in modern electronics manufacturing. It separates individual printed circuit boards (PCBs) from a larger panel with precision, speed, and minimal stress. Instead of relying on manual cutting or breakaway tabs, a depaneling machine ensures consistent quality and protects delicate components.

⚙ What is a PCB Depaneling Machine?

A PCB depaneling machine is designed to cut or route PCBs out of a production panel. Assemblers use panels to save space, but at the final stage, they separate them into individual boards.

There are several types of depaneling machines:

- Milling cutter depanelers – use high-speed rotating blades.

- Laser depanelers – cut with precision beams, no mechanical stress.

- V-scoring depanelers – separate along pre-scored lines.

- Punching the depanelers – stamping out boards quickly.

Each method has its strengths, depending on the application.

💡 How Does a PCB Depaneling Machine Work?

The working principle depends on the depaneling method. Here’s how it typically works:

- Panel Loading – The PCB panel is placed into the machine manually or automatically.

- Positioning & Alignment – Cameras or guides align the board for precise cutting.

- Cutting Process – The machine separates the boards using milling, laser, or scoring technology.

- Dust Extraction – Milling machines use vacuum systems to remove dust.

- Board Collection – Finished boards are collected for further assembly or testing.

The entire process ensures smooth edges, low stress, and high repeatability.

📏 Why Precision Matters

Cutting accuracy is critical. A PCB depaneling machine with ±0.02 mm precision guarantees:

- Clean edges with no burrs.

- Minimal mechanical stress.

- Consistent quality across large production runs.

This precision directly impacts yield and reduces costly rework.

💎 Benefits of Using a PCB Depaneling Machine

Manufacturers who invest in advanced depaneling technology gain:

- Low stress separation – protects solder joints and components.

- Mirror-smooth edges – essential for downstream processes.

- Higher yields – fewer defects and less waste.

- Faster production – automation reduces manual labor.

The result is better efficiency and improved product reliability.

🏭 Industries That Rely on PCB Depaneling

- Medical devices require flawless reliability.

- Automotive electronics – must resist vibration and heat.

- Consumer electronics – demand fast production and high quality.

- Telecommunication equipment – relies on precise, stress-free boards.

A PCB depaneling machine supports these industries with consistent, high-performance results.

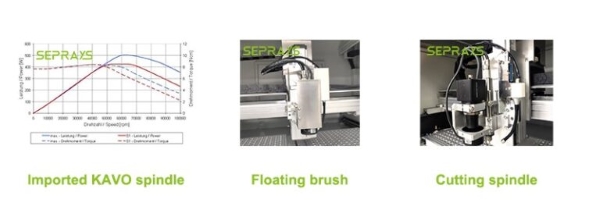

🚀 Advanced Features in Modern Machines

Today’s machines include:

- Automated loading/unloading for speed.

- Powerful dust collection for cleaner operation.

- ESD protection to prevent static damage.

- Smart software integration for MES/ERP traceability.

These features make production safer, cleaner, and more efficient.

💡 Why Choose Seprays Group?

At Seprays Group, we specialize in PCB depaneling machines that deliver:

- ±0.05 mm cutting accuracy.

- 300 μe low stress separation.

- Mirror-smooth edges for reliable assembly.

- Automated 24/7 operation to maximize efficiency.

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

📧 Contact us today to discuss your production needs and discover how Seprays can improve your PCB depaneling process.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)