This is a common question for PCB and PCBA engineers facing tighter tolerances, denser layouts, and rising cost pressure. The short answer: choose laser depaneling when mechanical stress, edge quality, or design freedom becomes a limiting factor. Below is a practical, experience-based breakdown to help you decide.

🔍 Understanding the Core Difference

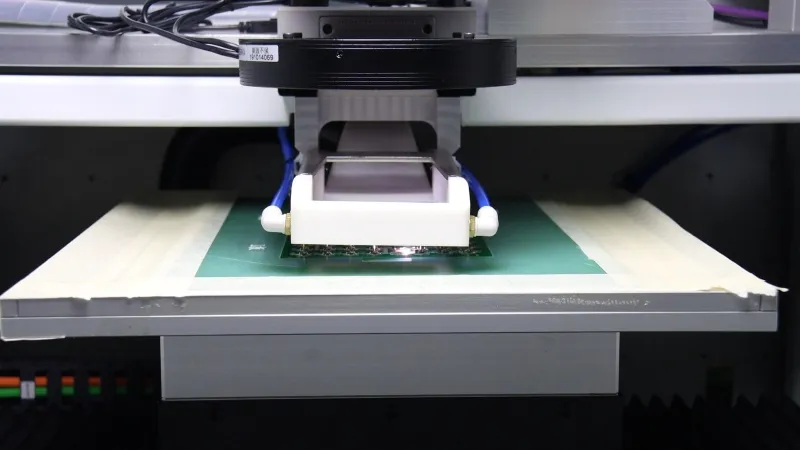

Routing (milling) relies on physical contact between a rotating tool and the PCB. Laser depaneling, by contrast, uses a focused laser beam to separate boards without contact.

The real difference shows up in stress, precision, and design flexibility—not just cutting speed.

⚠️ Key Pain Points with Traditional Routing

Engineers often start questioning routing when they encounter these issues:

- Micro-cracks or solder joint failures after depaneling

- Component keep-out zones are becoming larger due to the tool diameter

- Frequent tool wear, replacement, and downtime

- Noise, dust, and vibration are affecting the inline processes

Routing works well for many standard FR-4 panels, but as boards get thinner and layouts denser, its limits become visible.

🎯 When Laser Depaneling Makes More Sense

You should seriously consider laser depaneling over routing if your project involves:

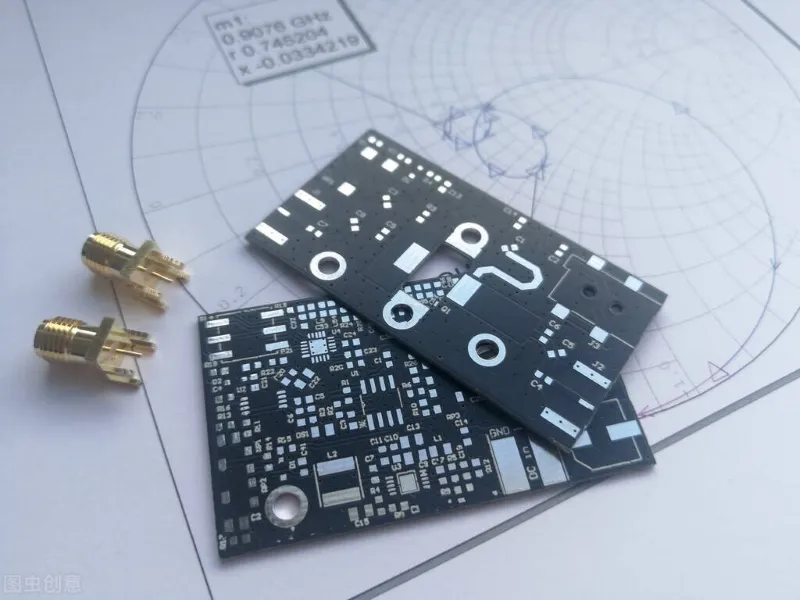

- High-density PCBA with components close to the board edge

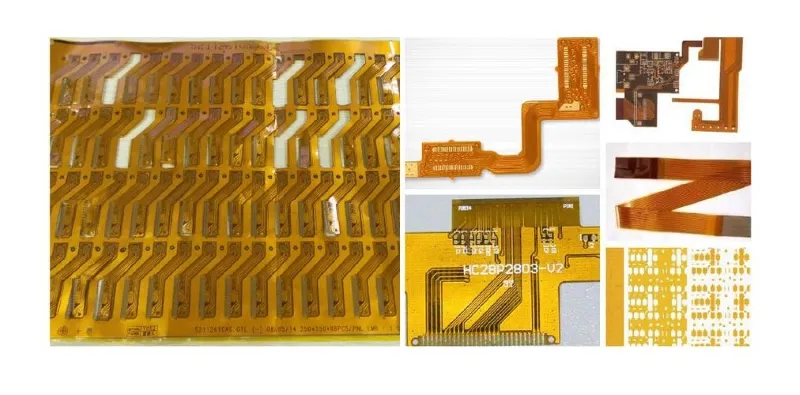

- Flexible, rigid-flex, or ultra-thin substrates

- Irregular outlines or non-linear cutting paths

- Strict stress control requirements, such as automotive or medical electronics

In these scenarios, even well-optimized routing can introduce risks that are hard to eliminate.

💰 Cost Analysis – Looking Beyond the Machine

At first glance, laser systems appear more expensive. But the total cost of ownership tells a different story:

- No cutting tools, blades, or molds to replace

- Reduced scrap from edge damage or micro-cracks

- Higher material utilization due to ultra-narrow kerf

- Less maintenance-related downtime

For low- to mid-volume, high-mix production, laser depaneling often balances out—or even lowers—overall costs over time.

🧪 Real-World Case Insight

A customer producing automotive sensor modules faced recurring post-assembly failures traced back to depaneling stress. Routing met throughput needs but caused invisible mechanical strain.

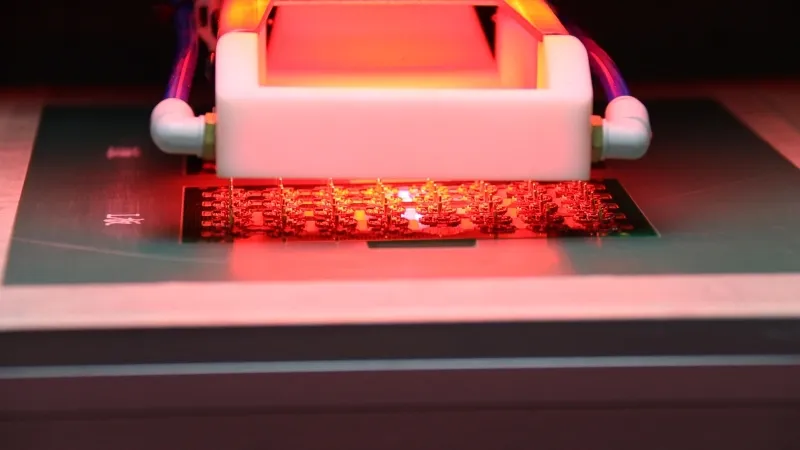

After testing a Seprays laser depaneling system, they achieved:

- Clean edges with no mechanical stress

- Stable yields across thin and rigid-flex panels

- Improved panel utilization thanks to finer cutting paths

The switch didn’t replace routing everywhere—but it solved the critical bottleneck where reliability mattered most.

🛠️ Practical Selection Guidelines

Laser depaneling is not a universal replacement. A balanced approach works best:

- Use routing for thick, simple FR-4 panels and high-volume cost-driven lines

- Use laser depaneling for precision-critical, fragile, or complex designs

The question isn’t routing or laser—it’s where each method performs best.

⚡ Seprays Laser Depaneling Advantages

Seprays focuses on precision-driven applications where consistency matters:

- Ultra-high precision (<2 μm)

- No mechanical stress or vibration

- Extremely narrow kerf (<25 μm), improving material utilization

- Free-form cutting without design constraints

- No consumables like blades or molds

- Clean, residue-free cuts

- Fast and automation-friendly for inline production

These features directly address the pain points that push engineers away from routing.

⭐ Why Choose Seprays Group?

Seprays Group combines depaneling process knowledge with application-driven laser solutions. We focus on helping manufacturers choose the right method—not just selling machines.

If you’re evaluating whether laser depaneling is the right fit for your boards, contact us for a technical discussion or sample test.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)