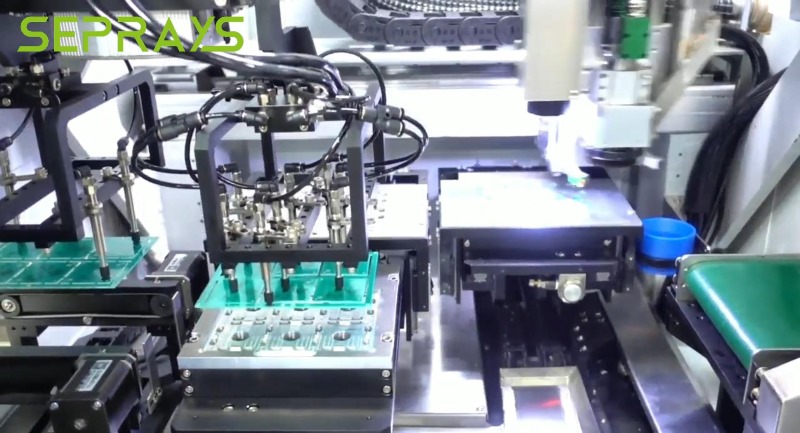

⚙ A fully automatic depaneling machine has become the most efficient and accurate choice for PCB depaneling in modern electronics manufacturing. As devices get smaller, faster, and more complex, traditional manual methods cannot keep pace. These machines provide high precision, low stress, and consistent performance, making them essential for mass production.

✂️ Why PCB Depaneling Needs Automation

Manual separation of printed circuit boards often causes stress and defects. Cracks, solder joint damage, and uneven edges are common issues.

A fully automatic depaneling machine solves these problems by using advanced cutting methods and controlled force. This ensures cleaner edges, safer components, and higher yields.

📏 Accuracy That Drives Reliability

Precision is critical in PCB manufacturing. Even a small error in board separation can impact assembly and long-term performance.

Modern depanelers deliver repeatability of ±0.02 mm. This level of accuracy guarantees that each board fits perfectly into housings and downstream processes. It also reduces the risk of rework or product failure.

🚀 Efficiency for High-Volume Production

Electronics manufacturers face constant pressure to produce more in less time. Fully automatic depanelers improve efficiency by:

- Reducing cycle times.

- Replacing manual labor with automated workflows.

- Ensuring consistent separation across hundreds of boards per hour.

This results in faster time-to-market and better use of factory resources.

🛡 Protecting Sensitive Components

PCBs are packed with delicate chips and connectors. Manual stress can bend, crack, or weaken these parts.

A fully automatic depaneling machine applies controlled methods such as V-cut, milling, or laser cutting. This reduces mechanical strain, keeping solder joints intact and preventing hidden damage.

🧹 Cleaner and Safer Manufacturing

Dust and static are hidden threats during PCB separation. Many advanced depanelers include:

- Dust collection systems for cleaner boards.

- ESD protection to safeguard components.

These features reduce contamination, extend product life, and enhance reliability.

🌍 Applications Across Industries

From high-tech to everyday devices, the demand for fully automatic depaneling machines is growing:

- Automotive electronics – sensors, control modules, and safety systems.

- Medical equipment – precision boards where reliability is critical.

- Telecom hardware – routers, switches, and 5G boards.

- Consumer electronics – smartphones, wearables, and tablets.

- LED lighting – high-volume production with consistent quality.

In every sector, efficiency and accuracy translate into better results.

🔮 The Future of Depaneling

As PCBs continue to evolve, depaneling machines will become smarter and more flexible. Features like AI-driven vision alignment and adaptable cutting methods will make automation even more powerful.

This ensures manufacturers can keep up with new designs while protecting quality and yield.

💡 Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

We help manufacturers around the world reduce costs, improve quality, and stay competitive in fast-moving markets.

📧 If you need support, please contact us today.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)