The SEPRAYS GAM336AD is redefining how manufacturers handle PCB depaneling.

If your production line struggles with speed, precision, or labor costs, this automatic PCB router offers the perfect upgrade — clean, fast, and fully automated.

In the age of high-efficiency manufacturing, staying slow isn’t an option. Let’s explore how this machine turns cutting challenges into smooth, seamless performance.

⚙️ The Challenge: Slow PCB Cutting Hurts Productivity

Every second counts in PCB manufacturing.

Manual or outdated depaneling systems not only slow down throughput but also risk damaging delicate boards.

Vibration, human error, and inconsistent cutting lead to stress cracks and costly rework.

The result? Lower yield, higher expenses, and reduced production flexibility.

Manufacturers need a smarter solution — one that keeps up with modern demands.

🚀 The SEPRAYS GAM336AD Advantage

The SEPRAYS GAM336AD combines automation, accuracy, and intelligent control into one powerful system.

Key features include:

✔ CCD vision for precision

✔ High-speed spindle & auto tool-change

✔ Dual worktables for nonstop production

✔ Automatic sorting & tray loading — zero manual errors

✔ Clean, efficient, and cost-saving

This isn’t just a depaneling machine — it’s a complete productivity solution.

🎯 CCD Vision for Precision Alignment

Every PCB design demands accuracy down to microns.

That’s why the SEPRAYS GAM336AD comes equipped with a high-speed CCD vision system.

It automatically identifies fiducial marks, adjusts cutting paths, and ensures every cut lands exactly where it should.

No more guesswork — just consistent, repeatable results for every batch.

⚡ High-Speed Spindle with Auto Tool-Change

Speed meets intelligence.

The GAM336AD integrates a high-speed spindle with an automatic tool-changing system that minimizes downtime.

When the cutting bit wears out, the system switches tools instantly, maintaining stable quality throughout production.

This feature maximizes uptime and extends machine life — perfect for 24/7 operations.

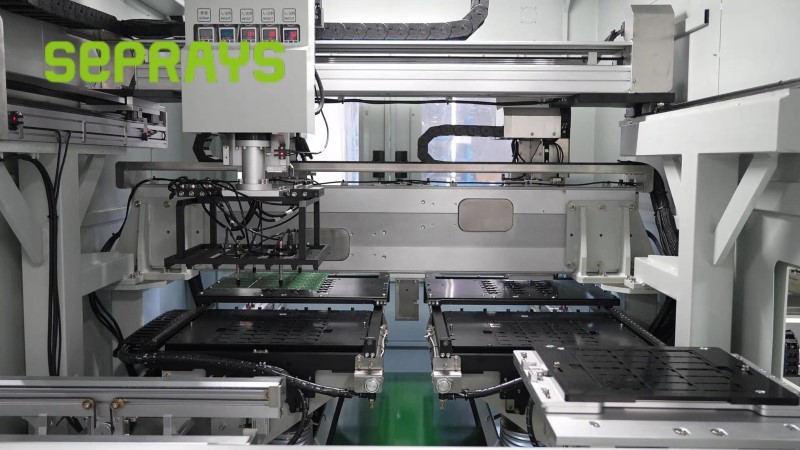

🔁 Dual Worktables for Continuous Operation

No waiting. No wasted time.

The SEPRAYS GAM336AD features dual worktables that allow one board to be cut while another is loaded.

This parallel design eliminates idle moments and boosts overall throughput.

Operators can prepare the next job while the machine continues cutting, creating a truly uninterrupted workflow.

🧠 Automatic Sorting & Tray Loading

Forget manual handling and sorting errors.

The GAM336AD automates the post-cut process with intelligent sorting and tray loading.

Boards are placed directly into designated trays, organized by type or process stage.

It’s faster, cleaner, and ensures full traceability in your production line.

🌿 Clean, Efficient, and Cost-Saving

Clean production means reliable products.

The SEPRAYS GAM336AD minimizes dust generation during cutting and supports efficient vacuum extraction.

Low-vibration cutting reduces component stress, while automation cuts labor costs dramatically.

Over time, the result is a leaner, more sustainable manufacturing process — with faster ROI.

🧩 Ready for Smart Manufacturing

In an era where automation drives competitiveness, the GAM336AD is built for integration.

It connects smoothly with SMT lines, robotic arms, and MES systems, supporting data-driven production management.

From real-time monitoring to predictive maintenance, it fits perfectly within your smart factory strategy.

🌟 Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

We combine advanced engineering with reliable service support, helping manufacturers achieve higher yields and smoother production.

If your production line is ready for the next step in automation, we’re here to help.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)