PCB depaneling efficiency in SMT lines is one of the most overlooked yet critical factors that directly affects production throughput, yield, and total manufacturing cost. As electronics manufacturers face increasing demand for miniaturization and mass customization, improving depaneling performance has become essential to stay competitive.

This article explores five practical ways to boost PCB depaneling efficiency, reduce operator dependency, and enhance long-term reliability—based on real-world factory experiences and engineering insights from SEPRAYS.

🧩 1. Optimize Cutting Technology Selection

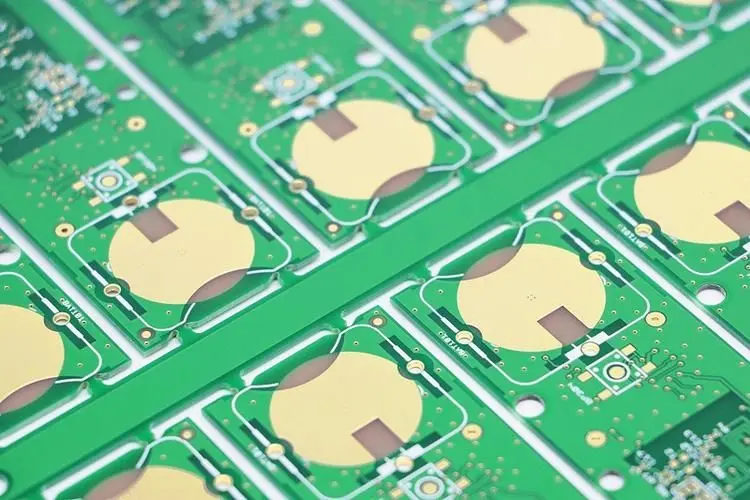

Choosing the right depaneling method is the foundation of efficiency. Each technology—router, laser, V-cut, or punching—has distinct strengths:

- Router machines provide flexible cutting paths and precise edge quality, ideal for complex board geometries.

- 激光分板 ensures stress-free, contactless cutting, perfect for fine-pitch or flexible circuits.

- V-cut and punching systems offer ultra-fast throughput for standardized panel designs.

Factories often gain the best results through hybrid setups, combining router and laser machines to balance accuracy and speed.

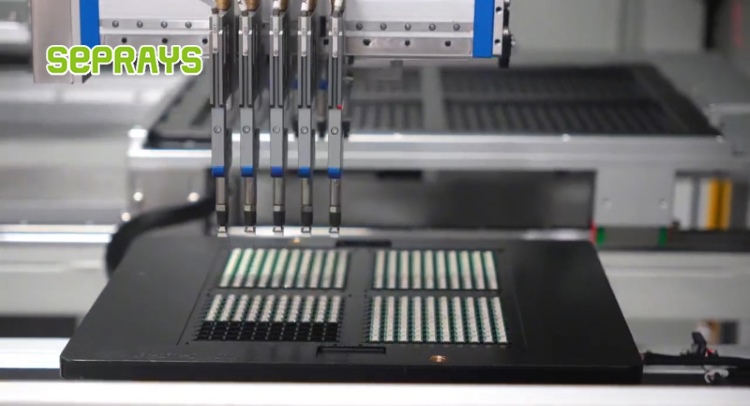

⚙️ 2. Integrate Automation for Handling and Positioning

Manual handling of PCBs after cutting can lead to misalignment, microcracks, and productivity losses. Integrating automated tray handling and robotic loading/unloading significantly streamlines the depaneling process.

Modern SMT lines now pair depaneling machines with:

- Vision-guided robots for pick-and-place after cutting.

- Conveyor integration to sync directly with reflow or testing lines.

- Smart vacuum fixtures for accurate PCB fixation during routing.

One SEPRAYS customer in Eastern Europe achieved a 25% reduction in total cycle time by upgrading from manual loading to fully automated tray handling.

💡 3. Implement Intelligent Feed Rate and Spindle Control

Many manufacturers still rely on static feed and speed parameters. However, different board materials (e.g., FR4, aluminum, polyimide) require unique spindle and feed rate combinations.

Advanced PCB depaneling machines now feature AI-assisted feed optimization, adjusting tool speed based on:

- Material density

- Routing path complexity

- Real-time spindle load

This dynamic control ensures consistent cutting pressure, reduces tool wear, and minimizes stress transfer to delicate components.

🔍 4. Use Real-Time Process Monitoring and Data Feedback

Efficiency isn’t only about faster cutting—it’s about maintaining stable quality with less downtime. By integrating IoT sensors and process analytics, factories can monitor:

- Tool wear and vibration levels

- Air pressure and dust collection performance

- Board temperature and cutting debris levels

This data-driven approach enables predictive maintenance, ensuring that the depaneling system operates at optimal parameters throughout production.

For instance, one Asian OEM using SEPRAYS’ monitoring system reported a 40% reduction in unplanned stoppages by replacing tools only when necessary, not by arbitrary time intervals.

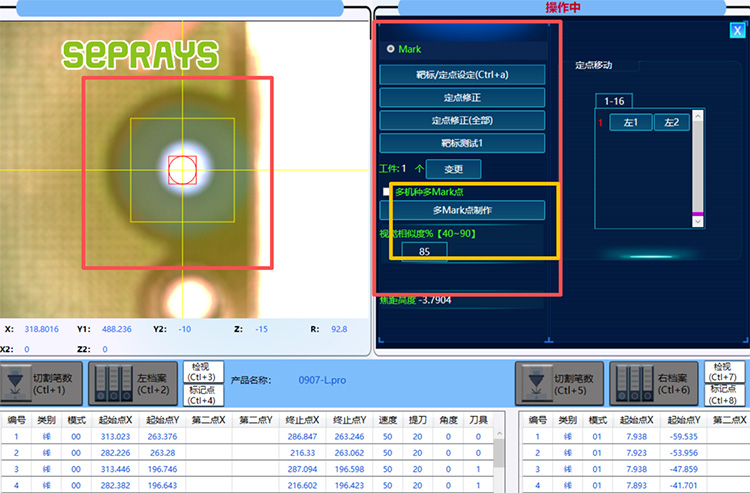

🧠 5. Reduce Setup Time through Smart Programming

Traditional depaneling setups require engineers to manually define cutting paths—a time-consuming process, especially when handling multiple product types.

With vision-assisted programming and auto-teaching systems, modern depaneling equipment can automatically detect fiducial marks, align cutting paths, and even compensate for panel warpage.

The result? Faster product changeovers, fewer operator errors, and shorter downtime between batches.

Factories implementing smart path recognition have seen overall efficiency gains of 30–50%, especially in high-mix production environments.

🏭 Case Study: European SMT Line Boosts Efficiency by 60%

A German electronics manufacturer producing automotive control units faced a bottleneck in PCB separation. After replacing manual depaneling stations with SEPRAYS router machines featuring automatic tool changers and real-time process control, they achieved:

- 60% higher throughput

- 50% fewer cutting defects

- 35% lower tool consumption

The factory was able to reassign two operators to other critical tasks, improving labor utilization without sacrificing quality.

💬 Final Thoughts: Efficiency Is a Continuous Process

Improving PCB depaneling efficiency in SMT lines isn’t a one-time upgrade—it’s an ongoing optimization combining the right equipment, automation, and process intelligence.

By understanding your production constraints and continuously analyzing performance data, you can strike the ideal balance between speed, precision, and cost.

🌍 Why Choose Seprays Group?

With 30+ years of experience in PCB/FPC depaneling, Seprays Group delivers cutting-edge solutions that enhance productivity and precision for global manufacturers. Our product portfolio includes:

- Router, laser, V-cut, and punching depaneling machines.

- Integrated tray handling and robotic automation.

- Smart vision and AI-based optimization systems.

- Global technical support and localized service.

Whether you’re upgrading a single line or building a fully automated factory, Seprays Group provides reliable, scalable solutions to meet your SMT production goals.

If you’re looking to elevate your depaneling efficiency, contact Seprays Group today — let’s build smarter production lines together.

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)