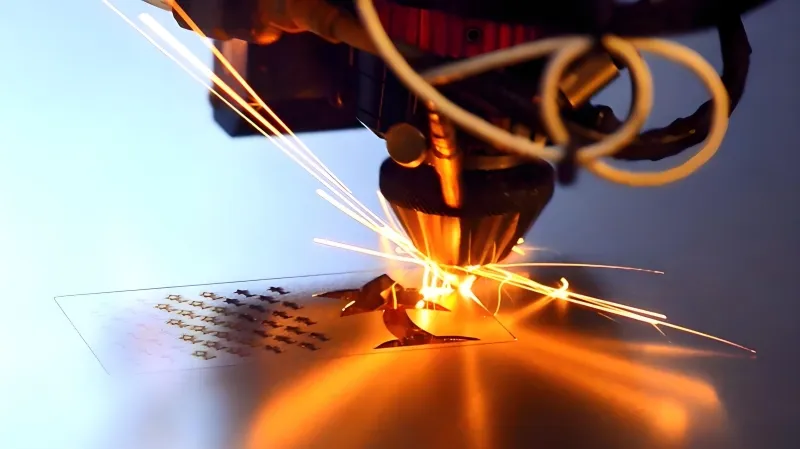

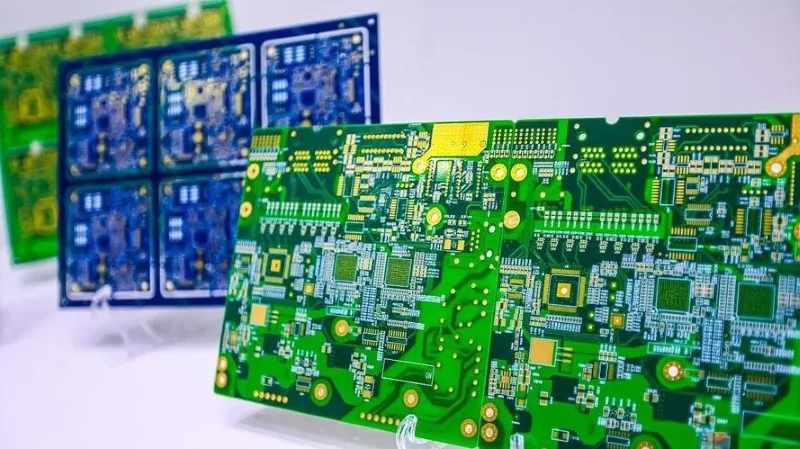

PCB Milling Depaneling Machine has become a cornerstone for high-value, high-density PCBAs where precision, edge integrity, and component safety are critical. Unlike V-cut or blade depaneling, milling provides controlled material removal and is especially effective for dense layouts, fragile boards, and applications demanding high reliability. This article explores practical strategies, common challenges, and field-tested solutions shared by engineers in global SMT environments.

⚙️ Understanding the Importance of Edge Accuracy

For high-value PCBAs, edge accuracy is not just cosmetic—it affects:

- Mechanical fit in housings or connectors

- Solder joint reliability for edge-mounted components

- Performance of high-frequency traces near panel edges

Even slight deviations or burr formation can result in micro-cracks, electrical shorts, or customer returns, highlighting the need for precise milling parameters and fixture support.

🧩 Challenge 1: Spindle Vibration and Tool Wear

Field engineers frequently report that spindle vibration or dull milling bits are primary sources of edge inconsistency. Effects include:

- Uneven cut depth leading to stress on edge components

- Surface roughness that affects coating or potting adhesion

- Hidden micro-cracks revealed only in reliability testing

Best practices involve monitoring tool wear, calibrating spindle runout, and implementing preventive maintenance schedules. Some high-density automotive PCBA lines saw a 25% reduction in edge defects by following these steps.

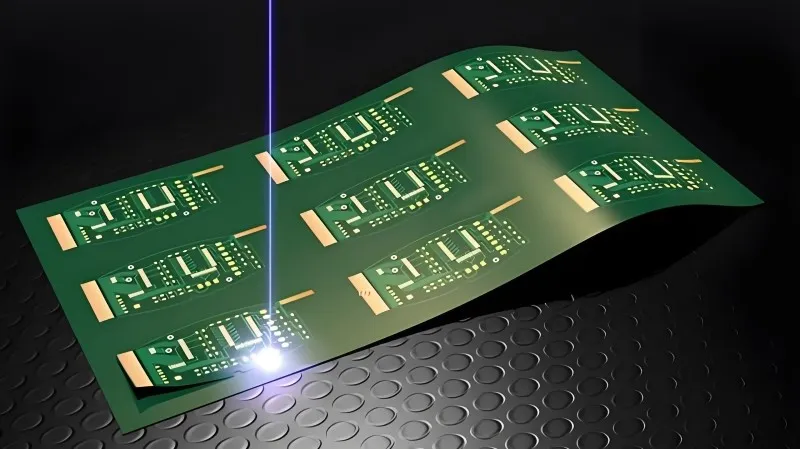

🪚 Challenge 2: Panel Flex and Support

Thin or large-format PCB panels can flex during milling, especially when multiple boards are processed simultaneously. Panel flex can transfer stress into populated areas, causing:

- Cracked ceramic capacitors or solder joints

- Component shift during depaneling

- Latent field failures

Solutions include using full-surface vacuum fixtures, adaptive clamping, and sequencing milling paths to reduce bending moments.

🔧 Challenge 3: Dust and Contamination Management

Milling generates fiberglass, resin dust, and particulate debris that can settle on high-density components or under solder mask layers. Industrial teams recommend:

- Integrated dust extraction close to the cutting point

- Routine cleaning of fixtures and panels

- Inline optical inspection to detect edge debris

Proper dust control not only preserves edge quality but also reduces secondary cleaning steps and inspection time.

📉 Cost Analysis: Milling Investment vs. Yield Protection

Although milling depaneling machines may have higher upfront costs than traditional blade systems, hidden benefits include:

- Reduced scrap from micro-cracks or edge damage

- Fewer warranty claims and field failures

- Lower rework and inspection overhead

Several EMS providers report that optimizing milling parameters and fixtures reduced total cost per board, even for high-throughput production lines.

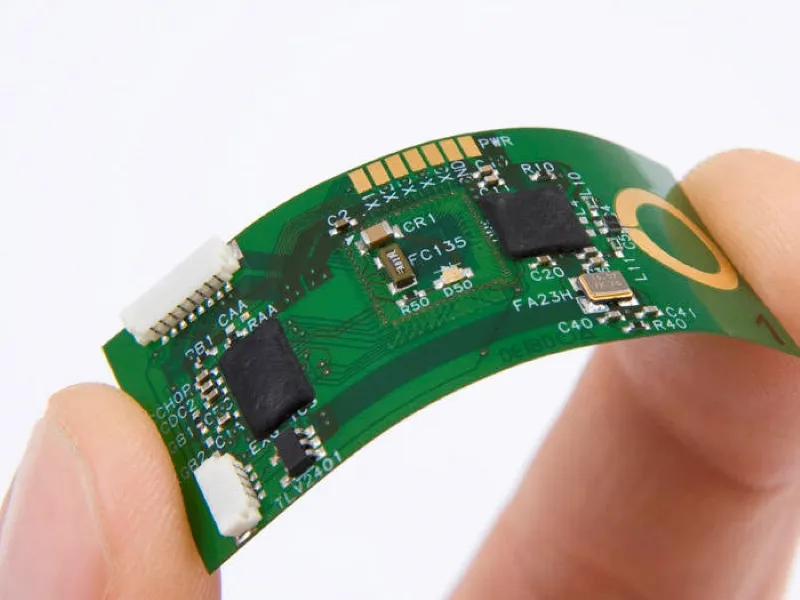

🏭 Case Insight: Medical Device PCBAs

A medical electronics manufacturer observed intermittent failures in flex-rigid connectors during vibration tests. After transitioning from a standard V-cut system to precision milling with vacuum fixtures, edge integrity improved significantly, and defect rates dropped by 35% without changing component layout.

🛠️ Practical Takeaways for Engineers

- Treat milling and depaneling as a reliability-critical process

- Monitor spindle vibration, tool wear, and fixture alignment continuously

- Match milling strategies to PCB density, thickness, and material composition

- Validate edge quality through reliability testing, not just AOI

By combining proper fixturing, tool management, and parameter optimization, milling depaneling can consistently deliver industrial-grade edge precision.

💬 Why Choose Seprays Group?

Seprays Group provides high-quality milling depaneling solutions focused on edge accuracy, stress control, and durable performance for high-value PCBAs. Our expertise helps manufacturers optimize milling for dense, fragile boards across automotive, medical, and industrial applications.

If you would like to discuss milling depaneling optimization or explore suitable solutions for your SMT line, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)