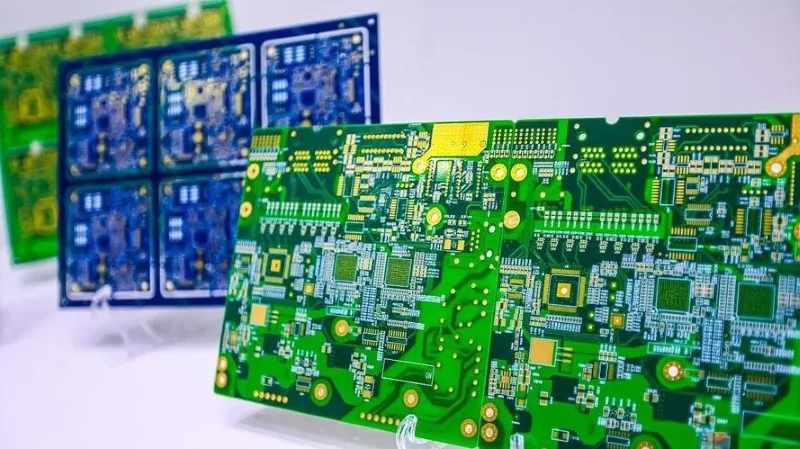

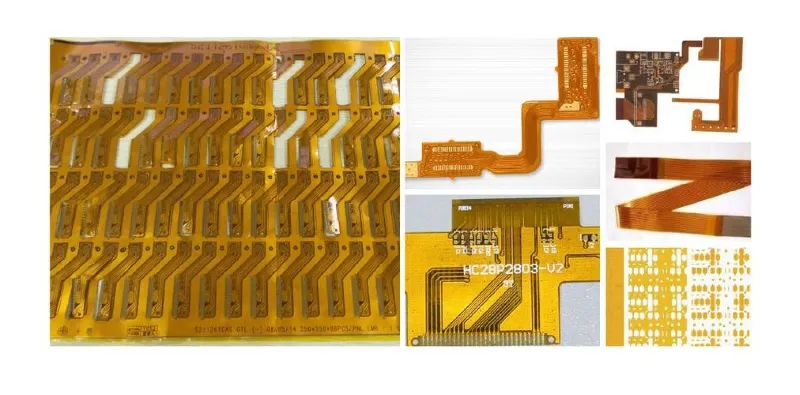

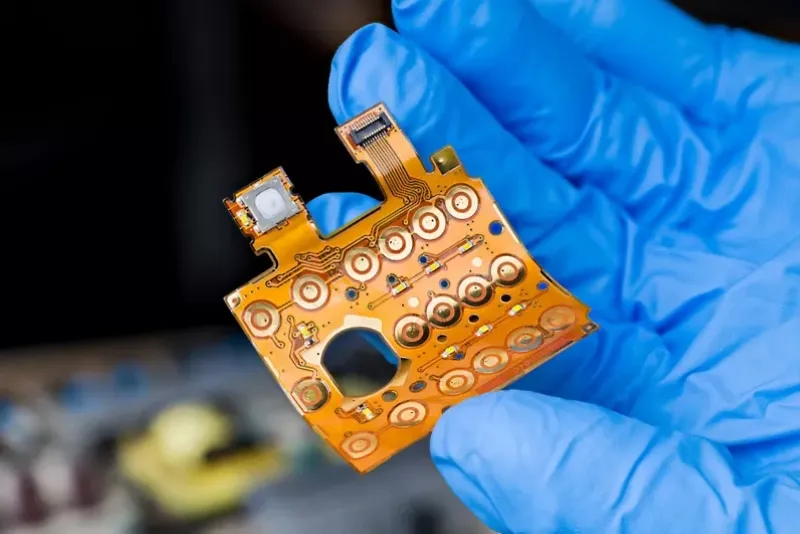

Laser depaneling for flexible PCBs is increasingly popular in high-density electronics. Flexible PCBs are thin, stress-sensitive, and often densely populated. Mechanical methods like routing or V-cut can introduce micro-cracks, fiber pull-out, or board warping. Laser depaneling removes these risks, making it highly suitable when applied correctly.

This article shares practical insights, production challenges, and cost considerations, with examples from EMS and OEM lines, including selective use of Seprays-supported laser depaneling.

🔍 Why Flexible PCBs Need Special Care

Flexible PCBs bend and twist easily. Even minor mechanical stress during depaneling can lead to:

- Broken traces or micro-cracks

- Poor solder joint reliability

- Yield loss during thermal cycling

For high-value products—automotive sensors, wearables, medical electronics—avoiding stress is critical. Laser depaneling eliminates mechanical contact, directly addressing these pain points.

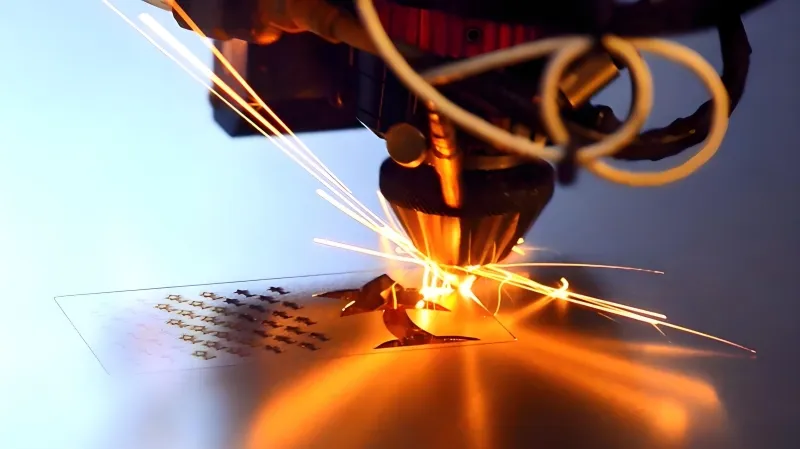

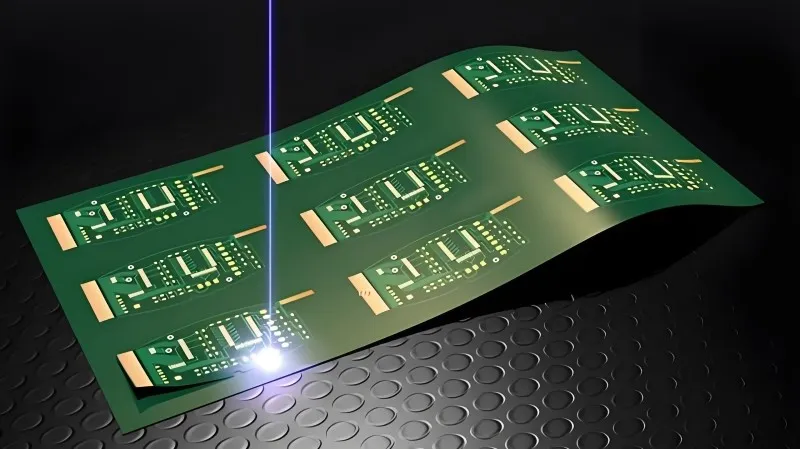

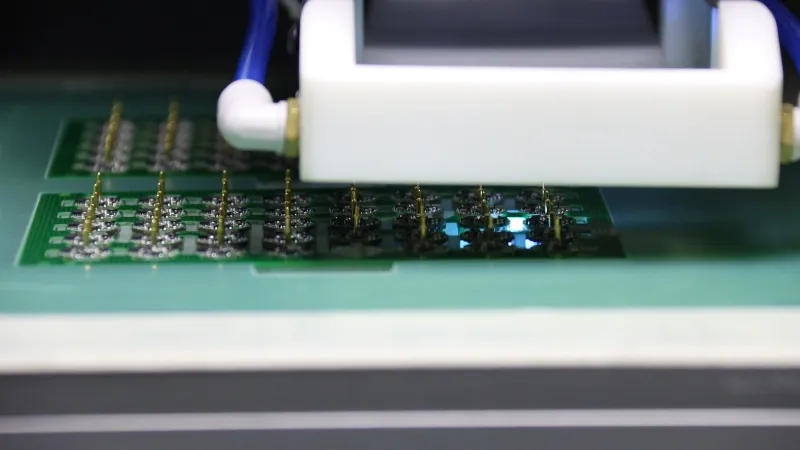

⚙️ How Laser Depaneling Works on Flexible PCBs

Laser depaneling uses a focused light beam to ablate PCB material without physical contact. Key effects for flex PCBs:

- No mechanical force prevents bending or vibration damage

- Precise, controlled energy input avoids delamination

- Clean edges reduce fiber pull-out

Compared with routing, laser depaneling spreads cutting energy over time rather than applying instantaneous stress.

✨ Advantages of Laser Depaneling for Flexible PCBs

Field experience shows these benefits:

- High precision (<2 μm) ensures accurate cutting even near components

- Zero mechanical stress and vibration, preserving delicate copper traces

- Ultra-narrow kerf (<25 μm) increases usable PCB area and reduces material waste

- Free-form cutting allows complex outlines

- No consumables like blades or molds

- Clean, stain-free edges, ready for assembly

- Fast processing for thin and small panels

Flexible PCBs benefit more than rigid boards, especially in dense layouts or when components are close to the edge.

💡 Production Insights and Pain Points

In real EMS lines:

- V-cut or routing caused micro-cracks in the FPC layers for wearable devices

- Rework increased due to trace damage at the corners

- Yield loss was particularly high in high-volume automotive control boards

Introducing Seprays-supported laser depaneling, selectively for these high-risk boards, reduces defects and stabilizes production. Boards maintained reliability through thermal and mechanical testing without additional tooling.

💰 Cost Analysis

While laser depaneling systems require higher upfront investment, total lifecycle costs often decrease:

- Lower scrap and rework rates

- No tooling or consumable replacement

- Reduced assembly line failures due to edge damage

For flexible PCBs with tight tolerances, the cost is often justified by the improved yield and reduced warranty risk.

🏭 Case Example: Automotive and Wearable Electronics

In a wearable device project, flexible PCBs suffered occasional edge cracks during routing. EMS teams implemented Seprays-supported laser depaneling for selected SKUs:

- Cracks disappeared completely

- Edge quality became uniform

- Throughput remained acceptable due to parameter optimization

This selective approach highlights that laser depaneling doesn’t need to replace all processes—just where stress-sensitive boards require it.

🛠️ Guidelines for Flexible PCB Laser Depaneling

- Use a laser for thin, high-density, or stress-sensitive boards

- Validate material compatibility before production

- Avoid one-size-fits-all: mix routing, V-cut, and laser as needed

- Monitor yield and edge quality continuously

Laser depaneling is a tool, not a blanket solution. Applied intelligently, it maximizes yield and material efficiency.

🌍 Alignment with Global Trends

Flexible electronics are growing in automotive, medical, and wearable devices. Stress-free depaneling is becoming a standard expectation, especially in high-reliability products.

💬 Why Choose Seprays Group?

Seprays Group provides precision laser depaneling solutions tailored for flexible PCBs. We help manufacturers select the right depaneling method based on material, layout, and reliability requirements. By focusing on real production data and targeted applications, Seprays ensures stress-free, high-yield results.

If you want to evaluate whether laser depaneling fits your flexible PCB application, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)