In most real production environments, yes—saw blade depaneling is usually faster, but speed alone rarely tells the full story. The better question engineers ask after a few projects is: faster for which boards, at what cost, and with what long-term risk?

This article breaks the answer down from a production and reliability perspective.

⚡ Short answer first

- Saw blade depaneling → Faster linear cutting, ideal for straight-line separation and high-volume output

- Routing depaneling → Slower per board, but more flexible and safer for complex or sensitive designs

Speed matters—but only when it doesn’t compromise yield.

🧩 Where the speed difference really comes from

🔪 Cutting path length

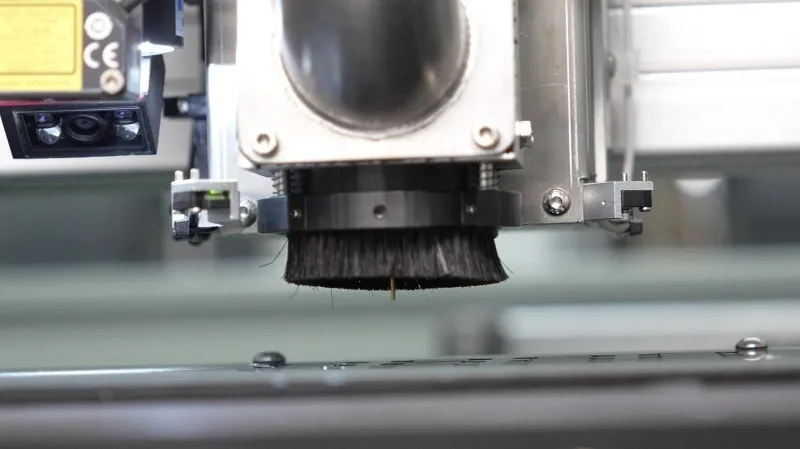

Saw blade depaneling follows straight, continuous lines. Once aligned, the blade cuts through the panel in a single motion. Routing removes material gradually, following programmed paths, which naturally takes longer.

🔄 Tool motion

Routing involves frequent acceleration, deceleration, and direction changes. Saw blade systems maintain constant linear motion, which is why cycle times are shorter.

In high-volume SMT lines, this difference becomes very noticeable.

⚠️ The hidden trade-offs engineers notice later

🧱 Mechanical stress

Saw blade depaneling applies force along the cut line. While well-designed machines control this force, stress is still higher than routing, especially on thin or dense PCBAs.

📐 Design limitations

Saw blades work best with:

- Straight edges

- Uniform panel layouts

If your board shape is complex or components sit close to the edge, routing may still be safer—even if slower.

💸 Cost analysis: speed vs total cost

At first glance, faster cutting looks cheaper. But production teams often evaluate cost differently after a few batches.

| Factor | Saw Blade | Routing |

|---|---|---|

| 切割速度 | Very high | 介质 |

| Tool wear | Low–medium | Higher |

| Board stress | 介质 | Low |

| Design flexibility | Limited | High |

| Rework risk | Process-dependent | Lower |

If defects appear after depaneling, any time saved at cutting is quickly lost downstream.

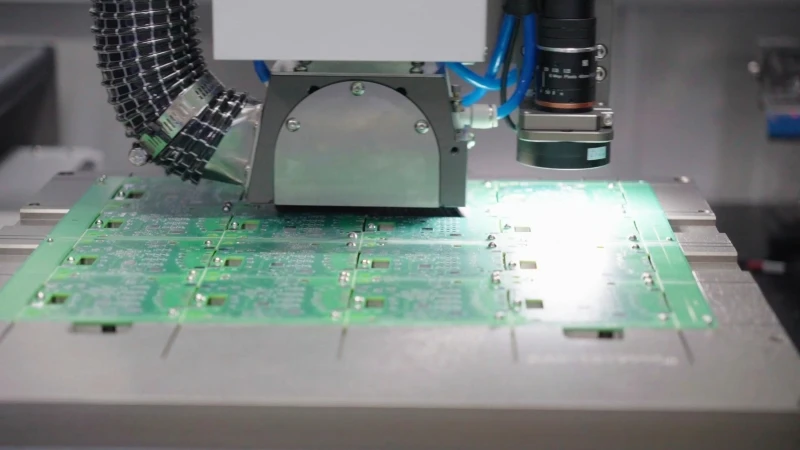

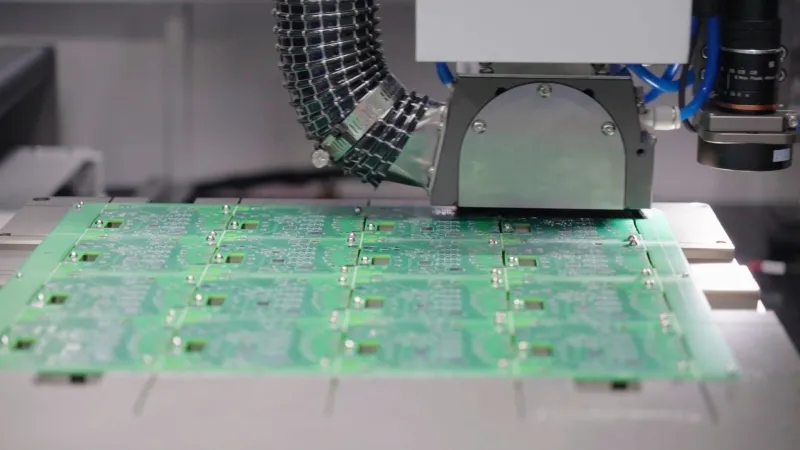

🏭 Case insight: consumer electronics line

A consumer electronics manufacturer needed to increase output for a new product with rectangular boards and validated edge clearance. After switching from routing to a saw blade depaneling solution provided by Seprays, they achieved:

- Shorter cycle time per panel

- Stable edge quality

- No measurable increase in depaneling-related defects

In this case, saw blade depaneling delivered both speed and consistency—because the board design supported it.

🧠 How to decide in practice

Choose saw blade depaneling if:

- Boards are rectangular with straight edges

- Components are not extremely close to the cut line

- High throughput is a priority

- Process stability has been validated

Choose routing if:

- PCB shapes are irregular

- Stress-sensitive components are present

- Yield and long-term reliability matter more than takt time

Speed should support quality, not replace it.

🛠️ A balanced production strategy

Many advanced factories don’t choose one method. They:

- Use saw blade depaneling for standardized, high-volume products

- Keep routing for complex or high-risk PCBAs

This hybrid approach often delivers the best overall efficiency.

🌐 Why Choose Seprays Group?

Seprays Group develops both saw blades and routing depaneling solutions with a focus on:

- Controlled mechanical stress

- Stable cutting performance

- Industrial durability for continuous operation

Rather than pushing a single method, we help manufacturers match the right depaneling technology to their actual PCB design and production goals.

If you are evaluating saw blade depaneling for speed improvement—or comparing it with routing—please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)