This is one of the most common questions engineers ask when evaluating depaneling methods for high-volume SMT production. The short answer is: it depends on how the process is designed, not just the cutting method itself.

Saw blade depaneling can be fast and consistent, but it also introduces mechanical forces that must be controlled carefully. In this article, we share real-world observations from production lines, discuss where risks come from, and explain when saw blade depaneling is safe—and when it isn’t.

⚙️ Where Component Damage Concerns Come From

Component damage rarely comes from the saw blade alone. It usually comes from stress transfer.

During depaneling, stress can be introduced through:

- Board bending during cutting

- Inconsistent support under the PCB

- Blade entry and exit shock

- Poor alignment of the V-groove

When components are close to the cut line, even small mechanical forces can affect solder joints, MLCCs, or fine-pitch devices.

The concern isn’t theoretical. Many SMT engineers have seen latent failures appear weeks later, traced back to depaneling stress rather than assembly defects.

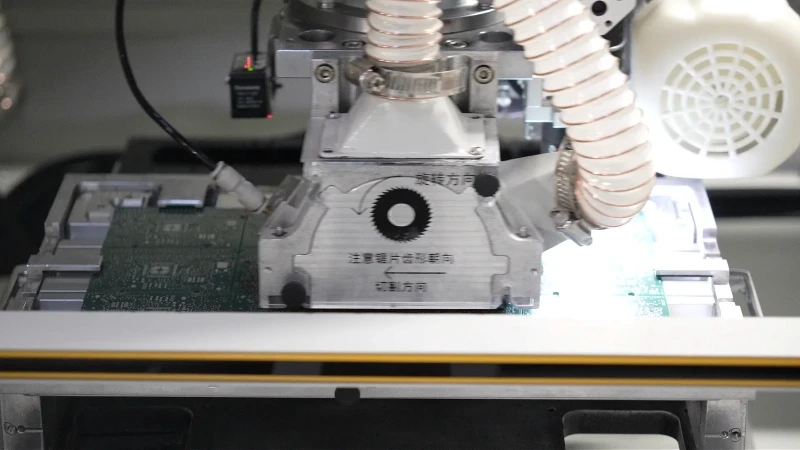

🔍 What Actually Happens During Saw Blade Depaneling

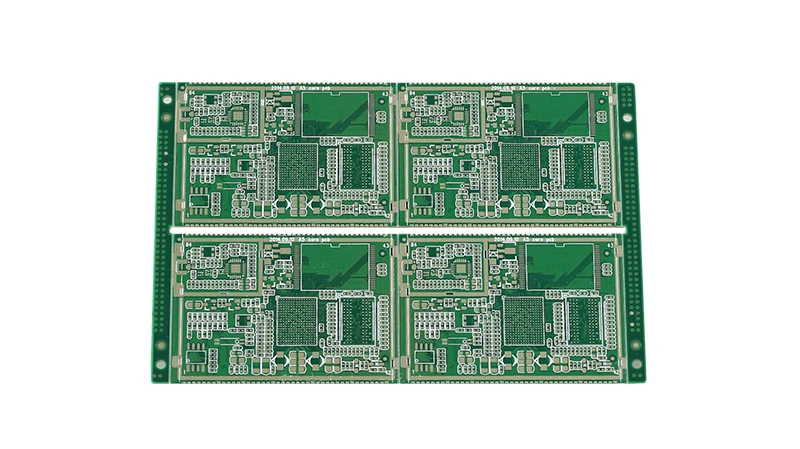

Saw blade depaneling works by cutting along a pre-designed V-groove. This allows continuous, high-speed separation, making it popular for mass production.

However, the blade applies:

- Vertical pressure

- Lateral shear force

- Local vibration at the cutting edge

If the PCB is thin or densely populated, that force has nowhere to go—except into the components.

This is why some lines report zero issues, while others experience cracked capacitors or micro-fractures.

⚠️ Typical Pain Points Engineers Report

From field feedback, the most common issues are:

- MLCC cracking near board edges

- Solder joint fatigue after thermal cycling

- Micro-cracks not visible in AOI

- Higher failure rates in drop or vibration tests

These problems are especially common in:

- Thin PCBs (<1.2 mm)

- High-density consumer electronics

- Automotive and industrial boards with edge-mounted components

The key question becomes not “Is saw blade depaneling bad?” but “Is it suitable for this board?”

💰 Cost vs. Risk: Why Saw Blade Is Still Widely Used

Saw blade depaneling remains popular because it offers:

- High throughput

- Stable cut quality on uniform panels

- Lower operating cost compared to routing or laser

- Simple maintenance and long blade life

For high-volume products with:

- Components kept away from the V-cut line

- Rigid PCB structures

- Well-controlled panel design

…the risk is often acceptable, and the cost advantage is real.

Problems arise when the saw blade depaneling is applied outside its comfort zone.

🧪 A Production Case from Seprays Experience

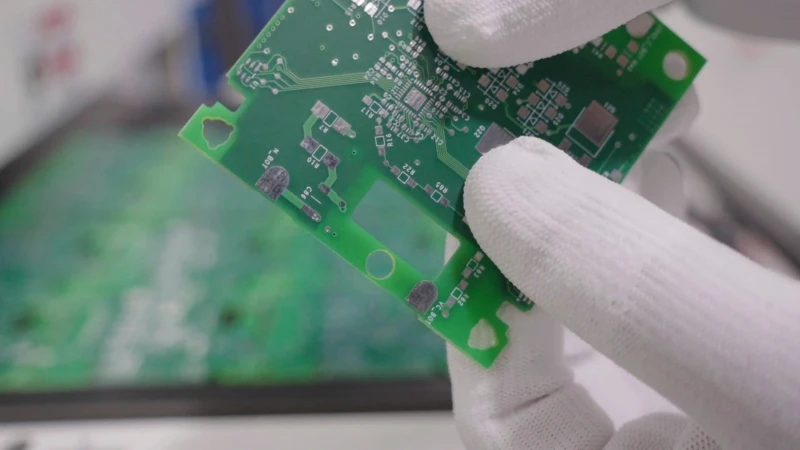

In one consumer electronics project supported by Seprays, the customer initially used saw blade depaneling for a compact control board.

Early tests passed AOI and ICT.

However, after reliability testing, MLCC cracks appeared near the board edge.

Instead of immediately changing the depaneling method, the team adjusted:

- PCB support structure

- Blade speed and feed rate

- Component keep-out distance

The failure rate dropped significantly. In the end, saw blade depaneling remained in use—but with tighter process control and design changes.

The lesson was clear: process optimization mattered more than switching technology.

🛠️ How to Reduce Component Damage with Saw Blade Depaneling

If saw blade depaneling is required, risk can be reduced by:

- Increasing component-to-edge distance

- Using rigid support under the cutting line

- Optimizing blade sharpness and speed

- Avoiding sudden blade entry and exit

- Validating with strain or micro-crack testing

In some cases, switching to router depaneling or laser depaneling is still the better choice—especially for fragile or high-value assemblies.

🤔 So, Does Saw Blade Depaneling Damage Components?

The honest answer: it can—but it doesn’t have to.

Saw blade depaneling is not inherently destructive.

It becomes risky when PCB design, component placement, and process parameters are misaligned.

For the right product, it is efficient and reliable.

For the wrong product, it can quietly introduce long-term reliability issues.

That’s why many SMT teams now evaluate depaneling as part of the design and reliability discussion, not as an afterthought.

🔧 Choosing the Right Depaneling Strategy

Before deciding, ask:

- How close are components to the cut line?

- How thin is the PCB?

- Is long-term reliability more important than cycle time?

- What failure modes are acceptable?

Answering these questions early often prevents expensive corrections later.

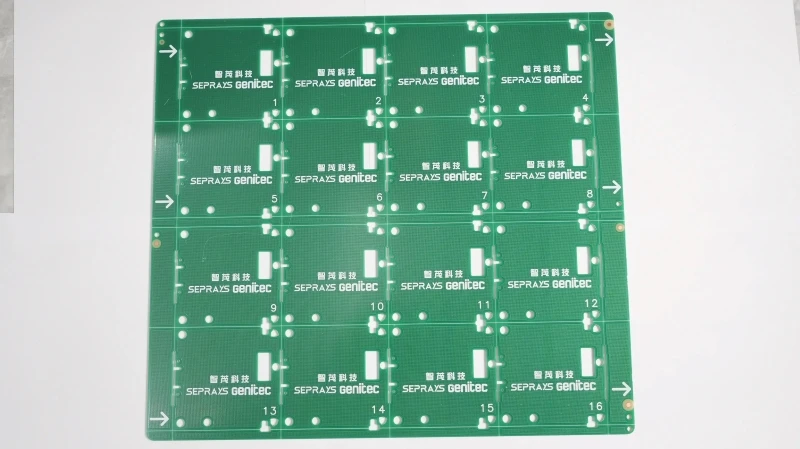

⭐ Why Choose Seprays Group?

Seprays Group works closely with SMT manufacturers to evaluate real depaneling risks, not just machine specifications. With experience across saw blades, routers, and laser depaneling solutions, Seprays focuses on matching the process to the product—not forcing the product to fit the process.

If you’re unsure whether saw blade depaneling is right for your PCB design, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)