什么是工作原则的激光分板?

工作原则的激光分板涉及使用高能激光束的精确穿过连接的标签或道路的一种PCB(印刷电路板的)小组,分离各个板没有机械触点。 激光来源,例如一个CO2或激光中,产生一个焦光束引导到的PCB的材料通过光学系统。

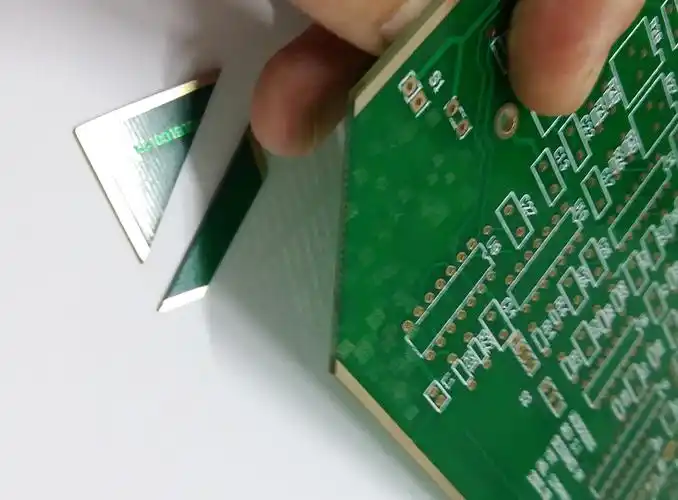

When the laser interacts with the material, its energy is absorbed, causing localized heating and vaporization (ablation) along the programmed cutting path. This process is controlled by software that guides the laser head with high precision, enabling the creation of complex shapes and fine details to be cut cleanly. Since laser depaneling is a non-contact method, it eliminates mechanical stress, reduces the risk of damage to sensitive components, and produces minimal debris, making it ideal for high-density and delicate PCB designs.

什么类型的激光器被用于激光分板?

CO2激光器:

- Best for cutting non-metal materials, such as FR-4 (a common PCB material).

- Fast and cost-effective, but can’t cut metals well.

紫外线激光器:

- Great for high-precision cutting, especially for flexible PCBs or materials with copper.

- Very accurate with minimal heat damage, but slower and more expensive.

绿色激光器:

- Used for specific materials like flexible circuits.

- Offers good precision but is less common and more costly.

纤维激光器:

- Used for cutting metal-based PCBs.

- Efficient for metals but not suitable for non-metal materials.

飞秒激光器:

- Ultra-high precision with almost no heat damage.

- Ideal for delicate materials, but very expensive and slow.

皮秒激光器:

- Similar to femtosecond lasers but slightly less precise.

- Still high-cost and used for advanced applications.

激发物激光器:

- Used for very precise cutting of special materials.

- High resolution but expensive and complex to maintain.

之间有什么区别的CO2激光和紫外线激光器分板应用程序?

之间的区别是什么激光、分割和传统机械分板?

Seprays'激光PCB、分割的解决方案

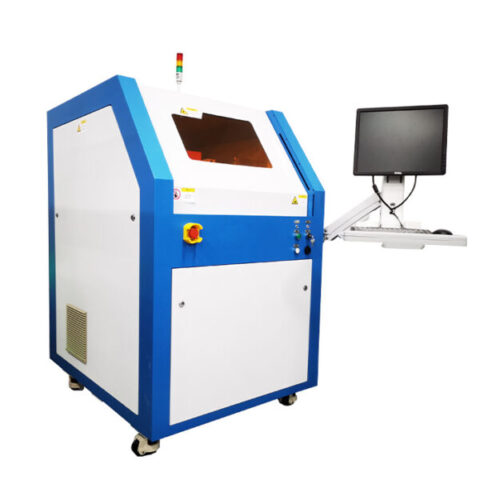

ZAM310 PCB/FPC激光分板机

SEPRAYS’ZAM310 PCB/FPC Laser cutting machines ensure that no stress is imparted to nearby components, even when the cutting path is very close to them. To further minimize thermal impact, lasers are carefully selected based on thermal requirements, and their processing parameters are precisely matched to optimize performance.

ZAM320 PCB/FPC激光切割机

SEPRAYS’ZAM320 PCB/FPC Laser Cutting Machine has a compact design and can save factory space. A variety of nanosecond, picosecond UV, and green lasers are available to meet various processing needs.

结论

激光分板 is a major improvement in PCB manufacturing, offering precise, clean cuts without damaging sensitive components. By understanding how it works and the types of lasers used, manufacturers can choose the best method for their needs. As electronics continue to get smaller and more complex, laser depaneling will become even more important. With its ability to cut delicate designs without stress or debris, laser depaneling is shaping the future of electronics production.

.png)