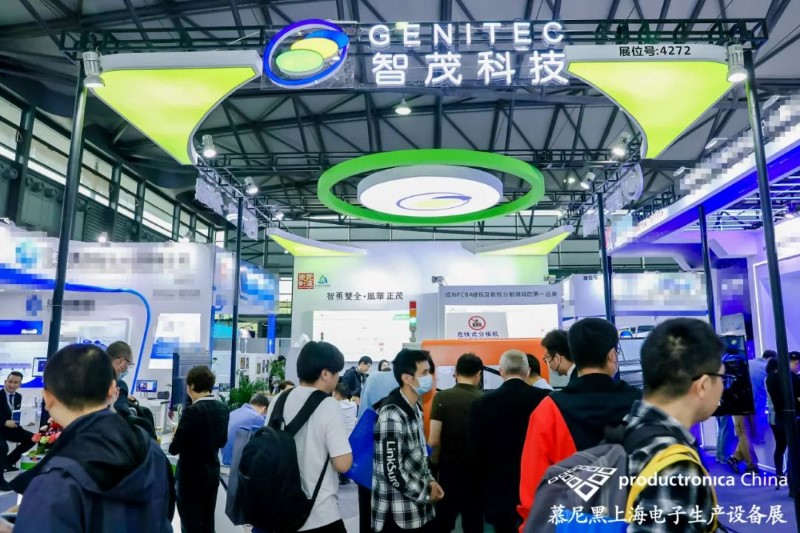

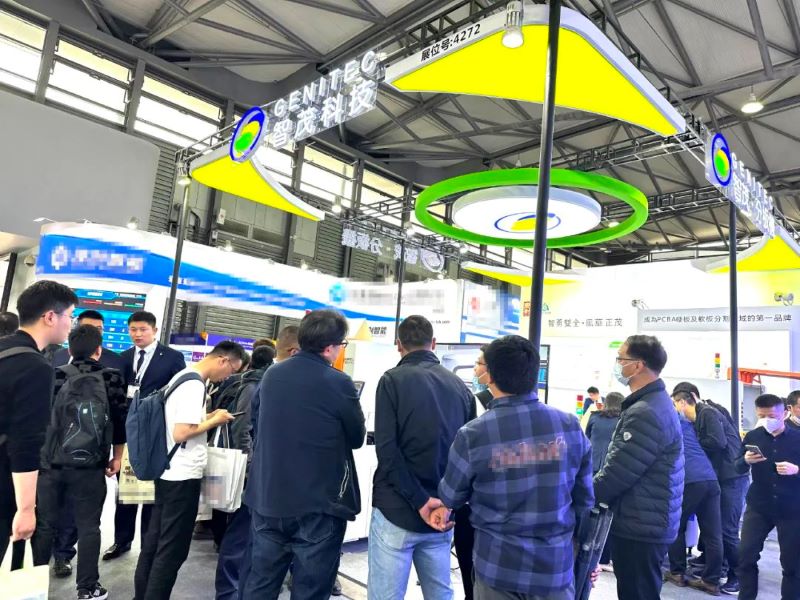

Three years after the epidemic, the number of domestic and overseas merchants to come far exceeded expectations, and the scene was crowded with extraordinary pageantry.

最新的depanel技术闪耀在展览

Genitec showcased the offline bottom cut PCB Router GAM386 at booth 4272, and their on-site technical explanations attracted numerous customers to visit and engage in negotiations.

Although the brands of the board industry are numerous, the problems of the board are still emerging, and problems such as manual problems, equipment footprint, accuracy, dust, and cutting methods have brought great troubles to the depanel process.

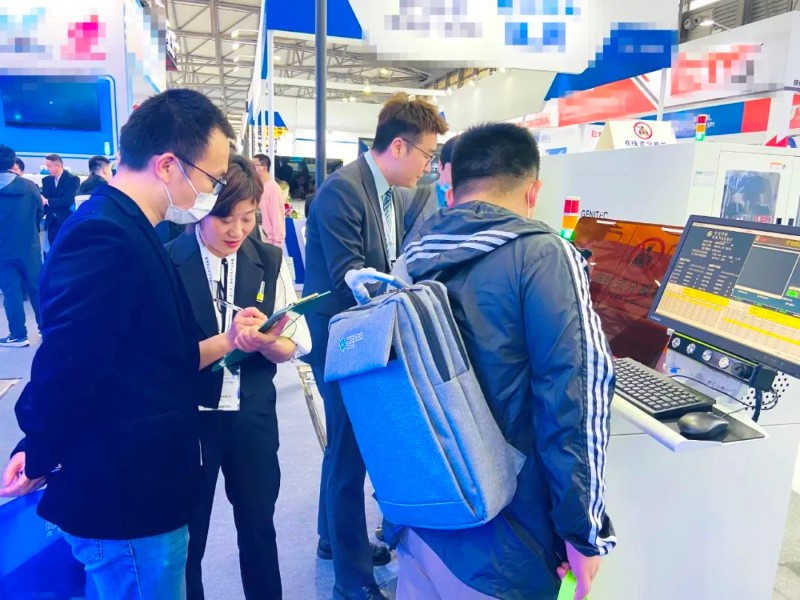

Genitec this time exhibition -GAM386, completely designed for the bottom cutting industry operating pain points. Dual working tables minimize PCB placement waiting time and boost productivity. The bottom cutting design suits PCBs with taller upper components and provides IO contact for robotic arms. By preventing board access during operation, the system greatly enhances safety, helping enterprises improve efficiency and reduce costs.

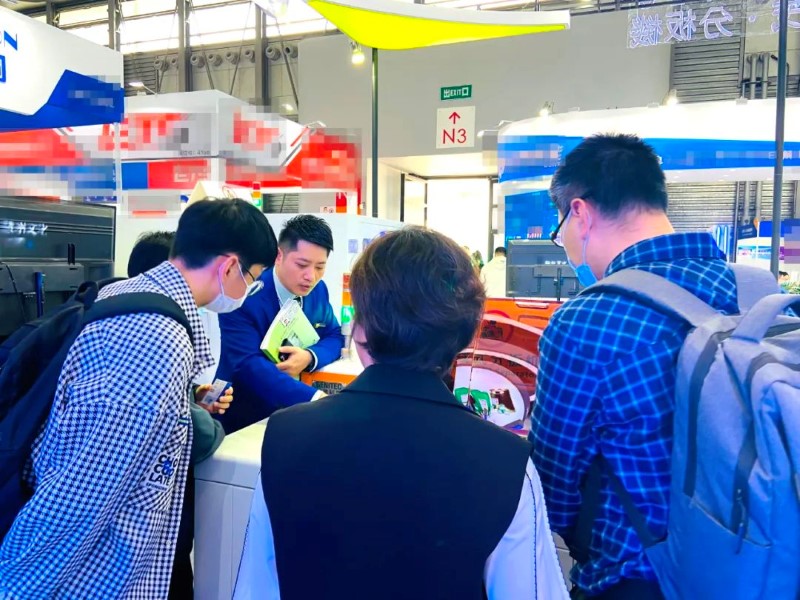

展览期间,Genitec内部技术顾问解释的设备系列的、分割+检测+自动装卸机和展览。

During the three-day exhibition, Genitec consultants actively demonstrated the manufacturing processes of the Router inline + offline bottom cut machine, laser depaneling machine, automatic V-saw cutting machine, punching machine, and other equipment. They showcased powerful software control technologies and provided detailed answers to various deployment challenges. Many customers expressed strong interest and a willingness to learn more.

With innovative machine equipment, professional R&D, sales team, and a wealth of landing projects, Genitec once again harvests the favor of new and old customers.

荣誉前进,不要忘了原来的心脏。 在未来,Genitec将继续秉持智慧,在深入发展的更好质量的PCB、分割的整个线设备,成千上万的SMT企业降低成本和效率、完全自动操作、安全生产带来的好消息。

.png)