Best PCB Depaneling Machine selection is often treated as a purchasing task, but in reality, it is an engineering decision that affects product quality, yield stability, and long-term operating cost. Based on feedback from global SMT lines, many buyers encounter similar mistakes—not due to lack of effort, but due to incomplete evaluation criteria.

⚠️ Mistake 1: Focusing on Cutting Speed Instead of Board Stress

One of the most common misconceptions is equating higher speed with higher productivity. While cycle time matters, engineers frequently report that excessive cutting force or vibration leads to hidden stress on components and solder joints.

In high-density or thin PCB designs, stress-related microcracks may only appear after thermal cycling or field operation. The lesson shared by experienced SMT managers is clear: controlled force and stability often outweigh raw speed.

🧩 Mistake 2: Underestimating Long-Term Durability

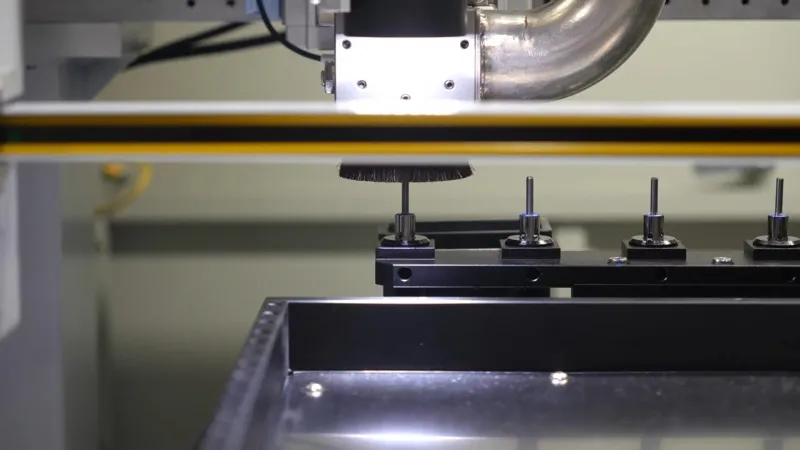

Initial performance during factory acceptance tests can be misleading. Buyers sometimes overlook spindle lifespan, mechanical rigidity, or dust management design. Over time, wear-related drift in accuracy leads to inconsistent results between shifts.

From an industrial quality perspective, durability is not about how a machine performs on day one—but how predictably it performs after thousands of operating hours.

💰 Mistake 3: Incomplete Cost Analysis

Purchase price is only one component of total cost. Hidden costs often emerge later:

- Tool wear and frequent replacement

- Increased maintenance downtime

- Additional inspection or rework labor

- Secondary cleaning processes

Several SMT lines have shared that a lower-cost machine resulted in higher per-board cost within the first year due to yield loss and unplanned maintenance.

🏭 Case Example: Mid-Volume Consumer Electronics Line

A European EMS provider initially selected a depaneling system based on price and quoted throughput. Within six months, they observed rising defect rates on fine-pitch components. After switching to a more stable solution with better motion control, defect rates normalized—even though nominal speed was lower.

The takeaway: process stability directly influences real productivity.

🛠️ Mistake 4: Ignoring Process Compatibility

Not all depaneling machines adapt well to mixed production. Buyers sometimes fail to consider:

- PCB thickness variation

- Panel design changes

- Future product roadmaps

Machines optimized for a single board type may struggle when production flexibility becomes necessary. Engineers increasingly recommend selecting systems that allow parameter tuning rather than fixed cutting profiles.

📊 Solution-Oriented Selection Approach

Experienced buyers suggest a different evaluation mindset:

- Validate stress control, not just speed

- Request long-run accuracy data

- Analyze total cost per board, not machine price

- Involve process engineers early in selection

This approach aligns depaneling with quality goals rather than treating it as a standalone step.

💬 An Open Question for the Industry

Is the “best” depaneling machine universal? Most engineers agree it is not. The best choice depends on board design, reliability requirements, and production strategy. Sharing real-world lessons helps avoid repeating costly mistakes.

Why Choose Seprays Group?

Seprays Group focuses on supporting manufacturers with depaneling solutions designed around industrial quality, durability, and long-term process stability. Our approach emphasizes real production conditions rather than short-term benchmarks.

If you are evaluating depaneling systems or reassessing an existing setup, please feel free to contact us for technical discussion and experience sharing.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)