Dual Solutions from Seprays – Online and Offline Milling Cutter Machines

If you’re in PCBA production, you know the struggle.

Tall components can be a nightmare during depaneling.

Traditional machines either can’t reach or end up crashing into components, causing stress damage. Watching your precision boards stuck at this stage is frustrating, inefficient, and risky.

But don’t worry — Seprays has the answer.

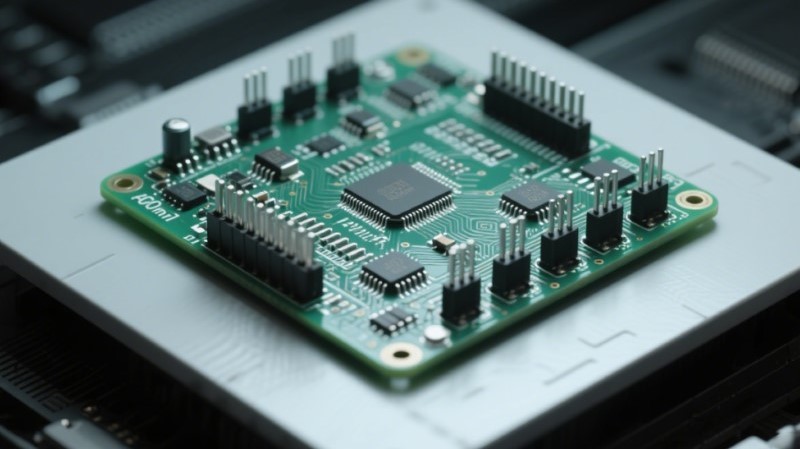

We offer dual depaneling solutions specifically designed for high-component PCBs (≤75mm). Choose between the online GAM386AT and the offline GAM386 models.

💡 Key Innovation: Bottom-Up Milling Design

Our cutter approaches the board from underneath.

This smart design avoids collision with tall components on top.

Perfect for mobile modules, automotive electronics, and high-end communication boards.

🔧 Online Depaneling – GAM386AT

Seamlessly integrates with SMT production lines

- Inline Integration: Connects directly to upstream and downstream SMT machines (e.g., pick-and-place, AOI, AGV). Enables fully automated PCB transfer.

- Dual Workstations + Movable Cover: One side loads/unloads while the other cuts. This reduces idle time and maximizes efficiency.

- Track/Belt Feeding: Supports conveyor automation and custom output handling (e.g, tray placement).

- High Integration: Easily connects with MES for traceability and remote monitoring.

✅ Best for:

- High-volume, continuous production lines

- Factories seeking top OEE and reduced lab costs, or

- Fully automated, smart SMT lines

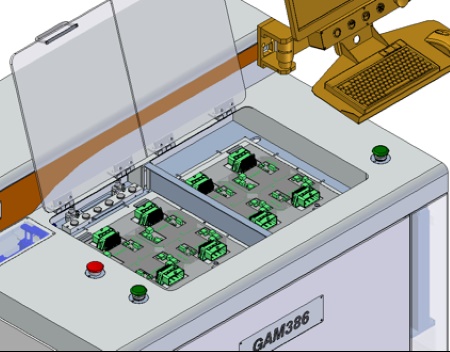

🧩 Offline Depaneling – GAM386

Flexible and independent precision cutting

- Stand-Alone Advantage: No need to connect to a production line. Easy deployment and high adaptability.

- User-Friendly Operation: Supports manual or semi-automatic loading. Quick to switch lines and adjust settings.

- Standard Safety Features: Includes safety light curtains for operator protection.

- Full Capability: Offers the same bottom-up design, dust control, stress relief, ESD protection, and high-precision cutting.

✅ Best for:

- Small batch, multi-variety production

- R&D, prototyping, labs, and repair stations

- Facilities are not yet ready for full automation

- Cost-sensitive early-stage users

🎯 Why Seprays Excels at High-Component Depaneling

1. 🎯 Precision Matters (Both Models)

- Solid Z-axis frame made of cast aluminum

- Imported German high-precision spindle + pneumatic tool changer

- 15x magnification CCD visual system

- Optional high-accuracy fixtures ensure perfect cutting alignment

2. 🧹 Dust-Free Cutting (Both Models)

- Patented floating brush adapts during cutting

- Powerful HEPA dust collector with ≥29m/s suction

- Real-time negative pressure monitoring to guarantee results

3. 🧘♂️ Stress Control (Both Models)

- Floating brush cushions Z-axis impact

- Elastic clamping reduces vibrations

- Gentle segmented suction placement

- Stable 80,000 RPM German spindle for smooth operation

4. ⚡ Full ESD Protection (Both Models)

- Anti-static spindle, brush, suction tube, and conveyor

- Industrial-grade ESD eliminator discharges 1000V → 100V in 1 second

- Safe circuit monitoring system

5. ⚙️ Efficiency That Doesn’t Compromise

GAM386AT (Online)

- Dual-station setup boosts productivity

- Custom software delivers 30%+ more throughput than the industry average

- 99% yield rate, barcode-based quick changeover

GAM386 (Offline)

- Fast setup and line change

- Ideal for agile production environments

🔍 Which One Should You Choose?

Choose GAM386AT (Online) if:

- You have or plan to build a fully automated SMT line

- Your product is high-volume with stable models

- Your goal is max productivity with minimal human input

- You need real-time monitoring and MES integration

Choose GAM386 (Offline) if:

- You run small batch, frequent changeover production

- You work in R&D, prototyping, or repair stations

- You don’t require full-line automation

- You prioritize flexibility and lower initial investment

🎉 Say Goodbye to High-Component Depaneling Headaches

Whether you need inline automation or standalone precision,

Separate bottom-up depaneling machines offer a safe, accurate, and efficient solution for PCBs with components up to 75mm tall.

- Online Model: Built for automated lines. The king of efficiency.

- Offline Model: Flexible and adaptable. Ready for any challenge.

Choose Seprays — Your Expert Partner in PCB Depaneling

📩 Contact us now for a free consultation and the best-fit solution for your production line!

.png)