In PCB manufacturing, burrs—those tiny, unwanted metal or fiberglass edges—are a common issue during depaneling. They may seem minor, but they can lead to serious quality concerns such as electrical shorts, poor solderability, and reduced product reliability. This article explores how to eliminate burrs in the PCB depaneling process, comparing traditional and advanced methods, and sharing insights from real factory applications.

⚙️ Understanding the Root Cause of Burrs

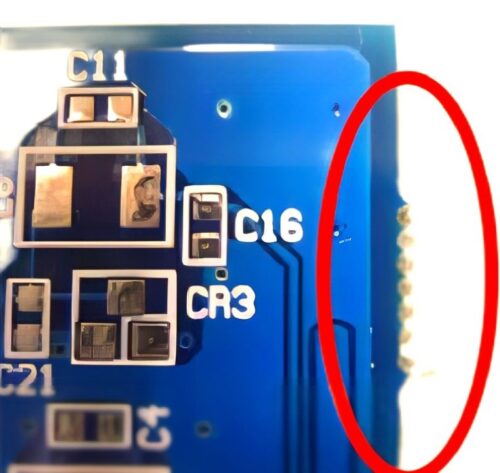

Burrs typically form when the cutting stress between the tool and PCB substrate exceeds material tolerance.

Key causes include:

- Dull blades or worn router bits that tear rather than cut cleanly.

- Incorrect cutting parameters—speed, feed rate, or depth.

- Improper fixturing is causing vibration during depaneling.

- Material type, especially FR4 and composite boards, which are prone to chipping and micro-fractures.

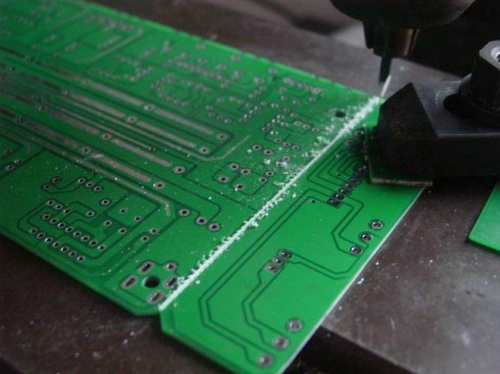

In manual or saw-blade depaneling, mechanical contact is the main culprit. Operators apply force inconsistently, and even small deviations in angle or speed can create burr edges that require extra sanding or cleaning.

🔍 Pain Points in Traditional Depaneling

Before moving to advanced solutions, it’s important to acknowledge what manufacturers face when using manual or semi-automatic methods:

- Inconsistent Quality – Burr formation varies by operator skill and cutting condition, leading to high defect rates.

- Rework Costs – Manual deburring adds labor time and risk of secondary damage.

- 工具戴上 – Saw blades and router bits degrade quickly, causing unpredictable burr patterns.

- Production Downtime – Frequent tool replacement and cleanup slow down line efficiency.

- Surface Contamination – Fiberglass particles and dust can affect soldering and component reliability.

These issues compound into significant hidden costs and quality instability over time.

💡 The Cost of Burrs in PCB Production

Let’s break down the real-world financial impact of burrs:

- Labor Costs: Each manual deburring step adds 5–10 minutes per board panel. Over 10,000 boards, which can mean hundreds of labor hours lost.

- Tool Replacement: Router bits and saw blades need frequent changes, adding both material and maintenance costs.

- Yield Loss: Even minor burrs can cause defects in solder joints or misalignment in downstream processes.

- Customer Complaints: Burr-related short circuits or mechanical interference can lead to warranty claims and reputation damage.

Thus, eliminating burrs is not only a quality improvement—it’s a profit protection strategy.

🚀 Advanced Solutions to Eliminate Burrs

Today’s leading manufacturers are shifting toward non-contact or precision-controlled depaneling technologies. Below are proven solutions that significantly reduce or eliminate burr formation:

1. 激光分板

Laser depaneling is a contact-free cutting process that uses high-energy beams to vaporize material instead of cutting it mechanically.

✅ Zero mechanical stress

✅ Smooth, burr-free edges

✅ Ideal for flexible PCBs and ultra-thin substrates

2. High-Speed Router Depaneling

Modern router depaneling machines with CCD vision positioning and automatic tool calibration maintain consistent cutting paths and depth.

✅ Precise spindle control reduces friction

✅ Software-optimized cutting paths minimize tool wear

✅ Integrated dust extraction keeps surfaces clean

3. Optimized Fixture Design

Stable fixture systems, such as vacuum clamps or automatic tray handling, reduce vibration during routing. This prevents micro-cracks and edge chipping.

4. Hybrid Automation Systems

Factories now integrate depaneling with automated visual inspection (AOI) to detect burrs in real-time, ensuring continuous quality feedback.

🧰 Case Study: Burr-Free Production in a German Electronics Factory

A mid-sized electronics manufacturer in Germany struggled with edge burrs on high-density automotive PCBs. After switching from manual saw depaneling to a SEPRAYS automated router system, they reported:

- Zero visible burrs after 30,000 panels

- 35% reduction in tool costs due to optimized cutting parameters

- 20% increase in throughput thanks to integrated tray loading

- Improved solder reliability, reducing post-assembly rework

This transformation was achieved without changing PCB materials—only through process innovation and better equipment control.

🔧 Practical Tips to Reduce Burrs

Even if you haven’t yet adopted a fully automated solution, here are practical steps that can help reduce burrs in your current process:

- Use sharp, high-quality cutting tools and replace them regularly.

- Adjust spindle speed and feed rate to find the ideal balance for your PCB material.

- Ensure stable fixturing to eliminate vibration and flex.

- Clean dust and debris between panels to prevent re-deposition.

- Inspect regularly under magnification to detect burrs early, before large-scale production.

🌍 Moving Toward a Burr-Free Future

As PCB designs become more compact and complex, edge quality will continue to be a top concern. Transitioning from manual or semi-automated depaneling to intelligent, precision-controlled systems is the path forward for manufacturers seeking reliability, speed, and long-term cost efficiency.

⭐ Why Choose Seprays Group?

SEPRAYS Group brings over 32 years of expertise in PCB and FPC depaneling innovation. Our product range includes routers, lasers, V-cut, and punching machines, all integrated with intelligent handling systems for full automation. We focus on delivering burr-free, stress-free cutting performance that enhances production efficiency and long-term yield.

If you are looking to eliminate burrs, reduce rework, and improve your PCB quality, contact us today — SEPRAYS will help you find the right solution for your production line.

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)