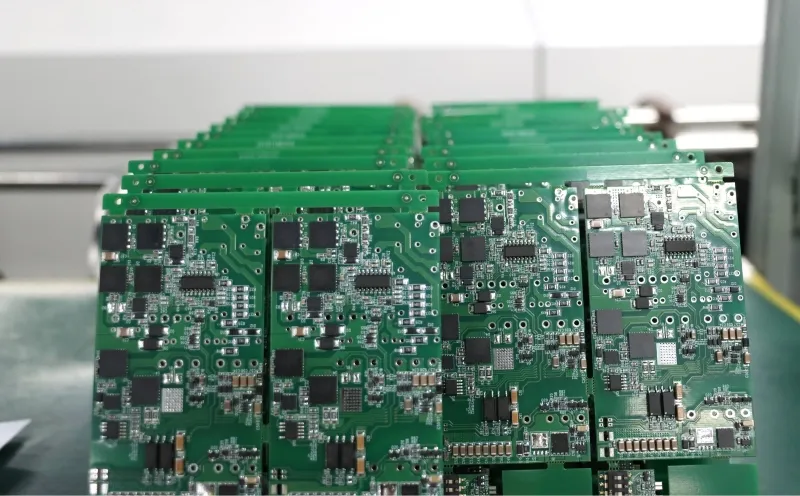

PCB Depaneling Stress Reduction Techniques have become a crucial topic in high-density PCBA production. As boards become more compact, populated with sensitive components, and multi-layered, mechanical stress during depaneling can lead to micro-cracks, solder joint fatigue, and long-term reliability issues. This article presents field-tested approaches, practical fixes, and engineering insights from global SMT lines.

⚙️ Understanding Stress in High-Density PCBA Depaneling

High-density PCBA presents unique stress challenges:

- Edge-mounted connectors and fine-pitch components are sensitive to mechanical forces

- Multi-layer boards amplify vibration transfer during routing or V-cut separation

- Thin PCBs can flex, transmitting stress to critical components

Engineers report that even minor deviations in tool alignment or panel support can trigger latent defects, which often remain hidden until thermal cycling or vibration testing.

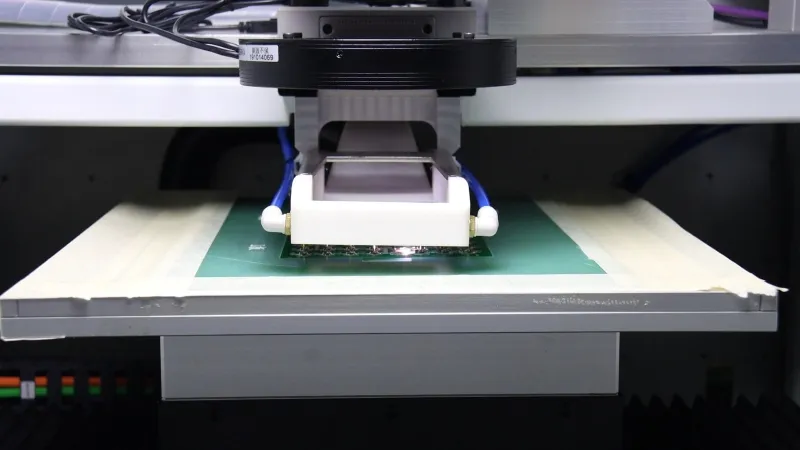

🧩 Technique 1: Optimized Router Parameters

Routing remains a widely used depaneling method for dense boards. Key stress-reduction strategies include:

- Adjust spindle speed and feed rate according to board thickness and copper density

- Use high-quality, sharp bits to minimize cutting force

- Implement anti-vibration fixtures and vacuum support for thin or flexible panels

Case insight: A European automotive EMS line reduced micro-crack rates by 30% by fine-tuning router speed and adding full-panel support.

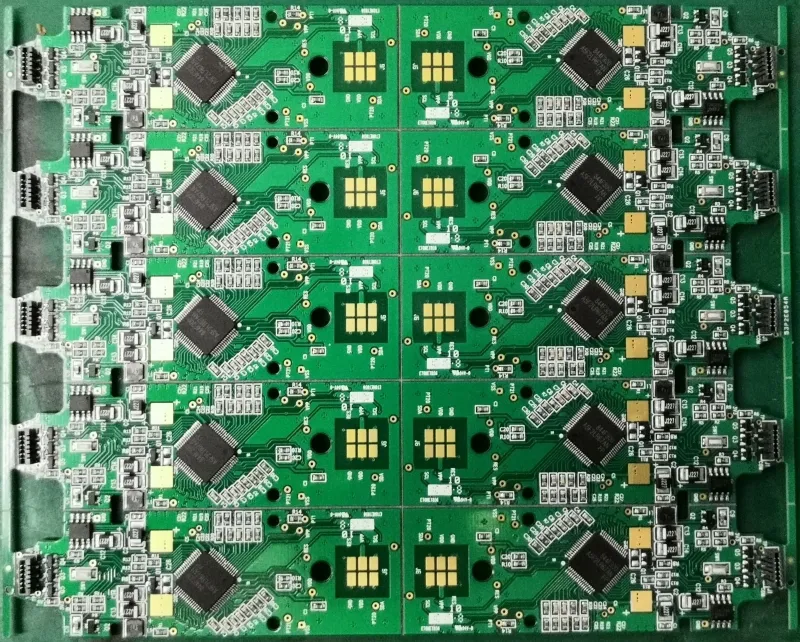

🪚 Technique 2: V-Cut and Blade Handling Adjustments

V-cut and blade separation remain common in high-volume production. Best practices for stress control:

- Ensure uniform scoring depth across the panel

- Maintain blade sharpness and proper alignment

- Control the separation speed to prevent sudden snapping forces

- Provide sufficient clearance between edge-mounted components and score lines

Properly tuned V-cut processes can maintain high throughput without compromising reliability.

🔦 Technique 3: Laser Depaneling for Minimal Contact

Laser depaneling eliminates direct mechanical stress, ideal for sensitive or ultra-thin boards. Practical considerations include:

- Optimize laser power and focus to prevent localized heat damage

- Integrate inline inspection to detect micro-ablation effects

- Ensure proper fume extraction to maintain a clean cutting environment

While initial costs are higher, stress reduction and consistency often justify investment for high-value applications.

📉 Cost Implications: Hidden Expenses of Stress

Stress-induced defects can carry hidden costs beyond equipment purchase:

- Rework and scrap due to micro-cracks

- Extended functional testing and quality verification

- Field returns or warranty claims

Experienced engineers emphasize evaluating depaneling investment based on total cost per board, considering both yield and reliability improvements.

🏭 Case Example: Industrial Control PCBA

An industrial control PCB line experienced intermittent solder joint failures during vibration testing. Root-cause analysis identified mechanical stress during router depaneling as the culprit. After implementing fixture adjustments, optimized routing parameters, and supplemental V-cut pre-scores on flexible areas, defect rates dropped by over 40%, demonstrating the value of combining multiple stress-reduction techniques.

🛠️ Practical Guidelines for Engineers

- Evaluate PCB design for stress-sensitive regions before depaneling

- Match the depaneling method to the component density and material properties

- Use real-time monitoring of spindle vibration, tool wear, and panel support

- Validate stress-reduction effectiveness through reliability testing, not just visual inspection

These guidelines ensure high-density PCBAs meet industrial durability and quality standards.

💬 Why Choose Seprays Group?

Seprays Group specializes in industrial-grade depaneling solutions for high-density PCBA, focusing on durability, stress reduction, and consistent production performance. Our experience helps manufacturers optimize routing, V-cut, and laser depaneling techniques for real-world SMT environments.

If you want to discuss stress reduction strategies or evaluate tailored depaneling solutions, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)