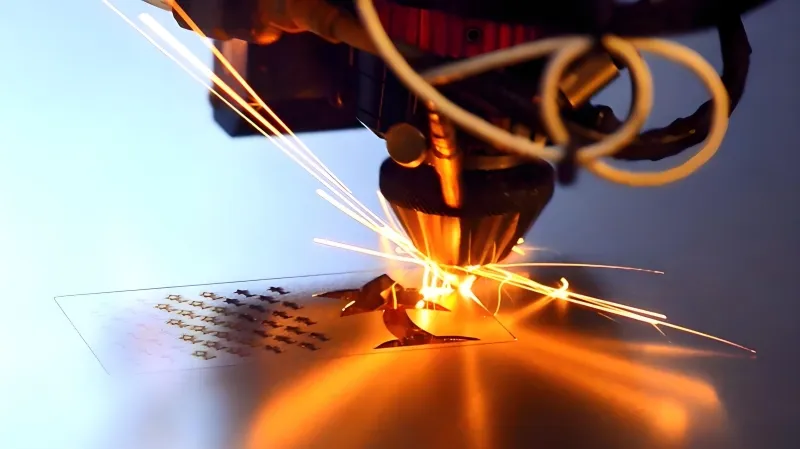

PCB Milling Machine performance is a frequent discussion point among manufacturers aiming to reduce burrs, edge chipping, and downstream defects. Across Europe—especially Germany and France—engineers tend to favor high-precision, low-variance machining. From spindle behavior to bit selection, fixture stability, feed rates, and routing paths, each factor affects how cleanly a PCB can be milled.

This article summarizes real factory insights, case studies, and practical lessons gathered from SMT lines worldwide, with an emphasis on EU-style industrial standards: durability, consistent quality, and engineering logic over marketing.

⭐ H1 — Why Burrs and Edge Chipping Occur More Often Than Expected

Even with modern PCB milling machines, manufacturers still report:

- Rough edges near FR4 glass fibers

- Micro-cracks caused by bit vibration

- Excess burrs during high-speed routing

- Localized delamination on multilayer boards

Key observation from SMT lines:

Most issues are not caused by the PCB material itself, but by tooling conditions and routing dynamics.

In one German automotive electronics factory, over 50% of milling-edge defects were traced back to incorrect spindle torque compensation rather than the router bit.

⚙️ H2 — Router Bit Material and Geometry: The Foundation of a Clean Cut

Tooling quality is a major differentiator.

✔ What engineers have learned:

- Single-flute bits offer cleaner cuts on thin FR4 and FPC stiffeners.

- Two-flute bits provide lower burrs but require higher spindle stability.

- Diamond-coated bits reduce wear but demand precise routing paths.

- Shorter bits (short flute length) significantly reduce vibration amplitudes.

Case example:

A French telecom PCB factory cut burr size by 32% simply by switching from a 1.5-mm two-flute bit to a 1.2-mm diamond-coated short-flute bit.

🔧 H3 — How Spindle Speed and Feed Rate Shape Cutting Quality

Spindle behavior is often underestimated.

European factories typically operate milling at 45,000–60,000 RPM for tight tolerances.

Best-practice insights:

- High spindle speed + low feed rate = clean cut but higher tool wear.

- Too slow a spindle = higher burr formation due to fiber pull-out.

- Too fast a feed = edge chipping due to mechanical shock.

Field observation:

A Spanish EMS plant reduced chipping by 27% after adjusting the cutting speed to match the bit diameter:

Formula engineers often use:

Surface speed (m/min) = π × tool diameter × spindle speed

This ensures the bit engages material in a consistent cutting pattern rather than scraping.

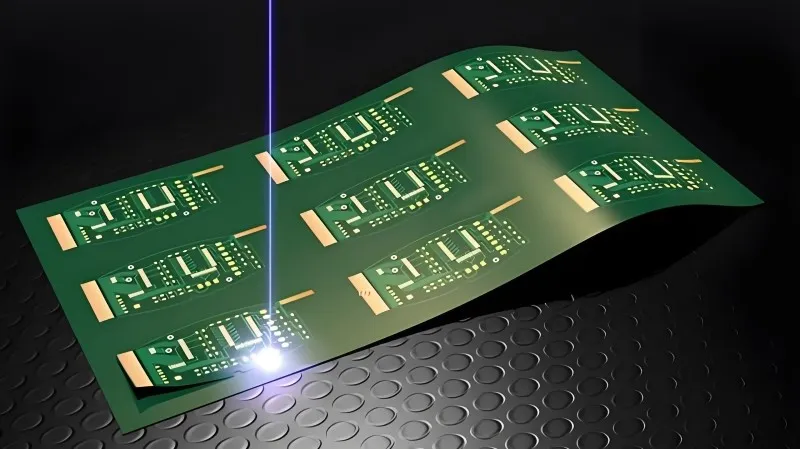

📏 H4 — Routing Path Strategy: The Hidden Influence on Burr Formation

Routing order affects vibration loads and thermal accumulation.

Proven routing strategies:

✔ Route long edges first to stabilize panel stress

✔ Leave tabs or bridges until the last step

✔ Use climb milling instead of conventional milling

✔ Add entry/exit pads to avoid starting cuts directly on copper traces

A Polish industrial electronics producer reported smoother edges after implementing pre-routing (1-mm shallow pass before the final cut).

🛠️ H5 — Fixture Design and Panel Flatness: The Silent Quality Killers

Uneven support surfaces create milling inconsistencies and unpredictable chipping.

Key lessons:

- Vacuum tables work well but require fine filtration.

- Mechanical clamps introduce micro-stress.

- Hybrid systems (vacuum + soft clamps) offer the best stability.

- Avoid routing within 10 mm of a PCB warpage area.

A Dutch manufacturer reduced burr complaints by 40% after switching to adjustable pressure fixture pads.

💬 H6 — Cost Analysis: Does Reducing Burrs Mean Higher Cost?

Not necessarily.

Real cost-saving trends:

- Better bits = longer tool life (reduces bit replacement cost 20–30%).

- Optimized feed parameters = fewer scrapped panels.

- Cleaner edges = less manual rework time.

- Stable fixtures = fewer spindle failures.

Total cost savings per month (example from a German plant):

- Labor savings: €2,400

- Bit consumption reduction: €1,200

- Scrap reduction: €1,600

Total: €5,200 saved per line/month

🧩 H7 — Practical Checklist for Manufacturers

Before modifying your PCB milling strategy, verify:

| Key Factor | What to Check |

|---|---|

| Bit Wear | Inspect for micro-cracks and diameter loss |

| Spindle Stability | Torque balance + RPM drift |

| Routing Order | Long edges first, exit pads applied |

| PCB Material | Tg, fiber density, copper thickness |

| Fixture System | Flatness, vacuum leakage, pressure marks |

This checklist aligns with typical German DIN and French industrial quality frameworks, emphasizing stability and repeatability.

🌟 Why Choose Seprays Group?

Seprays provides industrial-grade PCB milling and depaneling solutions built around:

- High-precision spindles

- Long-life tooling compatibility

- EU-level durability & machine safety

- Engineering-driven optimization

- Practical support based on real factory cases

If you need guidance on improving burr control, spindle life, or overall cutting quality, please contact us. Our engineering team can provide technical recommendations tailored to your PCB material, thickness, and production goals.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)