规格

| 项目 | ZM300 | ZM300L |

|---|---|---|

| Effective Cutting Area | Upper suction: X350 × Y380mm Lower suction: X290 × Y320mm |

Upper suction: X450 × Y600mm Lower suction: X400 × Y570mm |

| Cutting Function | Straight line, L-shape, U-shape, circle, arc, irregular shapes | Same as ZM300 |

| Work Table | Dual table | Dual table |

| Repetition Accuracy | ±0.02mm | ±0.02mm |

| Cutting Accuracy | ±0.05毫米 | ±0.05毫米 |

| Max. Moving Speed | X: 1000 mm/s, Y1/Y2: 1000 mm/s, Z: 300 mm/s | X: 1000 mm/s, Y1/Y2: 1000 mm/s, Z: 500 mm/s |

| Max. Travel Range | X: 750 mm, Y1/Y2: 510 mm, Z: 100 mm | X: 950 mm, Y1/Y2: 880 mm, Z: 100 mm |

| Spindle Speed | Adjustable up to 60,000 RPM | Same as ZM300 |

| Tool Change Mode | Manual (standard) / Automatic (optional) | Same as ZM300 |

| Cutting Speed | Adjustable 1–100mm/s | Same as ZM300 |

| Operation Interface | Windows10 | Windows10 |

| Program Teaching Method | CCD color vision teaching input | Same as ZM300 |

| Program Backup | USB interface | Same as ZM300 |

| Control System | PC + motion control card | Same as ZM300 |

| XYZ Drive System | AC servo motor | AC servo motor |

| Applicable Cutter Size | Ø0.5–3.0mm | Ø0.5–3.0mm |

| Power Supply | AC220V 50/60Hz 2KW | AC220V 50/60Hz 2KW |

| Air Supply | 0.6Mpa | 0.6Mpa |

| Machine Dimension (W×L×H) | 1240 × 1050 × 1450mm | 1380 × 1591 × 1441mm |

| Machine Weight | 500kg | 700kg |

| Dust Collector Power | 4HP / 3HP / 5HP | Same as ZM300 |

| Dust Collector Size (W×L×H) | 600×500×1300mm / 600×600×1600mm / 813×925×1800mm | Same as ZM300 |

| Dust Collection Mode | Upper suction / Lower suction | Same as ZM300 |

| Dust Collector Power Supply | AC220V/380V 50/60Hz, 3-phase | Same as ZM300 |

| Dust Collector Weight | 125kg / 165kg / 290kg | Same as ZM300 |

Product Introduction

A four-axis motion control platform equipped with a high-speed, high-definition digital CCD camera for visual alignment and calibration, and the camera comes standard with barcode recognition capabilities.

A high-precision spindle with a speed of 60,000 RPM utilizes a dual-station platform for one-in, one-out PCBA replacement, significantly reducing waiting time and increasing production.

Quick and easy programming, equipped with a full-sheet scanning programming system, reduces line changeover time.

Equipped with a servo motor, ground lead screws, and guide rails, this system provides customers with a high-performance, highly secure, and highly stable PCBA depaneling machine.

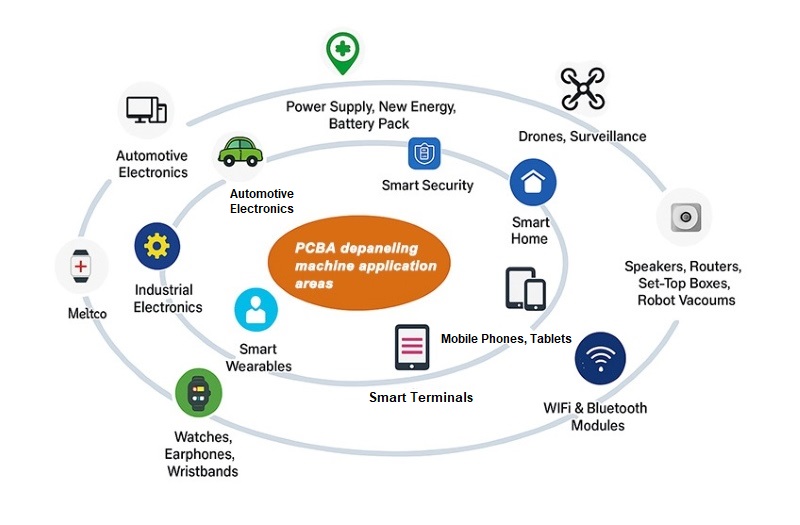

Application Cases

.png)

评价

目前还没有评价