In today’s highly competitive electronics manufacturing industry, PCB Panel Cutting Machines play a crucial role in ensuring efficiency, precision, and consistent product quality. As production demands rise and product designs become more complex, factories face increasing pressure to reduce waste, avoid defects, and maintain fast production cycles. Choosing the right PCB panel cutting solution is no longer optional—it’s essential for modern factories striving for operational excellence.

⚡ Enhancing Efficiency Through Precision

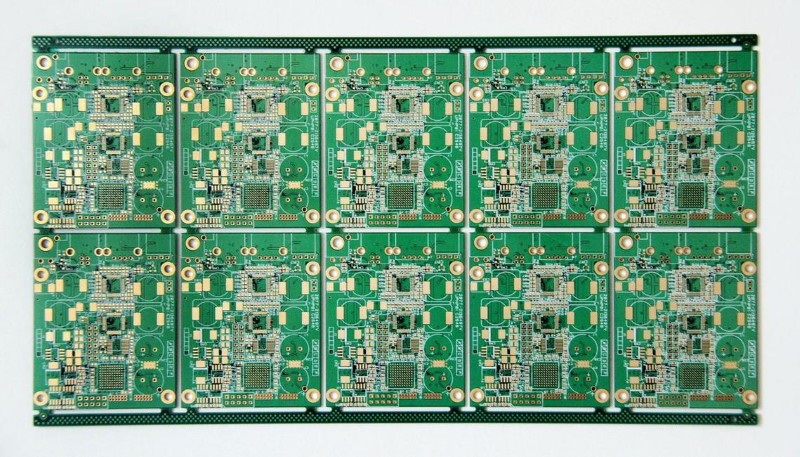

Precision is the cornerstone of effective PCB production. PCB panel cutting machines are designed to separate individual boards from large panels without causing damage or distortion. Even minor deviations in cutting can lead to board misalignment, soldering defects, and assembly issues downstream. By incorporating high-precision machines, factories can reduce rework rates and improve overall throughput.

For example, in high-volume production lines, automated depaneling machines can handle thousands of boards per hour, significantly outperforming manual cutting processes. This precision ensures that each board meets stringent design specifications, which is especially critical for industries like automotive electronics and medical devices.

🏷️ Cost Analysis: Balancing Investment and Returns

While the initial investment in PCB panel cutting machines can be significant, the long-term benefits often outweigh the costs. Consider these factors:

- Reduced Waste: Accurate cutting minimizes scrap material.

- Lower Labor Costs: Automated machines reduce the need for manual intervention.

- Tool Longevity: Advanced machines use optimized cutting methods that extend blade and spindle life.

- Fewer Defects: Minimizing board damage translates to less rework and higher customer satisfaction.

A case study in a mid-sized electronics factory showed that upgrading from manual routing to an integrated depaneling system reduced waste by 18% and increased throughput by 25% within six months—a tangible return on investment.

🔍 Addressing Common Pain Points

Modern factories face several challenges related to PCB panel cutting:

- Inconsistent Cutting Quality: Manual or outdated machines can create uneven edges.

- Downtime from Tool Wear: Frequent maintenance interrupts production.

- Complex Panel Designs: Multi-layer or irregular-shaped boards require adaptable cutting methods.

- Safety Concerns: Manual depaneling introduces risk to operators.

Advanced PCB panel cutting machines solve these problems through automated, programmable systems capable of precise cuts across diverse board types while maintaining a safer work environment.

📊 Real-World Applications and Case Studies

Many electronics manufacturers have successfully integrated PCB panel cutting machines to streamline production. For instance, a communication device manufacturer using high-speed, laser-based depaneling machines reported a 30% reduction in production cycle time. Another automotive electronics plant integrated jigless depaneling machines, which allowed faster setup times and eliminated the risk of board bending, leading to higher yield rates.

These examples demonstrate that investing in reliable PCB panel cutting machines is not merely about speed—it’s about consistent, high-quality production that supports long-term growth.

🧩 Future Trends: Smart and Connected Machines

As Industry 4.0 and smart factories become standard, PCB panel cutting machines are evolving to include features like:

- Real-time monitoring and predictive maintenance

- Integration with MES (Manufacturing Execution Systems)

- Adaptive cutting based on panel type or material

- Data analytics for performance optimization

These innovations help factories stay competitive, reduce costs, and respond quickly to market demands.

.jpg)

✅ Why Choose Seprays Group?

For over 30 years, the Seprays Group has been a leading supplier of PCB panel cutting solutions, combining technological innovation with extensive factory experience. Our machines are designed to be precise, efficient, and reliable, effectively addressing the real pain points of electronics manufacturers. From reducing waste and maintenance costs to increasing throughput and product quality, Seprays offers tailored, comprehensive solutions to meet your production needs.

For any questions or to learn more about our PCB panel cutting machines, please do not hesitate to contact us. Our team is ready to provide professional guidance and support.

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)