Specifications

| Model | ZM30-A |

|---|---|

| Size | 1500*800*1500mm |

| Shape | Vertical |

| Weight | 300KG |

| Color | computer white |

| Power supply | AC220V 1000W |

| Environmental requirements | clean and dry environment, avoid humidity or high temperature |

| Working air pressure/tube diameter | >0.6MP/8mm |

| Minimum cutting distance | ≥1.5mm |

| Splitting width | 300mm*300mm / 12*12mm |

| Board inlet adjustment | front side fixed, rear side movable adjustment |

| Maximum height of PCB components | 20mm for PCB reverse side parts, 35mm for front side parts |

| Parameter setting | According to the size of the V-slot touch screen, direct input |

| Storage module | can store 50 groups of programs |

| Blade | Japan imported a high-speed steel knife |

| Blade angle | 10-30 degrees (selectable) |

| Die precision | 0.1mm |

| Partitioning efficiency | 15s/pcs(200*150mm) standard speed cut 8 knives for reference |

| Maximum length and width of the assembly line | 650mm*250mm |

| Split board speed | 0-800mm/s |

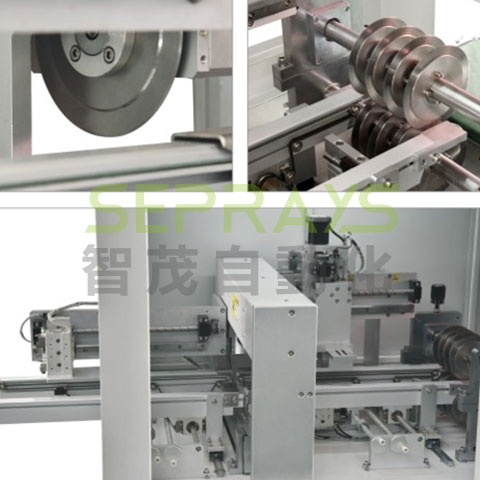

| Suction cup manipulator control mode | stepping motor + guide rail + belt drive |

| Dust suction mode and power | 1500W under the knife group dust suction |

| Board thickness | 0.4-3.5mm |

| Misoperation protection | triple protection of grating, sensor, and software. |

| Safety protection | emergency stop |

| Power failure and air cut-off function | Yes |

| Self-test function | power-on time monitoring, capacity monitoring, equipment failure information, and an automatic elimination system |

| The main parts of the machine | board feeder (assembly line), suction cups, three-axis mobile slitting flat, vacuum cleaner |

| Work mode | automatic robot online slitting and feeding boards |

| Suitable for | Insertion / SMD / Dual Direction |

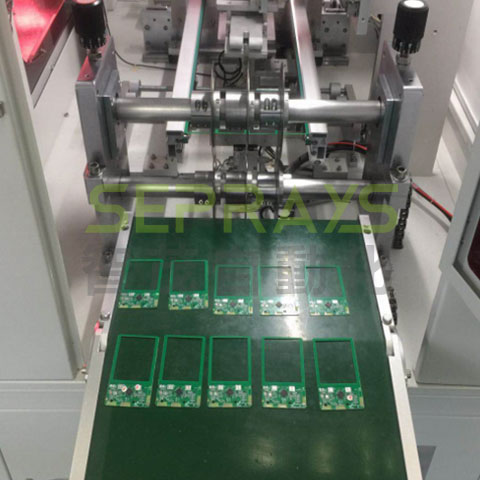

SEPRAYS specifically engineered the ZM30-A V-groove depaneling machine for high-precision depaneling of PCBA boards after component insertion.

Designed to protect delicate components during the cutting process, it enhances safety while boosting downstream production efficiency.

This machine features a dual-knife cutting mechanism, enabling fast and accurate separation through multiple V-groove tracks. With optional automation modules—including automatic feeding, slitting, and board receiving—the ZM30-A V-groove depaneling machine ensures smooth, operator-friendly performance that significantly increases throughput.

Its configurable parameters allow for fine-tuned operation, while multi-head tooling enables quick and consistent slitting across multiple board groups. The separator also supports automatic output and docking with subsequent systems, ensuring uninterrupted workflow across your production line.

.png)

评价

目前还没有评价