Specifications

| Item | ZM300SV | ZM300SVL |

| Cutting Range | 370×420 mm | 400×500 mm |

| Cutting Function | X, Y direction: Straight line | |

| Worktable | Dual worktables | |

| Repeat Accuracy | ±0.01 mm | |

| Cutting Accuracy | ±0.15 mm | |

| Max. Moving Speed | X, Y: 1000 mm/s; Z: 500 mm/s | |

| Max. Travel (mm) | X: 980, Y: 770, Z: 50 | |

| Spindle Speed | Max: 6,000 rpm | |

| Cutting Speed | 1–100 mm/s adjustable | |

| Operating System | Windows 10 | |

| Programming Method | CCD color image intuitive teaching input | |

| Control System | Precision multi-axis control system | |

| XYZ Axis Drive | Y, Z: AC servo motor; X: Linear motor | |

| Applicable Cutter Size | Outer φ75 mm; Inner φ16 mm | |

| Power Requirement | AC220V single-phase 50/60Hz, 2.2KW | |

| Air Requirement | 0.6 Mpa, 80 L/min | |

| Dimensions (W×D×H) | 1370×1480×1590 mm | |

| Weight | 730 KG | |

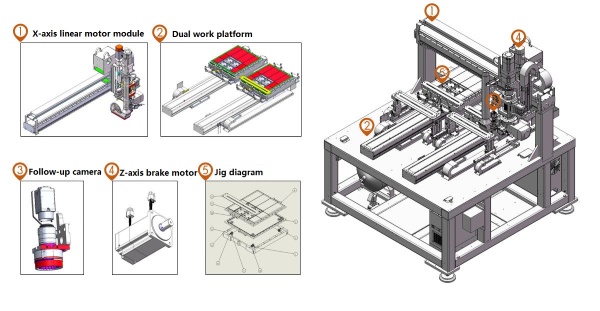

Device Main Architecture

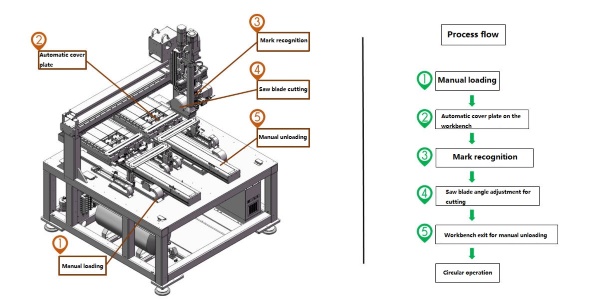

Equipment Workflow

Main Equipment: Dust Collector

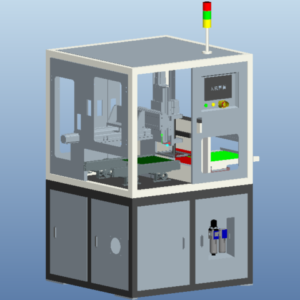

The ZM300SV is an advanced offline PCB depaneling solution, engineered for maximum performance in high-volume manufacturing environments. This model utilizes a direct-drive high-power electric spindle for consistent cutting precision and stability, even with complex designs. A high-speed CCD vision system ensures perfect alignment and recognition of PCB marks, while its cover plate and high negative pressure adsorption ensure secure fixation, further enhancing cutting accuracy.

Key features include:

-

High-Precision Cutting: Achieved through a high-power direct-drive spindle and a high-speed CCD vision correction system.

-

Flexible Cutting Angles: The machine allows free switching between 90° and 180°, enabling one-time efficient cuts.

-

Stability and Reliability: The use of linear motors and servo motors guarantees stable operation and long-term durability.

-

Safety and Convenience: Equipped with a double-door safety guard, automatic cover pressing, and barcode recognition capabilities for enhanced operational safety and convenience.

Specifications:

-

Dimensions: 1370mm x 1480mm x 1590mm

-

Main Structure: X-axis linear motor module, dual working platforms, and servo motor-driven Z-axis brake motor.

-

Cutting Angle: 90° or 180° adjustable.

-

Additional Features: Optional automatic height measurement, safety light curtain, and barcode camera.

Use Cases and Applications:

-

Electronics Manufacturing: Perfect for the precise separation of PCBs in high-demand environments like smartphone, automotive, and computer manufacturing.

-

High-Volume Production: Designed to support continuous operation with minimal downtime, suitable for large-scale production lines.

Why Choose ZM300SV/300SVL?

The ZM300SV/300SVL stands out for its blend of cutting-edge technology, ease of use, and superior performance. It offers:

-

Unmatched Accuracy and Efficiency: Consistent high-precision cutting and fast operation.

-

Versatility: Adaptable to a wide range of PCB designs and cutting requirements.

-

Superior Support: Backed by a comprehensive warranty, lifetime maintenance, and a global service network, ensuring your operations stay uninterrupted.

Contact Us for Pricing & Details

Contact Us for Pricing & Details

Email: sales@seprays.com

WhatsApp: +86-189 2926 6433

.png)

Contact Us for Pricing & Details

Contact Us for Pricing & Details

评价

目前还没有评价