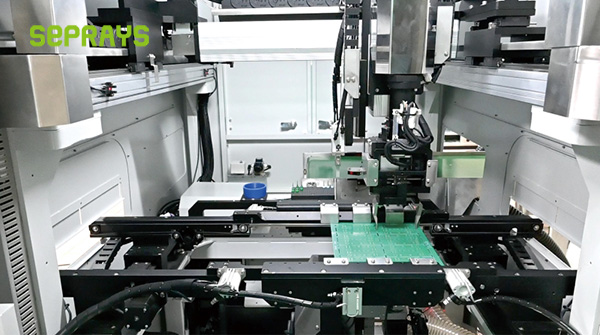

⚙ A PCB depaneling machine plays a vital role in modern electronics manufacturing. As circuit boards become thinner, smaller, and more complex, manual separation can no longer meet production demands. Stress, cracks, and hidden damage are common when PCBs are broken by hand. Automated depaneling machines solve this challenge by ensuring precise, low-stress separation that protects components and improves yield.

✂️ Why Stress Matters in PCB Separation

When boards are separated from panels, excessive mechanical force can lead to micro-cracks in solder joints. These defects may not appear immediately, but can cause long-term failures.

A PCB depaneling machine reduces stress by applying controlled cutting methods. This ensures that delicate components and fine traces remain intact, safeguarding both performance and reliability.

🛠 Methods of Stress-Free Separation

Modern depaneling machines use a range of cutting techniques:

- V-groove cutting – clean breaks along pre-scored lines.

- Milling cutters – precise routing for complex shapes.

- Laser cutting – contactless separation with no physical stress.

- Punching – fast removal for high-volume production.

Each method has unique benefits, but all share one goal: reducing stress and protecting the board.

📏 Accuracy and Consistency

Manual separation is inconsistent and depends on operator skill. Automated machines, by contrast, deliver repeatable accuracy.

A high-end PCB depaneling machine can achieve ±0.05 mm repeatability. This precision ensures smooth edges, a perfect fit for enclosures, and fewer assembly errors downstream.

🚀 Production Efficiency

Efficiency is critical in today’s electronics industry. Automated depaneling significantly reduces cycle times and labor costs.

Instead of relying on multiple operators, a machine can separate hundreds of boards per hour with consistent quality. This not only boosts throughput but also frees up labor for higher-value tasks.

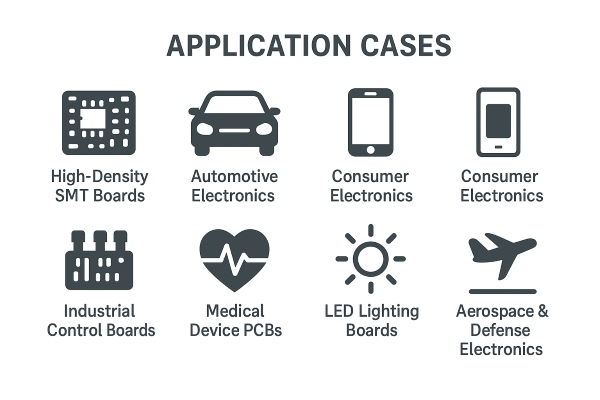

🌍 Industries That Benefit

Stress-free depaneling is essential in industries where reliability cannot be compromised:

- Automotive – safety-critical control units and sensors.

- Medical devices – equipment that requires zero tolerance for defects.

- Telecom – high-speed boards with sensitive circuits.

- Consumer electronics – compact designs with tight layouts.

- LED lighting – mass production requires fast and clean separation.

Across these sectors, reducing damage during separation directly translates to higher yields and lower costs.

🧹 Cleaner and Safer Production

Many machines also integrate dust collection and ESD protection. Dust-free operation prevents contamination, while anti-static features shield sensitive chips from damage.

Together, these systems improve board reliability and extend product lifespan, creating long-term value for manufacturers.

💡 The Future of PCB Depaneling

As boards continue to shrink and designs grow more complex, depaneling machines will evolve further. Expect more AI-driven alignment, smarter automation, and flexible systems that adapt to multiple production needs.

This evolution will make low-stress, damage-free separation the industry standard.

🌟 Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

We help manufacturers improve efficiency, reduce waste, and achieve higher yields with confidence.

📧 If you need support, please contact us today.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)