Specifications

| Model | GAM380AT |

|---|---|

| Valid cutting size | 500*450mm |

| Loading method | Track delivery |

| Unloading method | Conveyor belt delivery or track delivery |

| Transfer method | The rotatable gripper for taking |

| Movement direction | Left to right or right to left |

| Cutting function | Tweening to a straight line, L shape, U shape, Circle, Arc |

| PCB specification | Weight≤3kg, edge width≥3mm, thickness 0.8-4mm |

| Repeat precision | ±0.01mm |

| Cutting precision | ±0.1mm |

| Max moving speed | XY: 1000mm/sec, Z: 800mm/sec |

| Spindle’s speed | MAX: 60000rpm (Adjustable) |

| Tool change type | Auto tool change |

| Cutting speed | 1-100mm/s |

| Broken knife check | Included |

| Operating system | Windows10 |

| The program teaching method | Intuitive teaching by CCD color image input |

| Control method | Precision multi-axis control system |

| XYZ axis driving mode | AC Servo motor |

| Size of milling tool | 0.8-3.0mm |

| Voltage/Power requirement | AC220V 50/60Hz 4KW Single-phase |

| Pneumatic pressure requirement | 0.6MPa, 160L/min |

| Dimensions(W*D*H) | 1252*1859*1735mm |

| Weight | 770kg |

| Dust collector | TS300L |

Product Introduction

- Jig-free cutting.

- Outfeed can be arranged in rows at 0-180 degrees, allowing integration with back-end equipment.

- Railway feeding and outfeed options include belt, rail, and jig feeding.

- A high-speed ESD automatic tool changer actively dissipates static electricity generated during the depaneling process, reducing damage to PCBAs caused by static electricity.

- Features include milling cutter life management, maintenance alerts, and spindle speed settings.

- 6HP high-suction dust collector with negative pressure detection to remind filter bag cleaning.

- Windows 10 operating system. Software developed automatically for continuous feature upgrades.

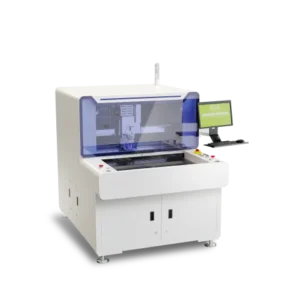

The GAM 380AT PCB depaneling machine by SEPRAYS is a versatile, high-precision solution designed for efficient bottom depaneling of printed circuit boards without the need for fixtures. Its innovative gripper cutting technology accommodates PCBs with high components on top, ensuring safe and damage-free separation.

Equipped with a CCD vision positioning system, the GAM 380AT PCB depaneling machine delivers precise offset alignment for every cut, guaranteeing consistent accuracy. The machine offers flexible unloading options, including conveyors, tracking, and customized placing boards, adaptable to your production line setup.

Optional features include fixed or variable pitch jaws, barcode reader, milling tool diameter detection, and customized MES integration for enhanced process control.

Trusted by over a thousand leading global companies, SEPRAYS continues to set industry standards.

Products Features

Jig-free cutting

- No custom jigs required, allowing for direct board separation

- Outfeed can be rotated 0-180 degrees to position the entire board for accurate cutting

CCD vision automatic calibration system

- Equipped with a high-speed CCD vision automatic calibration system

- Simulated cutting paths assist with programming, ensuring accurate cutting paths

- Full-board scanning and offline programming improve path editing efficiency

Offline programming and full-board scanning

- Cutting programs can be edited offline and directly imported into the machine, improving utilization.

- Easier, more user-friendly, and automatic cutting path recognition

- Editing after scanning the entire PCB allows for quick modification of cutting paths, improving programming efficiency

- Selectable cutting line colors facilitate the identification of different PCB colors

Quick line change

- Recall existing programs to avoid jig errors, enabling quick program recall and line change.

High utilization

- With over 30 years of independent software development, the board separation machine utilizes stable and reliable software, eliminating board defects caused by bugs.

Unique Features

- The panel splitter features a one-piece welded design for stability and strength.

- Made from cast aluminum, it resists oxidation, deformation, and shifting, ensuring a long lifespan and guaranteed precision.

Application Cases

The GAM380AT fixture-free, fully automatic PCB depaneling machine offers seamless flexibility and integration with front-end and back-end automation.

FAQ

What services do you provide?

We provide one-stop automated PCB depaneling solution, including: laser, routing, punching,g, and V-CUT.

Can your machines handle different thicknesses of PCBs?

Yes, our machines are designed to handle a wide range of PCB thicknesses. We can provide customization and options to ensure smooth processing of both rigid and flexible boards.

What type of training do you provide for your machines?

We provide comprehensive on-site training, covering machine operation, maintenance, and troubleshooting. We also offer ongoing technical support via phone and email.

What after-sales services can you provide?

● Exclusive service:

We will give users feedback within 10 minutes on any problems they encounter when using the device, and establish a 1V1 exclusive after-sales service group for users.

● Remote service:

Provide users with a 7/24-hour hotline based on feedback on fault information, analyze, locate, and solve the fault through remote telephone support, remote login, and other methods.

● On-site service:

Arrive at the work site within 8 hours and solve the problem within 1 working day. 2-4 days of training on equipment safety, operation, and application. Any breach of contract will be handled by the contract provisions.

● Service locations:

We have sales and service support in 31 countries and regions overseas, responding to customers’ current and future needs as soon as possible.

● Benchmark service:

Follow-up call after each visit; video tutorials + telephone guidance on parts replacement and equipment maintenance; free follow-up month in December every year. We continue to collect user suggestions, continuously update and iterate the software, improve user production quality and efficiency, and provide lifelong maintenance.

Application Areas

Our PCB depaneling solutions are widely used in industries that require high-precision and high-efficiency board separation.

Key application areas include:

- Consumer Electronics – Smartphones, tablets, laptops, and wearables.

- Automotive Electronics – PCBs for ADAS, infotainment systems, and EV components.

- Medical Devices – Precision electronics in diagnostic and monitoring equipment.

- Telecommunications – Network and communication hardware.

- Industrial Electronics – Control systems, automation equipment, and IoT devices.

- Aerospace & Defense – High-reliability PCBs for avionics and military applications.

📩 Contact us now with your product image, and we’ll recommend the perfect depaneling solution for you!

.png)

评价

目前还没有评价