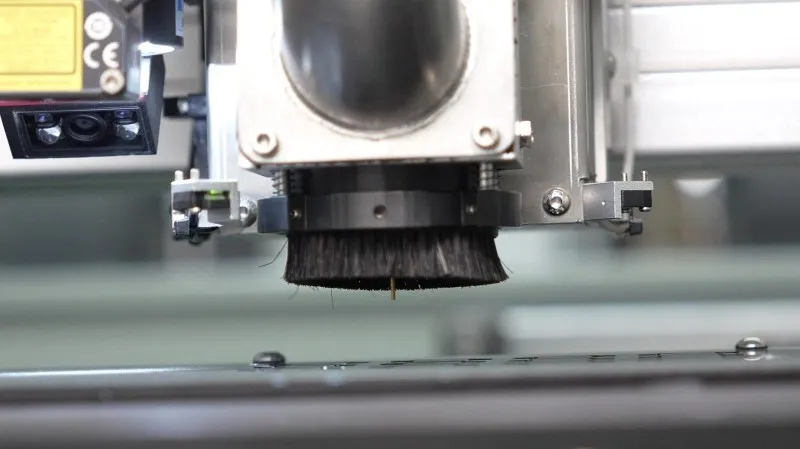

Milling cutter PCB depaneling machine burr formation is one of the most common concerns raised by process engineers—especially when boards move directly into functional testing, coating, or final assembly. Burrs may look minor, but in high-density or high-reliability electronics, they can become a real quality risk.

So, will burrs appear after milling and depaneling? The realistic answer is: they can—but they are controllable. This article shares production-level insights from EMS and OEM factories, focusing on industrial quality, durability, and practical process control rather than idealized claims.

🧠 What Engineers Mean by “Burrs” in PCB Depaneling

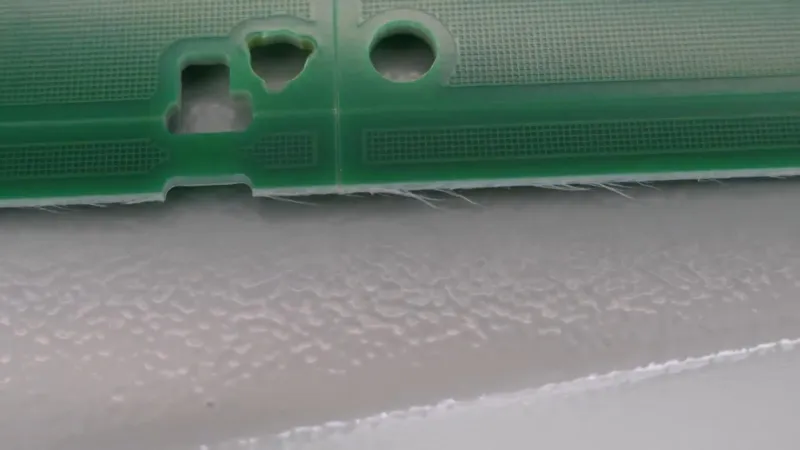

In real production, burrs typically refer to:

- Small fiberglass or resin fibers along the board edge

- Micro copper protrusions near ground planes or pads

- Edge roughness is visible under magnification

Not all burrs are equal. Some are cosmetic, while others can interfere with connectors, housings, or conformal coating.

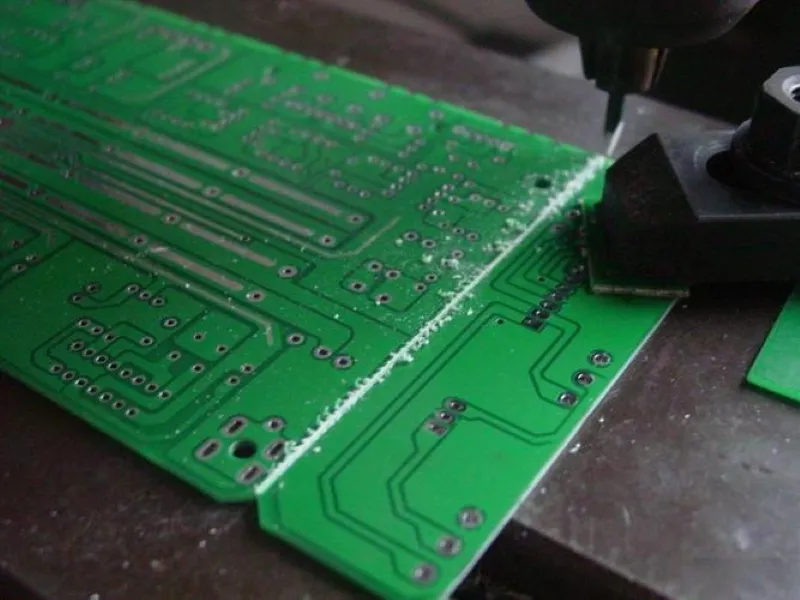

⚙️ Why Burrs Occur During Milling Depaneling

Milling is a mechanical cutting process, so burrs are influenced by multiple interacting factors:

- Tool sharpness and flute geometry

- Cutting direction relative to copper layers

- Feed rate and spindle speed balance

- PCB material composition (FR4 grade, Tg, filler content)

In many cases, burrs are not a machine problem—but a process setup issue.

🪚 Tooling Choices Make a Bigger Difference Than Expected

Production data shows that the tooling strategy is often the deciding factor:

- Worn cutters dramatically increase edge fiber pull-out

- An incorrect cutter diameter raises sidewall stress

- Improper coating accelerates resin smearing

Factories that shifted from time-based to cut-length-based tool replacement saw a clear reduction in burr-related rework.

🧩 Panel Support and Fixturing: An Overlooked Cause

Insufficient board support allows micro-vibration during routing, which leads to:

- Irregular edge tearing

- Localized burr clusters near corners

- Inconsistent edge quality across the same panel

Full-area vacuum fixtures and stable clamping often reduce burrs more effectively than changing cutting parameters alone.

📉 Cost Impact: Small Burrs, Large Consequences

While minor burrs may seem harmless, their downstream cost can be significant:

- Manual deburring labor

- Increased AOI false calls

- Poor adhesion of coatings or adhesives

- Risk of ESD or conductive debris

Several EMS factories reported that burr-related touch-up consumed more time than the depaneling step itself.

🏭 Case Insight: Consumer and Industrial Mixed Line

A mixed-production SMT line handling both consumer and industrial PCBAs struggled with inconsistent edge quality. By optimizing cutter geometry, adjusting feed rates, and improving dust extraction near the cutting zone, burr occurrence was reduced to a level acceptable for both product categories—without slowing throughput.

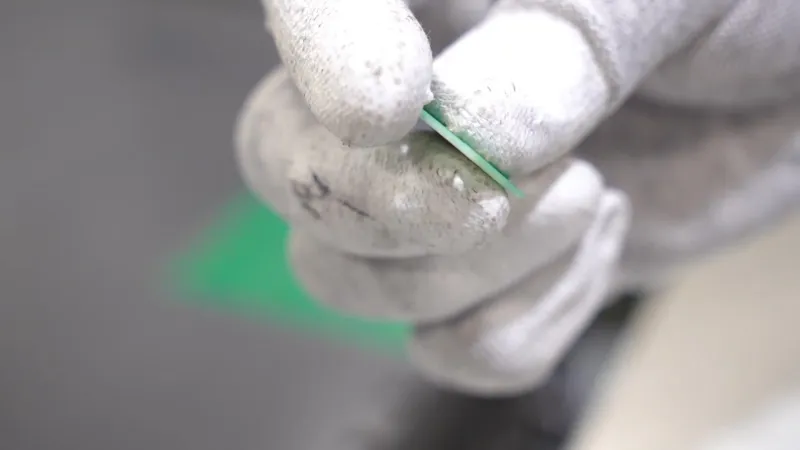

🛠️ Practical Ways to Minimize Burrs in Daily Production

Experienced engineers commonly recommend:

- Match cutter type to PCB material, not just thickness

- Maintain consistent spindle load rather than maximum speed

- Inspect edge quality under magnification during trials

- Treat fixtures and tooling as part of the cutting system

In practice, burr control is a process discipline, not a single setting.

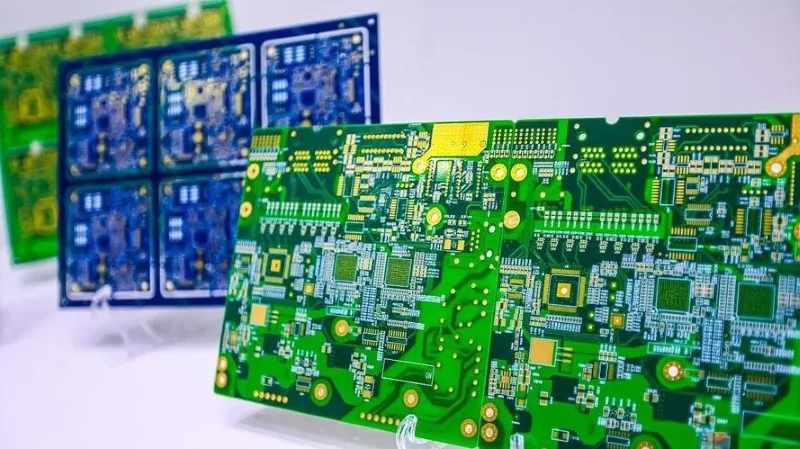

🌍 Meeting Global Quality Expectations

For automotive, medical, and industrial electronics, clean board edges are increasingly part of quality audits. Milling depaneling can meet these expectations when the system is designed for industrial durability and operated with proper controls.

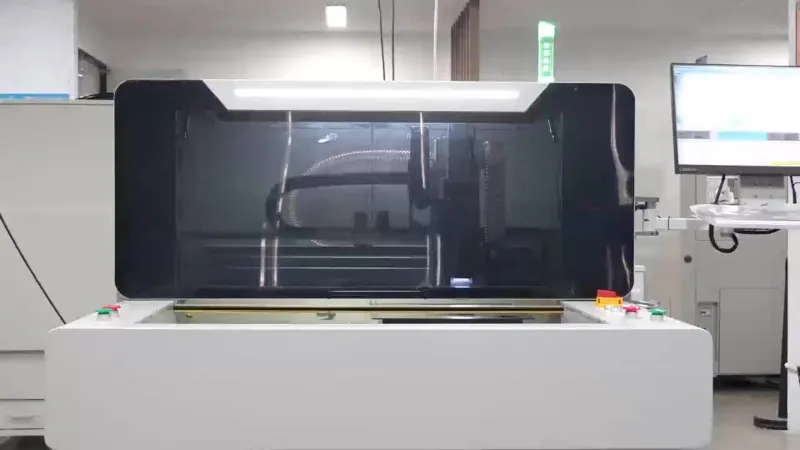

💬 Why Choose Seprays Group?

Seprays Group provides industrial-grade milling cutter PCB depaneling machines designed to deliver stable edge quality, long-term durability, and consistent performance across demanding production environments. Our focus is on helping engineers reduce burrs through system-level design—not post-process fixes.

If you would like to discuss burr control strategies for your specific PCB application, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)