The choice between router depaneling y V-cut largely depends on the design and requirements of your PCBA. While both are popular methods for separating boards, each method offers distinct advantages depending on factors like board thickness, component sensitivity, and precision needs. This article will explore when router depaneling is the better choice over V-cut, with a focus on practical considerations and real-world examples.

⚙️ What are the differences between router depaneling and V-cut?

Before we discuss when router depaneling is preferred, let’s compare both methods briefly.

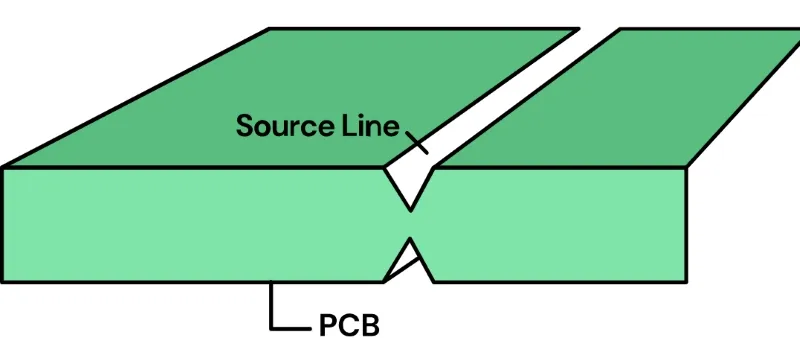

V-Cut Depaneling:

- How it works: A V-shaped groove is cut into the PCB to create a scored line, allowing the board to break cleanly along the groove.

- Best for: Thin PCBs with low mechanical stress tolerance.

- Limitations:

- Only works with specific materials (usually standard FR-4).

- Requires larger keep-out areas due to tool diameter.

- Not suitable for complex or irregular board shapes.

Router Depaneling:

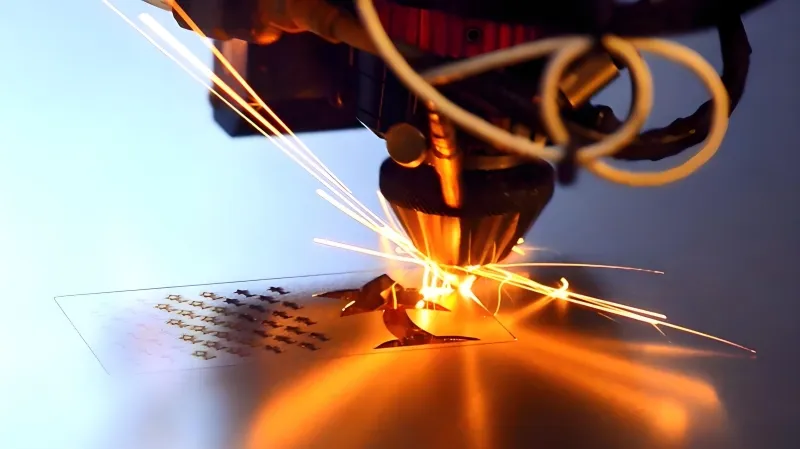

- How it works: A rotating tool (router) physically cuts through the PCB, separating it into individual panels.

- Best for: Thicker boards, complex designs, or materials that cannot be scored with a V-cut.

- Advantages:

- Can handle high-density PCBs.

- More flexibility with cut shapes (e.g., curved or irregular cuts).

- Lower mechanical stress on the PCB compared to V-cut.

🔍 When should you choose router depaneling over V-cut?

Router depaneling is the preferred choice in the following situations:

1. Thicker PCBs or Rigid-Flex Designs

For thicker boards (greater than 1mm) or rigid-flex PCBs, router depaneling provides the cutting power needed to maintain clean, stress-free separation. V-cuts are usually too shallow for thicker boards and may lead to breakage or incomplete separation, especially when dealing with multiple layers.

Example:

A medical device manufacturer needed to process rigid-flex boards with multiple layers of sensitive components. Router depaneling provided precise cuts without damaging internal layers or causing delamination. V-cut wasn’t an option because it didn’t offer enough depth to handle these complex materials.

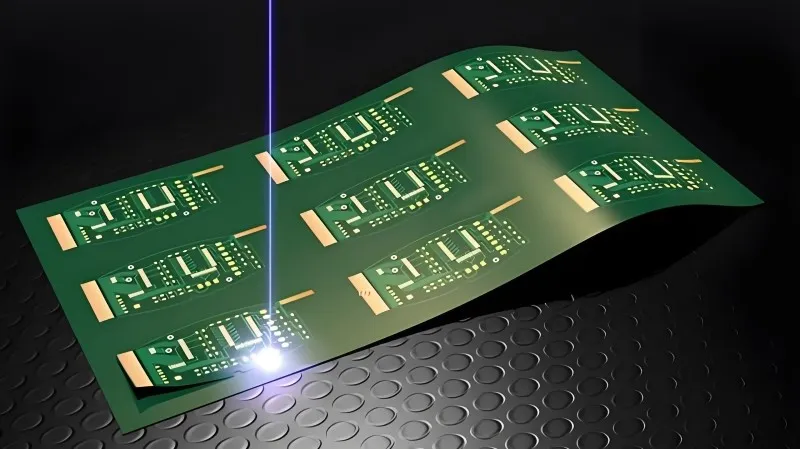

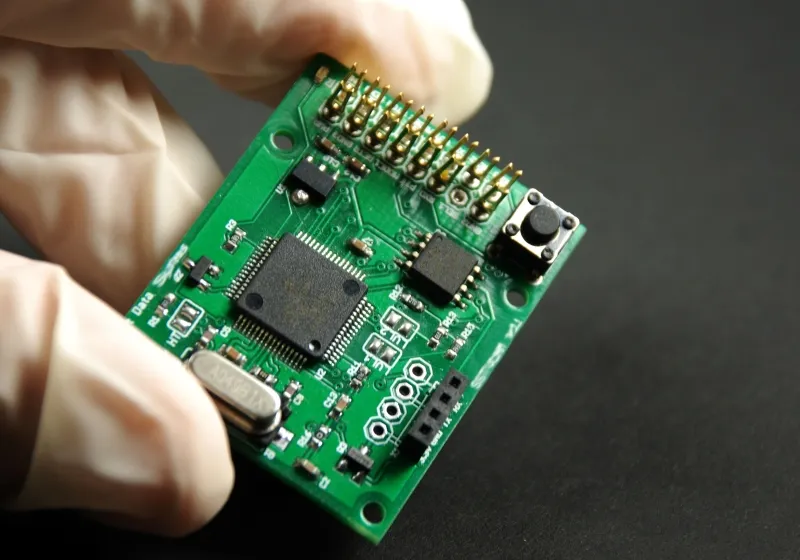

2. High-Density PCBs with Small Components

When working with high-density PCBs, where components are tightly packed, router depaneling is superior. V-cut processes require larger keep-out areas, which can reduce the usable area of the PCB. Milling cutter depaneling can achieve tighter tolerances, which helps maintain the component placement integrity.

Example:

A consumer electronics company working on smartphone PCBs opted for router depaneling to ensure the tightest tolerance around small components. The V-cut process, which required more space around components, was not viable for this design.

3. Irregular or Complex Cutting Paths

If your PCB requires curved or non-linear cuts, router depaneling is the go-to solution. V-cut can only create straight-line separations and is limited by the geometry of the groove. In contrast, router depaneling offers more flexibility, making it ideal for custom shapes or boards with non-standard outlines.

Example:

A manufacturer of automotive sensors required precise cuts around irregularly shaped PCBs. Router depaneling allowed for highly accurate, non-linear cuts, which would have been impossible with V-cut.

4. Sensitive Components

For sensitive components (such as capacitors, sensors, or connectors), router depaneling is less likely to cause the mechanical stress associated with V-cut separation. The V-cut process, while effective for simpler designs, can cause cracks or damage to these sensitive components due to the pressure applied when separating the board.

Example:

A medical PCB manufacturer faced failure issues when using V-cut on boards with sensitive medical-grade components. Switching to router depaneling resolved the issue, ensuring no stress-induced damage during the depaneling process.

💡 Advantages of Router Depaneling over V-Cut

The benefits of choosing router depaneling are clear in specific applications:

- Lower mechanical stress: Router depaneling avoids the issues of stress cracking associated with V-cut methods.

- Precise cuts: Offers more control over cutting paths and tolerances, making it ideal for high-density, complex designs.

- Flexibility with material: Works well with a wider range of materials, including rigid-flex and thicker boards.

- No need for keep-out zones: Unlike V-cut, router depaneling can process designs with minimal gaps between components.

💰 Cost Considerations – Is Router Depaneling Worth It?

While router depaneling systems are generally more expensive than V-cut solutions, the long-term benefits often justify the cost, particularly for:

- High-value PCBs with sensitive or complex designs

- Lower scrap rates due to better edge quality

- Reduced labor costs as router depaneling systems are often automated, requiring less manual intervention

For simpler designs or low-cost boards, V-cut may still be the more economical choice. However, for high-reliability, high-performance boards, the cost of router depaneling is often outweighed by its precision and durability.

🧪 Case Insight from Production

A Seprays router depaneling system was implemented by a semiconductor manufacturer working with high-density PCBs that contained a mix of small components, high-frequency traces, and sensitive capacitors. Previous attempts with V-cut resulted in cracking and reliability issues during functional testing.

With router depaneling, they achieved:

- Cleaner, stress-free edges

- Improved long-term reliability of solder joints

- Increased panel utilization due to more precise cutting paths

This solution not only solved their quality issues but also boosted throughput without compromising the integrity of the PCBs.

🛠️ Seprays Router Depaneling Advantages

Seprays offers router depaneling solutions designed to address common challenges in high-precision, high-density applications:

- Mark point auto-correction: Ensures precise cutting paths by scanning and adjusting based on mark points.

- Tool life management: Tracks tool usage and automatically compensates for wear, reducing variability.

- Multi-mark point functionality: Automatically corrects for minor position shifts during cutting, ensuring consistency.

- Advanced CCD scanning: Offers real-time scanning and programming, reducing manual setup and errors.

- Offline programming and efficient file sharing with network integration for faster turnaround.

- Automatic tool change and breakage detection to minimize downtime and ensure continuous production.

⭐ Why Choose Seprays Group?

Seprays focuses on offering precise, automated solutions that handle complex and high-precision PCB designs. With our advanced router depaneling systems, you can optimize production efficiency, reduce scrap, and increase yield, even with challenging designs.

If you’re unsure whether router depaneling or V-cut is the best choice for your PCBs, póngase en contacto con nosotros for a consultation or sample evaluation.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)