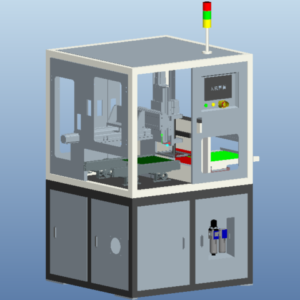

Descripción

| Elemento | Especificación |

| Modelo | ZM300ASV |

| Valid Cutting Size | 350 × 350 mm |

| Table Size | 370 × 400 mm |

| Working Height | 900 ± 20 mm |

| Process Table | Tablas dobles |

| Cutting Precision | De ±0,2 mm |

| Repeat Precision | ±0,02 mm |

| La Velocidad De Corte | 100 mm/s |

| La arquitectura | Rail feeding; manipulator for loading & unloading; circular cutter head / V-cutting head with horizontally adjustable height |

| El Método De Alimentación | Track entry, PCB directly flows in |

| Discharging Method | Module output / Belt line output / Track output |

| El Método De Transferencia De | Manipulator handling, vacuum suction |

| Movement Direction | De izquierda a derecha o de derecha a izquierda |

| Max Moving Speed | 1000 mm/s |

| Max Moving Travel | Manipulator X-axis 1: 610 mm; Sub-board X-axis: 530 mm; Sub-board Y-axis: 600 mm |

| Operation Interface | Windows 10 |

| Program Teaching Method | Manual teaching / CAD import |

| Programa De Copia De Seguridad | Transferencia de datos por USB |

| Working Air Pressure | 4.5 ~ 6 kgf/cm² |

| Voltage / Power Requirement | AC 220 V ±10%, 50/60 Hz, 2.5 KW |

| Dimensions (W × D × H) | 1180 × 1246 × 1684 mm |

| Peso | 1000 kg |

Introducción De Producto

The “V”-groove PCB splitter provides higher-quality PCB separation.

Fully automated operations include feeding, cutting, finished product discharge, and waste collection.

Automatic PCB separation in both the X and Y directions with the V-groove.

Smooth, burr-free slitting of aluminum, copper, FR4, and fiberglass substrates.

During line changes, operators can swap the cutting die and suction cup, eliminating manual tool adjustments and saving time.

The system automatically places small PCBs in trays or removes them from the assembly line based on customer needs.

Características

Operation Screen

- Simple settings for panel separation and milling cutter/fixture parameters.

- Processing efficiency and milling cutter usage data are clearly displayed.

- A history window facilitates operation log review.

- Equipped with milling cutter life management, maintenance alerts, and spindle speed settings.

Four-level user access control

- User accounts and passwords can be set to differentiate access levels based on management needs.

- You can add a fingerprint login module to simplify management.

CCD vision automatic calibration system

- Equipped with a high-speed CCD vision automatic calibration system.

- Cutting path simulation assists programming, ensuring accurate cutting paths.

- Completa la hoja de exploración y programación fuera de línea de mejorar la ruta de la eficiencia de la edición.

Offline programming and full-sheet scanning

- Cutting programs can be edited offline and directly imported into the machine, improving utilization.

- Simpler, more user-friendly, automatic cutting path recognition.

- Scan and edit the entire PCB board, allowing quick modification of the cutting path and improving programming efficiency.

- Selectable cutting line colors facilitate the identification of different PCB colors.

High-speed cutting spindle

- Imported high-speed, high-precision spindle

- Low cutting stress, smooth board edges, and high precision

- High-precision spindle speed of 80,000 rpm/min

High utilization rate

- With over 30 years of independent software development, the splitter utilizes independently developed software, ensuring stability and reliability, eliminating board defects caused by bugs.

Aplicación De Casos

.png)

Valoraciones

No hay valoraciones aún.