Depaneling for Automotive Electronics has become a critical discussion point as vehicle electronics move toward higher integration, longer service life, and stricter reliability standards. In automotive SMT production, depaneling is no longer viewed as a simple mechanical step, but as a process that directly influences component integrity and field performance. This article compares stress behavior across common cutting technologies based on shared industry experience.

🚗 Why Stress Control Matters in Automotive PCBs

Automotive electronics are exposed to vibration, thermal cycling, humidity, and long operating hours. Engineers consistently point out that stress introduced during depaneling can remain hidden until later validation stages—or worse, after deployment has occurred.

Typical risks include:

- Micro-cracks in ceramic capacitors

- Solder joint fatigue near board edges

- Reduced insulation resistance over time

Because these failures often appear late, depaneling-related stress is treated as a preventive quality concern rather than a visible defect.

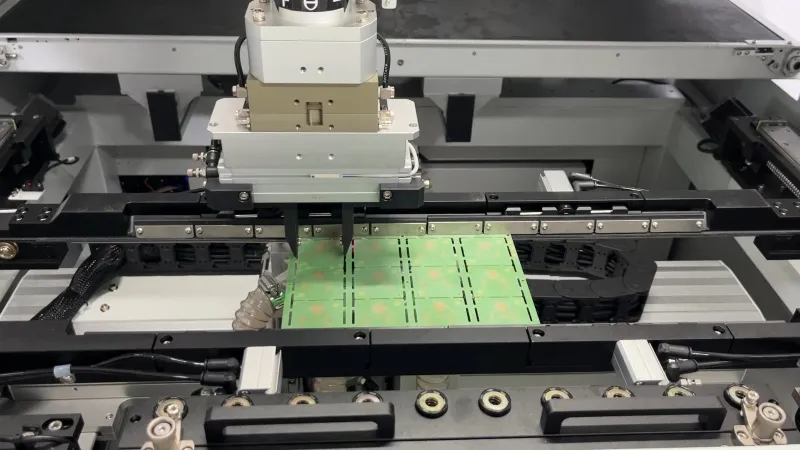

🪚 V-Cut Depaneling — Efficiency with Mechanical Trade-Offs

V-cut depaneling remains a common practice in automotive production when board designs are stable, and edge clearance is sufficient.

Observed characteristics:

- High efficiency in large-volume production

- Simple process control

- Low initial investment

However, engineers frequently note that the snapping force concentrates stress along the score line. In automotive applications, this requires conservative design rules, controlled separation speed, and strict blade maintenance to reduce variability.

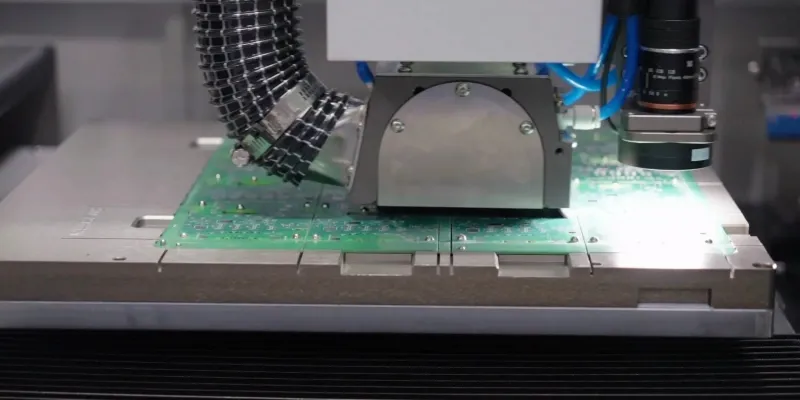

⚙️ Router Depaneling — Balanced Stress Distribution

Router-based depaneling is often selected when stress sensitivity increases.

From production feedback:

- Gradual material removal reduces sudden force

- Better compatibility with dense layouts

- More predictable results across different panel thicknesses

The main discussion point is durability. Long-term stress control depends on spindle stability, machine rigidity, and vibration management—factors that directly affect consistency over thousands of cycles.

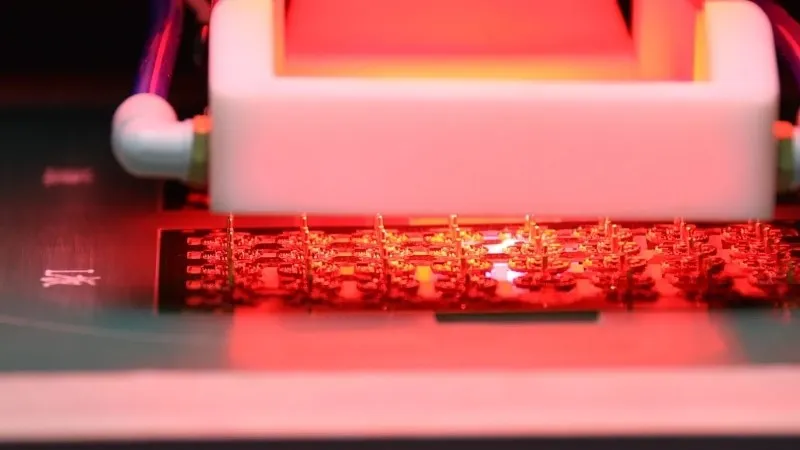

🔥 Láser Depaneling — Minimal Mechanical Stress, New Considerations

Laser depaneling is increasingly evaluated for stress-sensitive automotive electronics.

Advantages reported:

- No mechanical contact with the PCB

- Excellent edge quality for thin boards

- High repeatability

At the same time, engineers highlight considerations such as thermal influence on materials, process speed, and higher system cost. As a result, laser solutions are typically applied to high-value or highly sensitive automotive modules rather than general-purpose boards.

📉 Cost Analysis — Stress vs. Lifecycle Expense

Automotive manufacturers emphasize that the depaneling cost must be viewed across the product lifecycle.

Hidden costs often include:

- Field returns linked to latent stress defects

- Extended validation and testing cycles

- Yield loss during thermal and vibration testing

- Additional inspection near board edges

Several production teams report that reducing depaneling stress lowered overall quality-related cost, even when equipment investment increased.

🏭 Case Insight from Automotive SMT Production

One automotive electronics supplier observed intermittent capacitor failures during thermal cycling. Root-cause analysis traced the issue back to depaneling stress near densely populated edges. After adjusting the cutting method and parameters, failure rates dropped without changing component suppliers or PCB materials.

The key lesson: stress introduced at depaneling can outweigh upstream process improvements.

🧩 Practical Engineering Takeaways

Based on shared experience, automotive engineers often agree on:

- Stress control is more critical than cutting speed

- Depaneling must be considered during PCB design

- Process stability matters more than nominal accuracy

- Technology choice should reflect reliability targets

These principles help align depaneling with automotive quality expectations.

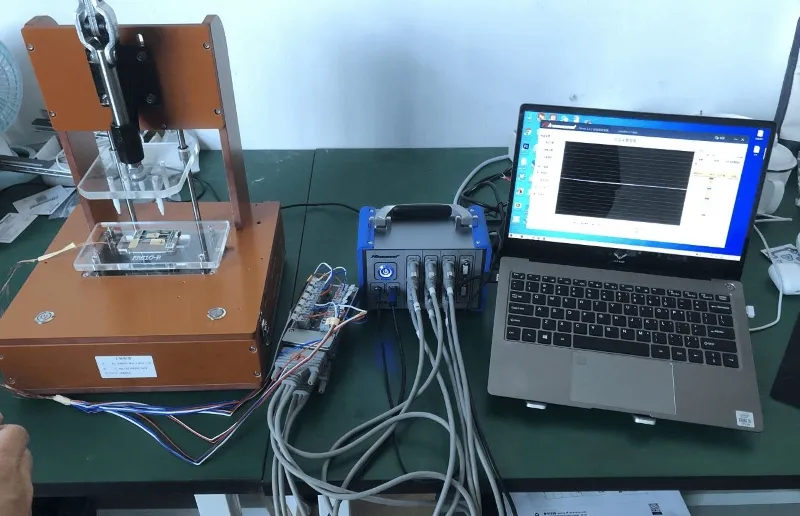

Why Choose Seprays Group?

Seprays Group develops depaneling solutions with a strong focus on industrial quality, durability, and controlled stress behavior for demanding applications such as automotive electronics. Our experience supports manufacturers in selecting and stabilizing depaneling processes under real production conditions.

If you would like to discuss depaneling stress control or automotive SMT requirements, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)