01—The century-old problem of small batches of PCBs: the tyranny of fixtures

Customization fees suck blood: each new board costs more than ¥3000, and 20 orders cost 60,000?

Changing lines is like moving: 4 hours to adjust the machine, to meet the delivery deadline, the production line is shut down, and a penalty is paid

Warehouses become graveyards: piles of fixtures occupy 30 square meters of prime workshops

Until this equipment appeared – Seprays GAM380AT online PCB milling cutter board splitter

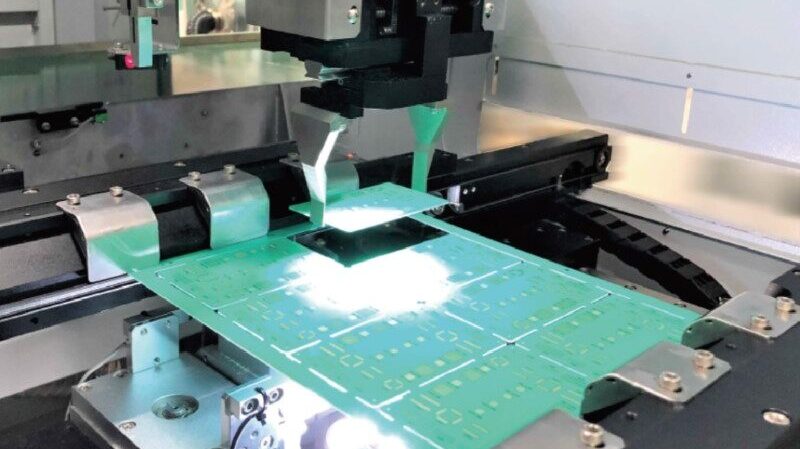

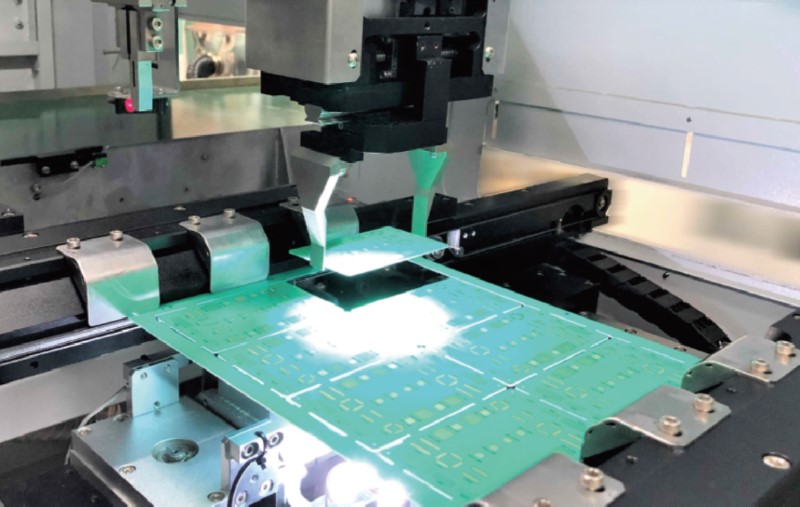

(Actual photo of the GAM380AT machine in action: the bottom milling cutter accurately cuts the PCB board)

02—Three major black technologies kick “fixture hegemony” into the historical trash can

Black technology 1

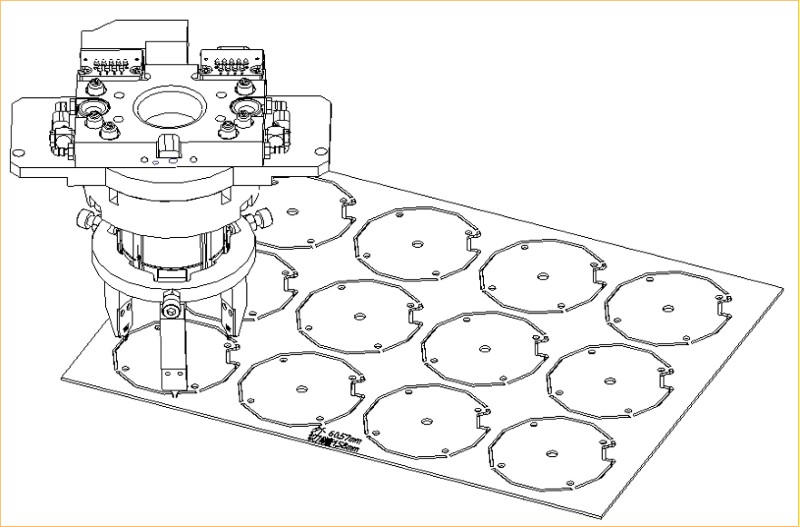

The adaptive pneumatic gripper eliminates the need for permanent fixtures.

Directly grab the edge of any shape PCB and fix it

From small PCB Bluetooth modules to 30cm industrial control motherboards

Actual benefit: A factory cuts 50 samples, saving 150,000 yuan in fixture fees and 280,000 yuan in storage fees per year

Black Technology 2

Changing lines is like watching Douyin | 1 minute to cut and mass produce

Put the PCB board on the track → Scan the code to call the program → Press the start button (no technician is required throughout the process)

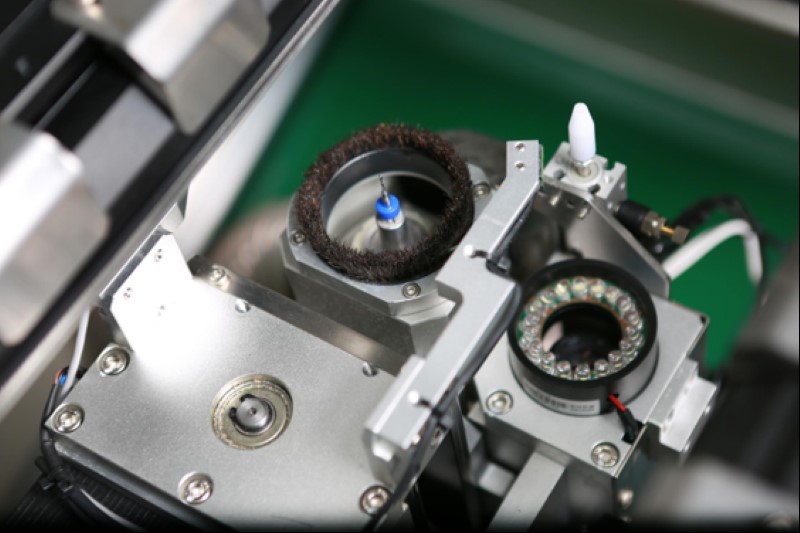

Offline programming nuclear weapon: import Gerber files → visual automatic identification of pads/routing → complex paths generated in 5 minutes

Disruptive scenarios: The morning shift cuts smart watch boards, the afternoon shift cuts 5G base station boards, and the night shift cuts electronic instrument boards – full capacity utilization!

Black Technology 3

Bottom-cut PCB splitter | 0 dust escape

6HP storm vacuum at the bottom + ±0.5mm precision splitter

Confidential report from a military aerospace factory:

“No jig = eliminate the risk of leaks, no need to register jigs for cutting missile control panels”

03—Abacus warning: 90-day payback money printing machine

Investment formula = 1 GAM380AT ≈ 50 sets of fixture costs

Payback period: 15 boards per month → 3 months to eat up the fixture cost

Hidden money printing scene:

✅ Release storage space → Rebuild SMT production line → Increase production capacity by 35%

✅ Transfer of fixture management specialists to process optimization → Reduce labor costs again

04—Screaming solution for PCB board separation

✅ Automotive electronics factory: Cut 20 types of automotive electronic PCB boards, save 60,000 yuan in fixture fees + speed up line change by 4 times!

✅ Medical electronics factory: Put fixtures in the sterilization workshop? Each batch of disinfection is enough to buy a box of milling cutters! Now go directly to the clean room after cutting

✅ Aerospace supplier: ±0.01mm repeatability, cutting PCB boards is like cutting tofu, 200,000/piece boards with zero accidents

.png)