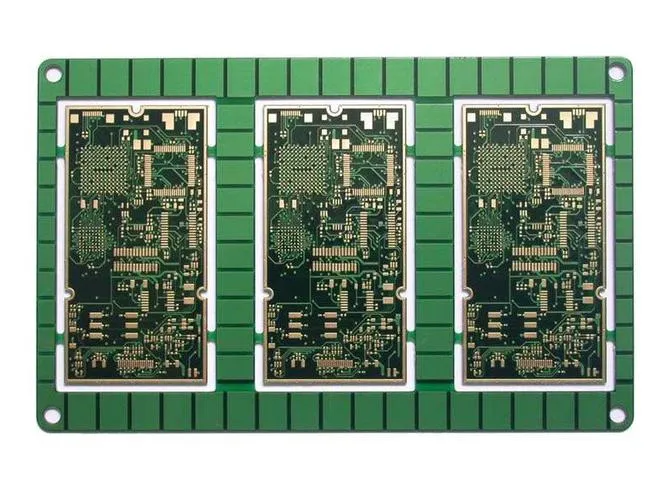

Inline PCB Router Depaneling System in Germany is often discussed among SMT engineers because German manufacturing places exceptional emphasis on precision, documentation, and long-term reliability. In automotive, industrial control, and high-reliability electronics, depaneling is no longer a simple separation step—it is a controlled process that must meet strict quality and traceability expectations. This article summarizes lessons shared by engineers working within German SMT environments.

🏭 Precision Expectations — Beyond Nominal Accuracy

In German SMT lines, accuracy is evaluated over extended production periods rather than during initial acceptance tests. Engineers frequently point out that a system capable of ±0.05 mm accuracy on day one must maintain that level after months of continuous operation.

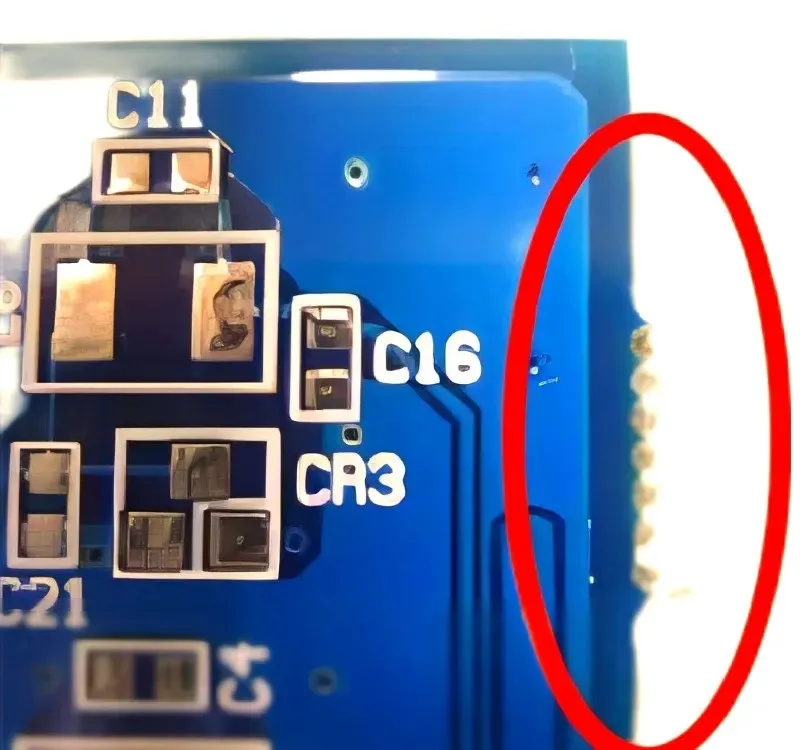

Common challenges include:

- Gradual axis drift under 24/7 operation

- Tool wear is affecting edge quality

- Variation caused by panel thickness tolerance

As a result, inline router systems are often assessed based on structural rigidity, thermal stability, and motion control consistency rather than advertised speed.

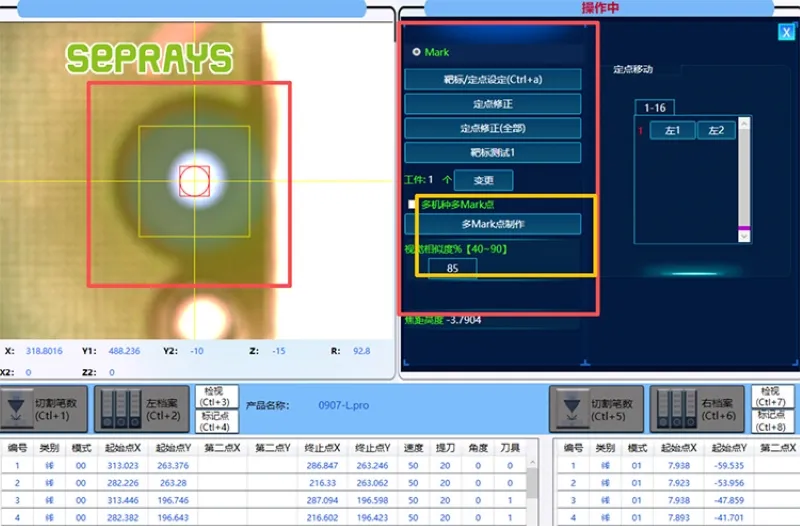

🔍 Traceability — A Non-Negotiable Requirement

Traceability plays a central role in German electronics manufacturing. Depaneling systems are expected to integrate seamlessly with MES and line control systems.

Key traceability requirements discussed by engineers:

- Board-level identification and data logging

- Recording of cutting parameters per panel

- Error and alarm history linked to production batches

Without reliable traceability, downstream quality analysis and compliance reporting become difficult, increasing operational risk.

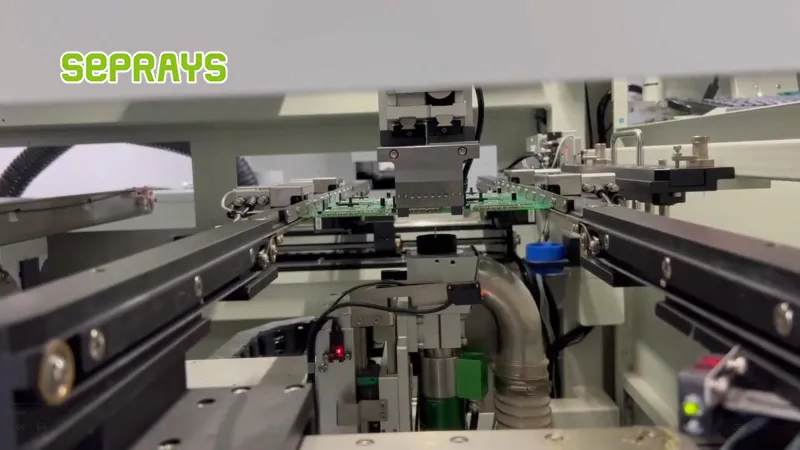

⚙️ Inline Integration — Stability Over Throughput

Inline depaneling is valued for automation, but German factories prioritize stability over maximum throughput.

Pain points reported include:

- Mismatch between the depaneling cycle time and the upstream SMT takt time

- Sensitivity to panel warpage during automatic loading

- Inconsistent clamping is affecting cut repeatability

Solutions often involve precise panel support design, controlled routing paths, and synchronized communication with upstream and downstream equipment.

📉 Cost Analysis — The Price of Instability

While inline systems represent a higher initial investment, engineers highlight that instability is far more expensive over time.

Hidden costs observed in production:

- Scrap from micro-cracks discovered during reliability testing

- Rework caused by inconsistent edge quality

- Downtime due to frequent recalibration

- Audit risks from incomplete traceability records

Several German SMT lines reported that improving depaneling stability reduced overall quality-related costs, even when equipment investment increased.

🌍 Case Observations from German SMT Lines

- Automotive electronics: Focus on stress control and documented process stability

- Industrial automation: Emphasis on long-term durability and spare part availability

- High-reliability assemblies: Preference for conservative cutting parameters and full data logging

Across applications, depaneling is treated as a quality-critical process rather than a secondary operation.

🧩 Engineering Takeaways

From shared experience, German engineers often agree on the following:

- Precision must be sustained, not demonstrated once

- Traceability is as important as cutting quality

- Rigid machine design supports long-term accuracy

- Inline automation requires controlled panel handling

- Process documentation reduces audit and quality risks

These principles guide equipment evaluation and process planning.

Why Choose Seprays Group?

Seprays Group designs inline router depaneling solutions with a strong focus on industrial durability, precision stability, and traceability-ready architecture. Our systems are developed to support long-term operation in demanding SMT environments while maintaining consistent cutting quality.

If you would like to discuss inline depaneling requirements or traceability integration, please contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)