Multi-blade PCB depaneling machines are transforming how electronics manufacturers approach PCB separation.

With rising production demands, low-stress and high-speed cutting is no longer optional — it’s essential.

The right depaneling solution boosts yield, reduces damage, and accelerates throughput.

⚙️ Why Traditional Methods Are Falling Behind

Manual depaneling or single-blade machines often slow production and increase risk.

Common challenges include:

- Stress-induced microcracks

- Burrs and uneven edges

- Dust contamination

- Labor-intensive handling

These issues reduce yield, increase rework, and hurt overall efficiency.

A multi-blade approach changes the game, offering faster, cleaner, and more reliable results.

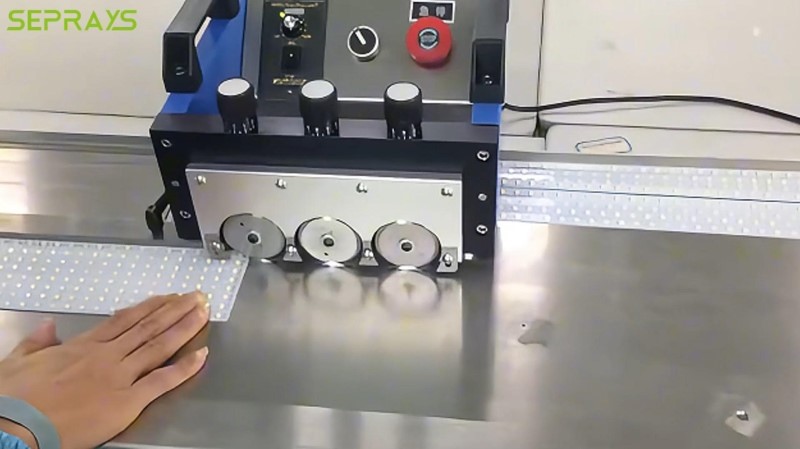

🚀 How Multi-Blade PCB Depaneling Machines Work

Unlike single-blade systems, multi-blade machines use several cutting heads simultaneously.

This enables:

- Multiple boards are cut at once

- Balanced cutting forces for low stress

- Smooth, mirror-like edges

By distributing the load across several blades, vibration is minimized, and components remain safe.

Production speed increases without compromising precision.

🎯 High-Speed Cutting for Modern Demands

Modern PCB lines require both speed and accuracy.

Multi-blade depanelers achieve this through:

- Optimized spindle rotation

- Intelligent feed rate control

- Precision synchronization between blades

Faster cycles mean higher throughput, while maintaining low stress prevents board damage.

🧹 Clean and Dust-Free Operation

Debris is a hidden enemy in PCB production.

Dust can contaminate components, reduce spindle life, and degrade cutting accuracy.

Multi-blade systems often integrate:

- Advanced vacuum extraction

- Enclosed cutting chambers

- Automatic debris removal

This keeps both the machine and PCB clean, extending service life and ensuring consistent quality.

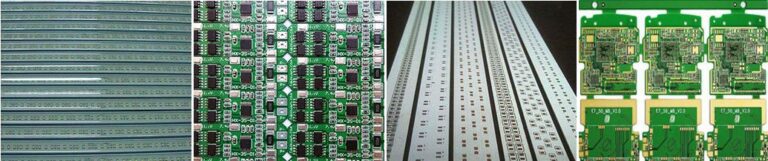

🔧 Versatility and Adaptability

Not all PCBs are the same. Some boards are thin, some thick, some fragile, and others rigid.

Multi-blade depaneling machines are designed for flexibility:

- Adjustable blade spacing

- Adaptable cutting depth

- Support for various board sizes and layouts

This versatility makes them suitable for automotive, medical, consumer electronics, telecom, and LED boards.

⚡ Reducing Labor and Manual Errors

Automation reduces reliance on skilled operators.

Multi-blade systems can load, cut, and unload boards automatically.

Fewer manual interventions mean fewer mistakes, faster setup, and higher line efficiency.

Operators can focus on quality control and other high-value tasks rather than repetitive cutting.

🌿 Low-Stress Design Protects Components

Mechanical stress is a major cause of PCB defects.

By using multiple cutting heads and optimized motion control, multi-blade depanelers:

- Minimize stress on solder joints

- Prevent micro-cracks in sensitive areas

- Maintain edge integrity for surface-mount components

This leads to better yields and more reliable end products.

🧩 Smart Integration into Production Lines

Modern electronics manufacturing demands seamless flow.

Multi-blade depaneling machines are often inline-ready, integrating with SMT lines, conveyors, and robotic systems.

This enables continuous production with minimal downtime, supporting the demands of Industry 4.0 environments.

⭐ Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- ISO9001, ISO14001, and ISO45001 certified.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

- Global service network in 31+ countries.

We combine advanced engineering with reliable service support, helping manufacturers achieve higher yields and smoother production.

If your production line is ready to upgrade, Seprays Group provides reliable, high-quality solutions.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)