PCB Depaneling Machine Price Comparison is often the first question raised when automotive electronics manufacturers evaluate new equipment. In high-reliability sectors such as ADAS, power control units, and battery management systems, price alone rarely tells the full story. This article shares practical observations from production floors, focusing on cost structure, long-term value, and decision pitfalls—rather than marketing claims.

⚙️ Understanding the Real Cost Behind the Price Tag

When comparing depaneling machines, buyers typically encounter a wide price range, ranging from manual solutions to fully automated in-line systems. However, the purchase price typically accounts for only part of the total cost.

Key cost components include:

- Initial machine price

- Tooling and consumables (router bits, blades, optics)

- Maintenance and downtime

- Scrap and yield loss due to stress or burrs

In automotive electronics, even small increases in defect rates can outweigh savings from a lower upfront price.

🧩 Common Buyer Pain Points in Automotive Applications

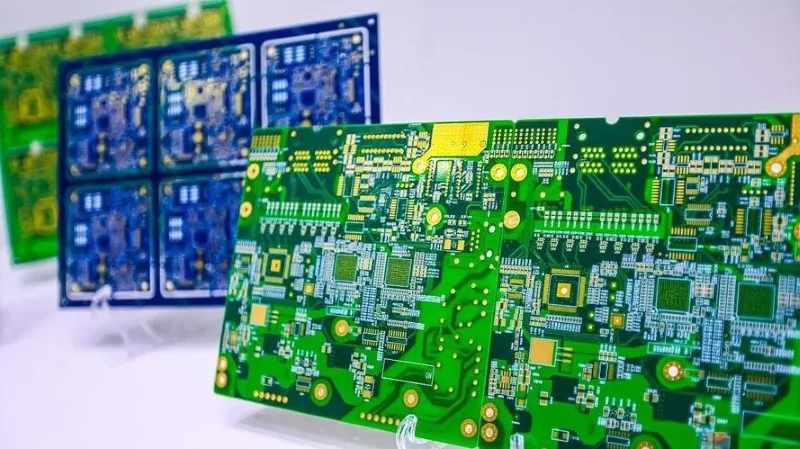

Automotive PCBs are thicker, heavier, and often populated with sensitive components. Buyers frequently report challenges such as:

- Micro-cracks caused by mechanical stress

- Inconsistent cut quality across multi-layer boards

- Equipment wear under 24/7 production schedules

A lower-priced machine that struggles with durability or consistency can quickly become a bottleneck.

🔍 Technology Comparison and Cost Implications

Different depaneling technologies come with distinct cost profiles:

- V-Cut systems

Lower equipment cost, but limited design flexibility and higher stress—often unsuitable for complex automotive layouts. - Router depaneling machines

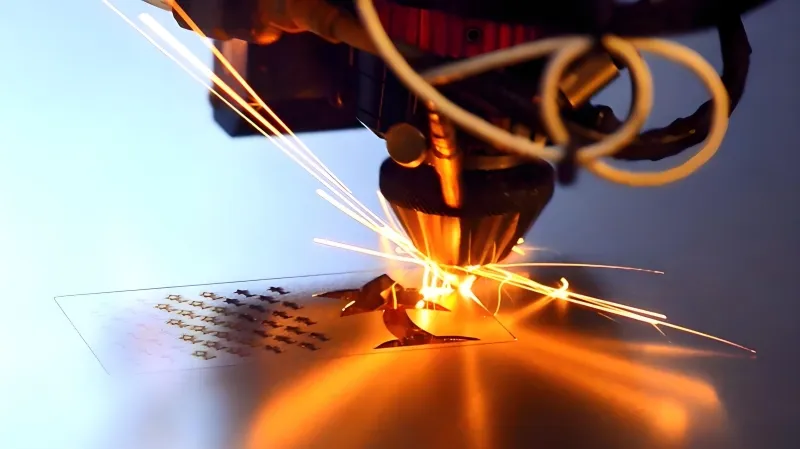

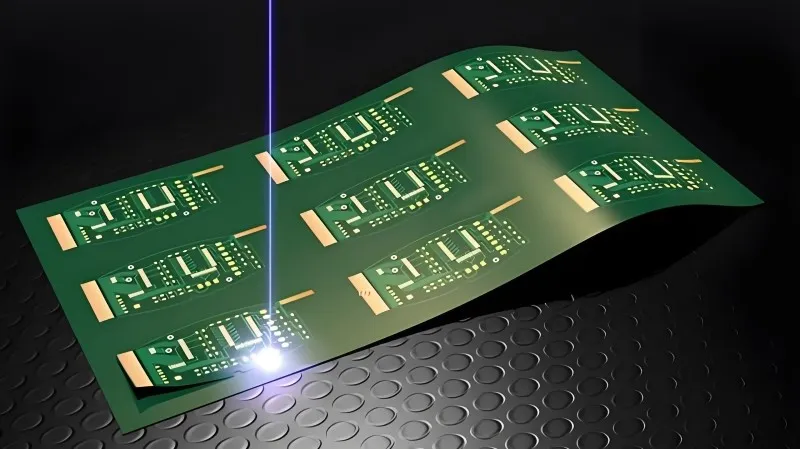

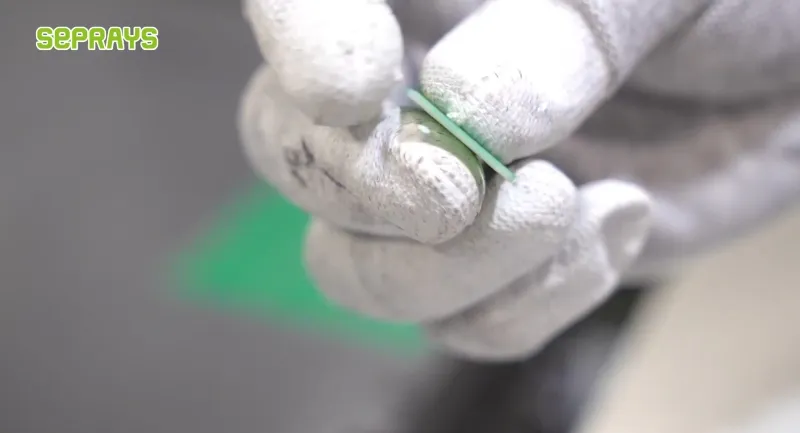

Mid-range investment with a good balance between flexibility and quality. Tool wear and dust management add to operating costs. - Laser depaneling systems

Higher initial price, but minimal mechanical stress and lower consumable costs over time—attractive for high-value automotive boards.

Price comparison should always align with board design, volume, and reliability requirements.

📊 Case Insight: Cost vs. Reliability in Practice

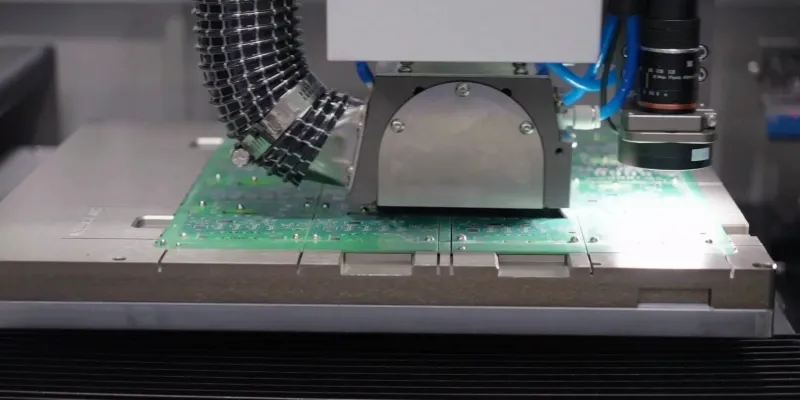

One Tier-2 automotive supplier replaced a low-cost router with a higher-spec automated system after recurring field failures were traced back to depaneling stress. Although the new machine increased capital expenditure, overall warranty and rework costs dropped significantly within the first year.

This illustrates a common pattern: in automotive electronics, cost optimization often stems from risk reduction rather than the price of equipment alone.

🛠️ Choosing a Solution That Balances Price and Durability

Instead of asking “Which machine is cheapest?”, experienced engineers tend to ask:

- Can the machine maintain precision over years of operation?

- Is stress control validated for automotive standards?

- How predictable are maintenance and spare part costs?

A well-matched depaneling solution supports stable production and predictable long-term costs.

🌍 Aligning with Global Automotive Manufacturing Trends

Across EMS and OEM sectors, global manufacturers increasingly favor standardized, durable depaneling platforms that can be replicated across plants. This approach simplifies training, quality control, and cost forecasting—key considerations in a global supply chain.

✅ Why Choose Seprays Group?

Seprays Group focuses on industrial-grade PCB depaneling solutions designed for durability, consistency, and automotive-level quality requirements. Our experience across multiple depaneling technologies allows us to support engineers in selecting solutions based on real production needs—not just price comparisons.

If you need further discussion or would like to explore options for your specific application, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)