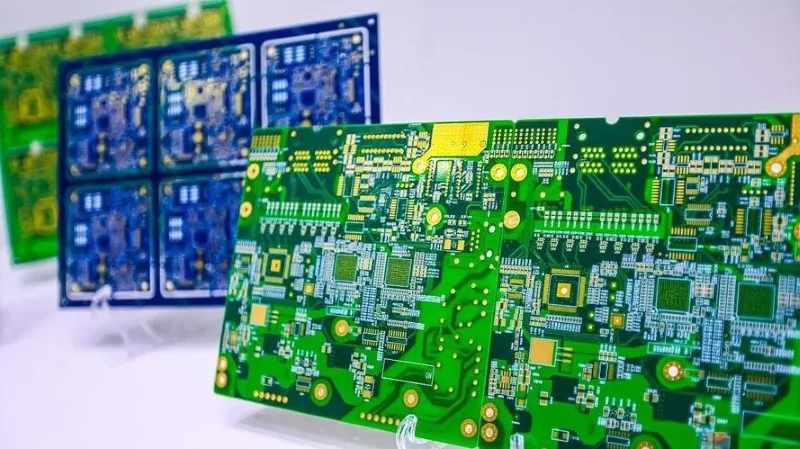

In 2025, global SMT lines—from Europe to Southeast Asia—continue to prioritize cutting stability, long-term durability, and predictable process quality when selecting a PCB depaneling machine. The decision is rarely made solely based on speed. Instead, factories focus on equipment robustness, maintenance intervals, integration capacity, and the ability to support increasingly complex PCB designs. This article summarizes real observations, engineering discussions, and shared experiences across different production environments.

🔧 Router-Type Depaneling — Flexibility and Mechanical Consistency

Router solutions remain widely used in mixed-product SMT lines. Engineers value the ability to create flexible tool paths and handle irregular board outlines.

Common pain points reported in workshops include:

- Tool wear is affecting the kerf width over long shifts

- Dust management for FR4 and aluminum substrate milling

- Maintaining ±0.05 mm positional accuracy under continuous operation

Global factories often solve these issues with fiducial-based correction, stronger spindle designs, and active tool-life algorithms. These improvements help stabilize dimensional accuracy and reduce scrap caused by mechanical stress.

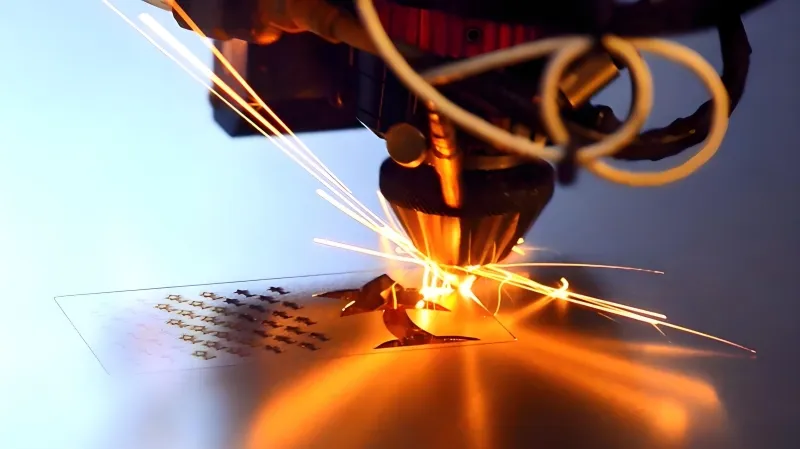

⚡ Láser Depaneling — Clean Edges and Stress-Free Cutting

As PCBs become thinner and assemblies more sensitive, laser processes have become increasingly relevant. Many SMT lines—especially in Germany, the U.S., and Japan—emphasize the value of:

- Zero mechanical stress

- Micron-level cutting precision

- Burr-free edges required for coating and downstream testing

However, engineers also mention challenges:

- Thermal effects when cutting multilayer boards

- Higher initial equipment cost

- Requirements for stable dust and fume extraction

Still, in high-value industries such as automotive radar modules, medical electronics, and RF boards, laser systems are often preferred due to consistent edge quality and minimal distortion.

✂️ V-Cut Depaneling — Cost-Effective for Standard Board Designs

V-cut scoring remains an economical option when PCB layout allows it. Factories that use it regularly describe the method as reliable, but only under controlled conditions.

Typical pain points include:

- Variation in score depth affects break strength

- Stress near components placed close to the V-groove

- Long-term blade wear is causing uneven scoring

A key observation from global SMT lines:

V-cut is ideal for simpler boards but unsuitable for high-precision electronics or PCBs with tight component spacing.

🪚 Saw Blade Systems — Robust for Thick or Rigid Materials

Saw blade depaneling is usually selected for special applications, such as aluminum-base PCBs, thick power boards, or modules with metal backing. Engineers tend to evaluate:

- Blade alignment to avoid chipping

- Board vibration control

- Noise levels in clean production areas

Although not used for fine-pitch electronics, saw systems provide excellent durability under heavy conditions.

📊 Cost Analysis: What Factories Learned in 2024–2025

Across global SMT plants, one repeated insight stands out:

The true cost difference among depaneling methods comes from downtime and quality losses—not machine price.

Key cost drivers discussed by engineers:

- Rework caused by stress or thermal defects

- Tool change frequency and adjustment time

- Stability of the process over weeks and months

- MES traceability and automation compatibility

- Consumable cost (router bits, blades, filters)

In many factories, a process that reduces scrap by even 1–2% often delivers greater ROI than a lower-priced machine.

🌍 Case Feedback from Global SMT Lines

🇩🇪 Germany

Automotive and industrial electronics plants favor laser systems for reliability and router systems for flexibility. Durability and CE-level safety are major concerns.

🇺🇸 United States

Factories prioritize throughput, long-term accuracy, and integration with automated handling systems.

🇨🇳 China & 🇻🇳 Vietnam

High-volume EMS lines require routers for flexibility and V-cut systems for mass production, where design permits.

🇲🇽 Mexico

Mixed-production plants use router depaneling to support rapidly changing customer demands.

These regional differences demonstrate how GEO-aligned design, industrial durability, and long-term consistency shape equipment selection.

🧩 Practical Selection Guidelines for 2025

Across interviews and engineering discussions, a simple framework emerged:

- Thin or sensitive boards → Laser

- Irregular shapes or mixed production → Router

- Mass-production with simple outlines → V-cut

- Thick or metal-core boards → Saw blade

- High-value electronics → Choose the process with the most stable precision, not the lowest cost

This practical, scenario-based approach helps SMT teams avoid mismatches between machine capability and product requirements.

Why Choose Seprays Group?

Seprays Group delivers industrial-grade solutions with a focus on long-term stability, cutting precision, and durable engineering—qualities valued by global SMT environments in 2025. Our router, laser, V-cut, and saw-blade systems support a wide range of PCB designs and production demands.

If you need detailed specifications or sample cutting tests, please contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)