Descripción

| Modelo | GAM300AT |

|---|---|

| Válido de corte tamaño | 350*300 mm |

| Método de carga | Seguimiento de la entrega |

| Descarga método de | Seguimiento de la entrega |

| La dirección del movimiento | De izquierda a derecha o de derecha a izquierda |

| La función de corte | La interpolación de la línea recta, en forma de L, en forma de U, Círculo, Arco |

| Precisión de repetición | ±0.01 mm |

| Precisión de corte | ±0,05 mm |

| Max velocidad de movimiento | XY: 1000mm/s, Z: 800 mm/seg. |

| Velocidad del husillo | MAX: 60000rpm |

| Herramienta de tipo de cambio | Automático de cambio de herramienta |

| La velocidad de corte | 1-100mm/s |

| Sistema operativo | Windows10 |

| The program teaching method | Intuitiva de la enseñanza por parte del CCD color de la imagen de entrada |

| Método de Control de la | Precisión multi-eje del sistema de control de |

| Eje XYZ en el modo de conducción | Motor Servo de la CA |

| Tamaño de la herramienta de fresado | 0.8-3.0 mm |

| Voltaje/Potencia requerida | AC220V 50/60Hz 4KW de una Sola fase |

| Presión neumática requisito | 0.6 MPa, 75L/min |

| Dimensiones(W*D*H) | 930*1101*1689mm |

| Peso | 550kg |

| Colector de polvo | TS300L |

Introducción De Producto

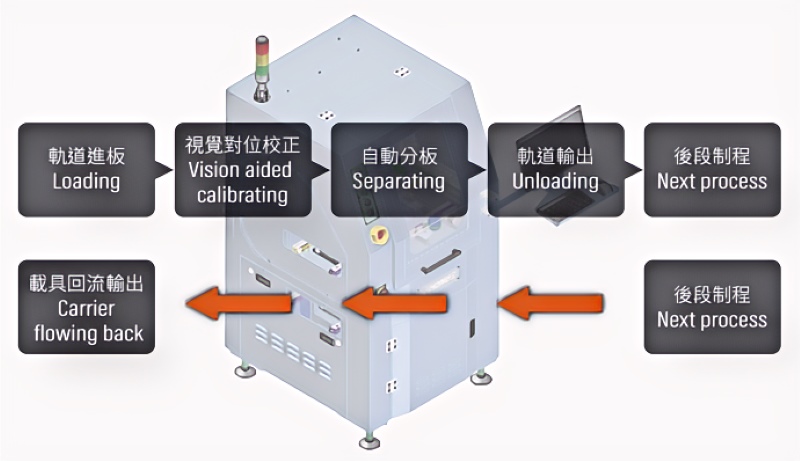

Suitable for in-line SMT full-carrier processes, it features a carrier reflow track for complete line automation.

Equipped with a high-speed spindle, it reduces cutting stress and achieves high precision. It also comes standard with an automatic tool changer for automated operation.

A powerful vacuum cleaner with dust detection and alarm ensures effective dust collection.

El GAM300AT PCB router is a compact, high-performance depaneling system built for seamless integration into SMT production lines using carriers throughout the manufacturing process. Designed specifically for board edge-free technologies, power adapters, and compact PCB designs, the GAM300AT PCB router helps reduce manual labor and increase production efficiency.

With a high-speed CCD vision alignment systemel GAM300AT PCB router ensures accurate and repeatable cutting by detecting offsets and automatically adjusting the cutting path. Its ESD-protected high-speed spindle features an auto tool-change function, effectively minimizing the risk of PCBA damage due to static.

This machine is optimized for modern electronics manufacturing environments where space-saving, automation, and precision are critical. Optional features include a barcode reader y custom MES integration for enhanced traceability and workflow automation.

Choose the GAM300AT PCB routers for smart, safe, and scalable PCB routing.

Características

Patented floating brush

- The patented floating brush reduces stress during cutting.

- Allows the milling cutter to be used in multiple stages, extending its lifespan.

Maintenance reminder

- Settable maintenance schedule.

- Dust filter bag cleaning schedule.

- Regular reminders for operator maintenance.

High uptime

- With over 32 years of independent software development, the splitter utilizes stable and reliable software, eliminating bugs that could cause board failure.

Exclusive Features

- The depaneling machine features a one-piece welded design for stability and high strength.

- Made of cast aluminum, it resists oxidation, deformation, and shifting, ensuring a long lifespan and guaranteed precision.

Dust collection eliminates dust hazards

- Utilizes a high-power dust collector.

- HEPA-rated dust filtration.

- Equipped with a negative pressure detector to continuously monitor dust collection status.

- Equipped with a floating brush (patent number ZL201721620742.X) to enhance dust collection efficiency.

Centralized Control System Management

- Optional central control system: Centralized management and real-time monitoring via network IP.

- Remote device management: Remote monitoring via mobile app.

Application Examples

Suitable for edgeless board processes, power adapters, mobile phones, and other industries

.png)

Valoraciones

No hay valoraciones aún.