Descripción

| Modelo | ZM30-LT |

|---|---|

| Tamaño del equipo | L:1250M M、W:500 MM、H:1200MM |

| El equipo de la tensión de | 220V |

| El poder | 3000w/H |

| Máx longitud de la junta | 300 MM(más el tamaño productos sin auxiliar de empuje de material) |

| Ancho máximo | 250 MM(se puede personalizar widera) |

| El tamaño de disco | 3x40x80 |

| Thinkness | 0.5–2.5 MM |

| Velocidad | ajustable |

| Rango ajustable de cuchillo eje | 5MM(arriba y abajo ajustable) |

| Soporte de personalización | puede ser personalizado de acuerdo a los parámetros y requisitos establecidos por los clientes |

Introducción De Producto

Online fully automatic panel splitter, effective cutting size: 150mm-300mm

Panel splitter equipment: The spacing between each split product must be greater than 8mm.

A fully automatic panel splitter is suitable for equidistant and non-equidistant product splitting.g

The machine can be changed according to the width of the product and the spacing between each split. It

Users can select the electrical control part through the human-machine interface, making it convenient to open or shield.

Engineers equip the equipment with a human-machine interface and protect it with a closed or acrylic cover to ensure safety and prevent damage.

Operators need to place the floor-standing structure in a specific work area for it to participate in the operation.

The design uses a square welded frame, and technicians apply powder coating and paint to the surface of the sheet metal sealing plate.

Engineers rust-proof the mechanical structure through electroplating or anode sandblasting, and they manufacture all components using 45# steel plate, A3 steel plate, or national standard aluminum surfaces.

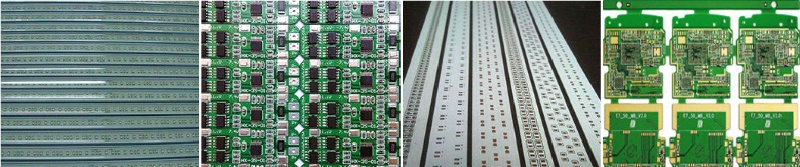

Aplicación De Casos

El ZM30-LT depaneler is an advanced, fully automated solution designed to streamline the depaneling process from start to finish. From automatic feeding to precise cutting and smooth discharging, this intelligent system minimizes manual handling while boosting production efficiency and consistency.

Equipado con precision positioning technologyel ZM30-LT depaneler ensures accurate cuts without damaging delicate PCBAs, safeguarding product quality throughout the operation. Its flexible material handling system—featuring suction cups and belt conveyors—easily adapts to varying sizes and shapes of circuit boards.

An integrated waste management system instantly collects cutting debris, keeping the work area clean and optimizing production flow. Designed for continuous cycle operation, this depaneler is the ideal solution for high-volume, uninterrupted manufacturing environments.

.png)

Valoraciones

No hay valoraciones aún.