PCB materials suitable for laser depaneling are not unlimited, and laser is not always the right answer. In real SMT production, laser depaneling performs extremely well for specific materials and use cases, while being less effective or inefficient for others.

So instead of asking “Can laser cut this PCB?”, engineers usually ask a more practical question:

“Is laser depaneling the most stable and cost-effective option for this material?”

🔍 The Short Answer First

Laser depaneling is best suited for PCB materials that are:

- Thin

- Stress-sensitive

- High value

- Difficult to route mechanically

If your PCB falls into that category, a laser often solves problems that routing or V-cut cannot.

⚙️ PCB Materials That Work Well with Laser Depaneling

From real production experience, these materials consistently perform well:

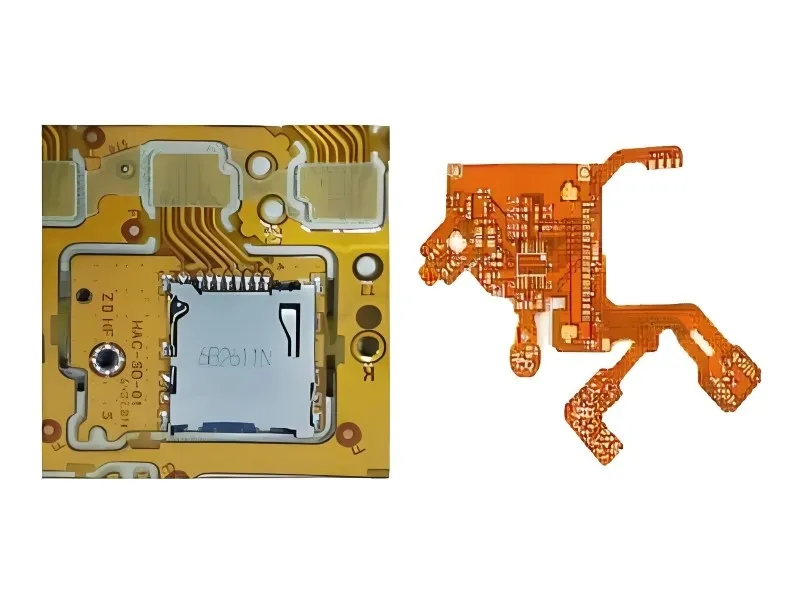

🟢 FPC and Rigid-Flex PCBs

- Polyimide absorbs laser energy efficiently.

- No mechanical stress on fragile copper traces

- Ideal for compact, irregular outlines

Laser depaneling is often the default choice here.

🟢 Thin FR4 (Standard & High-Tg)

- Especially suitable for dense layouts

- Useful when components are close to the board edge

- Eliminates routing vibration risks

Most issues only appear when boards become thick or contain a lot of copper.

🟢 BT Resin and High-Precision Substrates

- Common in automotive and industrial electronics

- Benefit from clean edges and tight tolerances

These materials are often chosen because laser depaneling is available.

⚠️ Materials That Need Careful Evaluation

Laser depaneling is not ideal for everything:

- Thick FR4 with high glass content cuts slowly

- Heavy copper layers spread heat

- Low-grade laminates may carbonize

Laser can still work—but only after trials and cost checks. In some cases, routing is simply more practical.

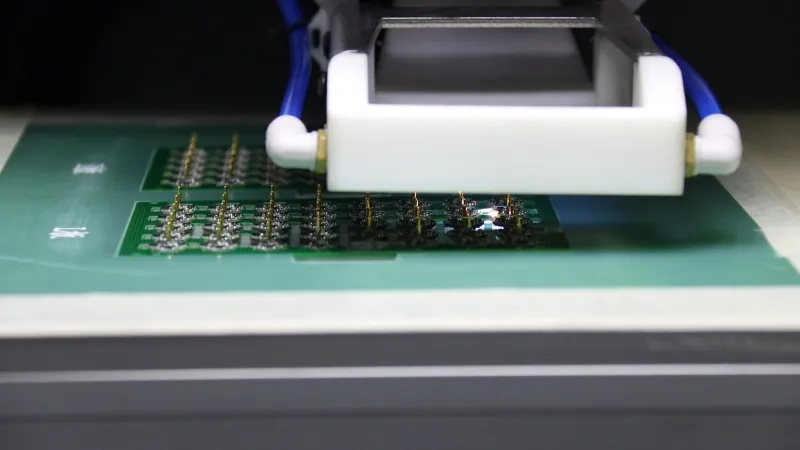

💡 Why Engineers Switch to Laser Depaneling

Most teams don’t choose laser for speed. They choose it to fix problems like:

- Cracked MLCCs after routing

- Burrs and fiber pull-out on edges

- Very tight component-to-edge spacing

- Complex board shapes with frequent design changes

Laser removes mechanical stress entirely, which changes the failure profile.

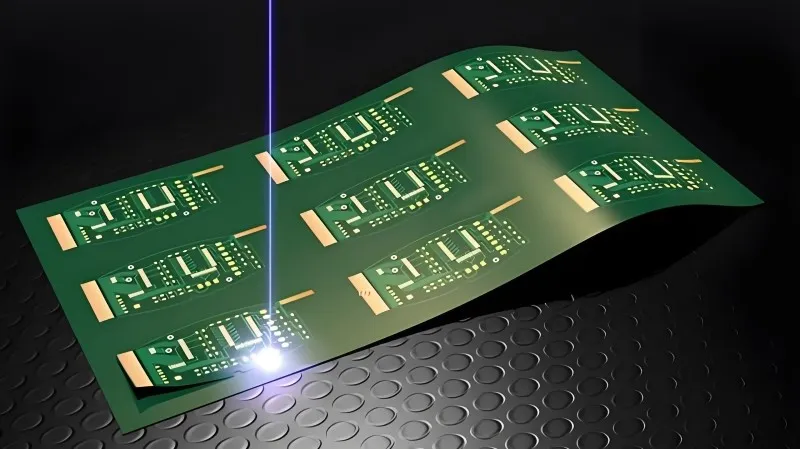

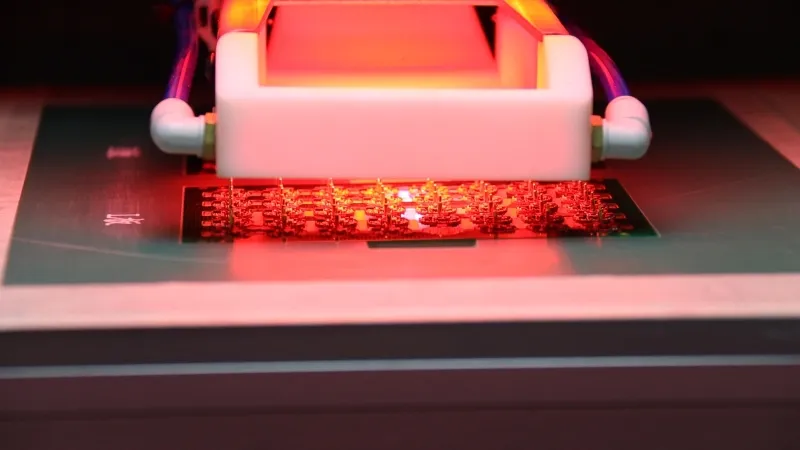

✨ What Laser Depaneling Does Better (Seprays In Practice)

From factory feedback, these advantages matter most:

- Ultra-high precision (< 2 μm)

- Zero mechanical stress or vibration

- Very narrow kerf (< 25 μm) → more usable PCB area

- Free-form cutting without design constraints

- No cutters, blades, or molds → no consumables

- Clean, stain-free edges

- Fast for thin and small boards

For high-value PCBAs, these benefits often outweigh throughput limits.

📉 Cost Reality: Expensive or Just Different?

Laser systems cost more upfront—but many teams find:

- Scrap rate drops

- Tooling cost disappears

- Edge-related rework is eliminated

- Reliability improves

For automotive, medical, or industrial products, laser depaneling often reduces total cost, not increases it.

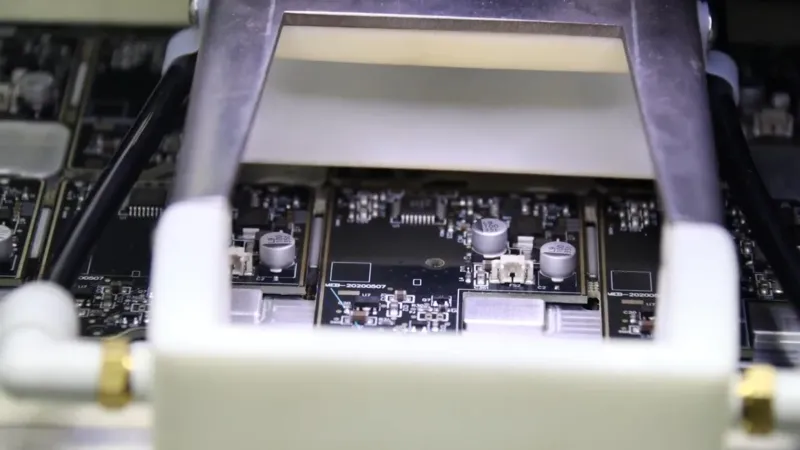

🏭 Case Insight: Automotive Electronics (BYD Project)

In an automotive electronics project near BYD, thin FR4 control boards failed reliability tests after mechanical routing. The issue wasn’t layout—it was depaneling stress.

After introducing Seprays-supported laser depaneling for those boards:

- Cracks disappeared

- Edge quality stabilized

- Thermal cycling passed consistently

The laser was applied selectively—not across the whole line.

🛠️ Practical Advice from the Field

Before choosing laser depaneling:

- Look at the material first, not the machine specs

- Segment products by stress sensitivity

- Compare lifecycle cost, not just CAPEX

- Avoid forcing one depaneling method on all boards

Laser works best when used intentionally, not automatically.

💬 Why Choose Seprays Group?

Seprays Group provides laser depaneling solutions with a clear focus:

Use laser where it actually solves problems—and avoid it where it doesn’t.

We help manufacturers match PCB materials, reliability targets, and depaneling methods based on real production data.

If you want to evaluate whether laser depaneling fits your PCB material or product, please feel free to contact us.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)