How to Save Cost in PCB Cutting is becoming a key discussion topic in European electronics manufacturing. German and French automotive, industrial control, and medical device producers frequently share the same concern:

“We need lower production cost, but we cannot afford dimensional deviation, stress cracks, or burrs caused during PCB depaneling.”

Precision requirements keep rising, while budgets are carefully evaluated under long-term operational cost rather than just machine purchase price. This article explores practical and experience-based approaches to balance cost and precision in PCB cutting.

🏭 Why PCB Cutting Accuracy Matters in European Manufacturing

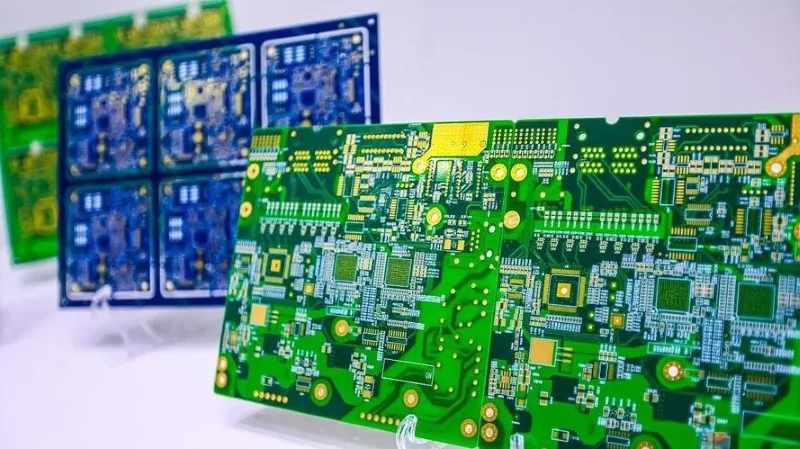

High-end PCBs used in robotics, railway electronics, charging systems, aerospace, and power management are subject to long lifetime expectations and strict conformity rules enforced by standards such as:

- IPC-A-610 Class 3

- IATF 16949 / ISO 26262 (Automotive)

- EN 60601-1 (Medical Electronics)

Even a 0.1–0.2 mm routing deviation may cause misalignment during assembly or long-term reliability failures. German and French engineers often highlight edge reliability, fiber structure, and copper integrity as mandatory criteria.

🛠 Common Cost Pain Points in PCB Depaneling

Manufacturers regularly report these challenges:

| Pain Point | Impact |

|---|---|

| High tool wear (router bits/saw blades) | Repeated replacement + production interruption |

| Machine downtime & manual adjustments | Lower throughput + overtime labor |

| Dust contamination or fiber burrs | Optical/RF defect risk, rework cost |

| Stress-related PCB cracks | Scrap cost + warranty exposure |

| Inefficient panel utilization | Higher PCB material expense |

Many factories discover that the cheapest depaneling method becomes the most expensive over 12–24 months of production.

📉 Cost Structure Analysis: Where Savings Truly Come From?

Cost does not only come from equipment price; understanding operational cost (OPEX) is essential:

| Cost Category | Typical Savings Strategy |

|---|---|

| Tool consumption | Longer bit lifespan, optimized spindle + speed settings |

| Labor & supervision | Automated fiducial alignment + MES connectivity |

| Scrap & hidden quality cost | Low-stress cutting + stable repeatability |

| Energy consumption | Efficient servo axes + vacuum system optimization |

| Material utilization | Panel nesting strategy improves yield |

Companies that track cost per panel, not only cost per machine, achieve better long-term budget visibility.

⚙ Cutting Technology Comparison (Cost Perspective)

| Cutting Method | Stress Level | Accuracy | Cost Trend | Suitable For |

|---|---|---|---|---|

| Manual / V-Cut | High | Low–Medium | € (Low upfront) | Simple consumer PCBs |

| Punching Tool | Medium | High | €€ (Tool maintenance) | High volume, same design |

| Saw Blade | Medium | High | €€ | Thick copper / power boards |

| Router Cutting | Very Low | Very High | €€–€€€ | Automotive, aerospace, medical |

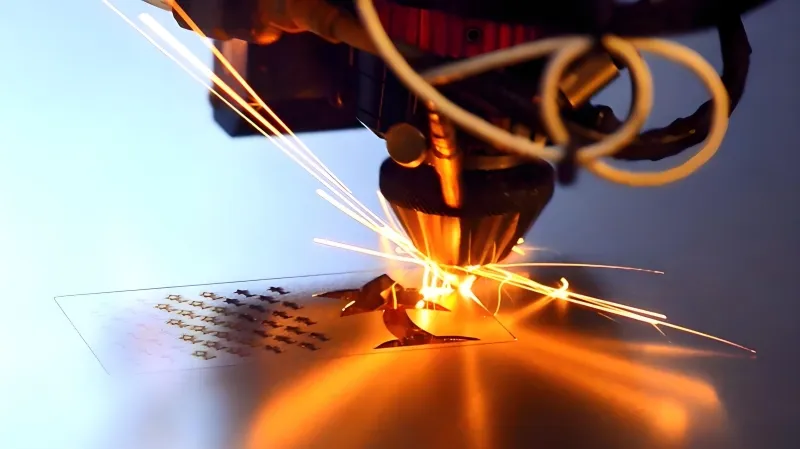

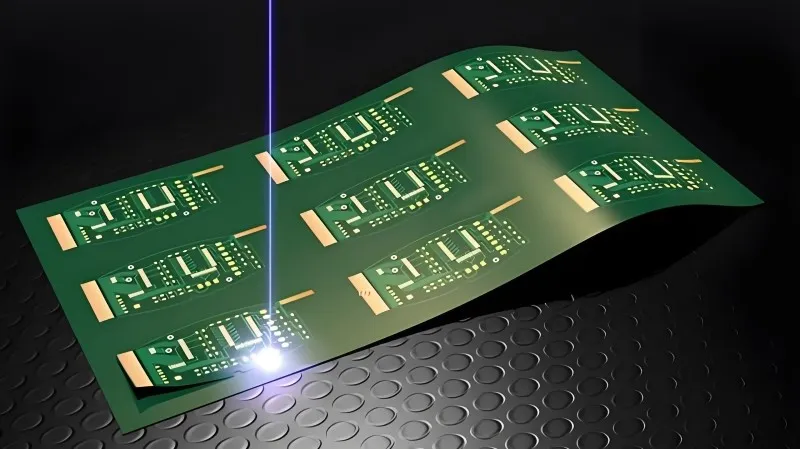

| Laser Cutting | Zero Stress | Ultra-High | €€€–€€€€ | RF, flexible, thin materials |

Observation from EU factories:

Router systems represent the best ratio of precision vs. operational cost in most industrial and automotive applications.

🧪 Case Example (Germany – Industrial Automation PCB)

A Bavarian motion-control manufacturer compared manual V-cut and high-precision router cutting.

| Before (V-Cut) | After (Router Cutting) |

|---|---|

| Scrap rate: 3.2% | Scrap rate: 0.45% |

| Unplanned rework due to burrs | No burr rework required |

| Operator dependency high | Fully automated, MES logged |

| Frequent copper edge cracking | No stress cracks reported |

Return on investment achieved within 11 months.

🔍 Practical Ways to Reduce PCB Cutting Cost Without Losing Accuracy

🔧 1. Use optimized cutting parameters

Feed rate, spindle speed, and step-down depth directly affect routing quality and tool wear.

🌀 2. Keep dust extraction and vacuum filtration efficient

Cleaner airflow extends bit life and reduces contamination.

📏 3. Apply panel design for depaneling (DFD)

Reducing unnecessary travel paths and improving fixture stability saves time.

🔩 4. Choose long-life router bits / diamond-coated tools

Up to 4–6× longer lifespan in high-Tg or thick copper PCBs.

🤖 5. Integrate machine vision + automatic fiducial correction

Helps maintain accuracy despite PCB shrinkage during reflow.

🧰 When Does Laser Make Financial Sense?

Laser depaneling can be worth the investment when:

✔ PCB includes flex, hybrid, ceramic, and RF layers

✔ Edge quality must be fiber-free

✔ Ultra-small form factor or tight nesting required

However, for many industrial European applications, router cutting remains more economical.

🏁 Why Choose Seprays Group?

Seprays provides PCB depaneling solutions developed with a focus on industrial European standards:

🔧 High accuracy and low-stress router/laser systems

🛡 CE-compliant, suitable for automotive, railway, aerospace

📉 Reduced tooling cost with extended router bit lifespan

📊 MES/traceability, stable for continuous 24/7 production

🌍 Experience deployed in Germany, France, Italy, and the Netherlands

If you would like a process evaluation with cost-per-panel calculation, feel free to contact us.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)