最新の製品

約Seprays

台湾に設立された1993年, Seprays 主 技術のR&Dとイノベーション. に 2002ので、 支店を開設し東莞 (クリスマス、イースターに改組 子会社2013年)全責任者 研究開発、生産、販売、販売後の技術トレーニングサービスを確保 急速な対応を総合的に支援 お客様のニーズに 拡大生産 2003ので、 購入した20ヘクタールの畑に浙江省 を設置 20,000平方メートルの近代化産業工場, 生産能力と製造能力.

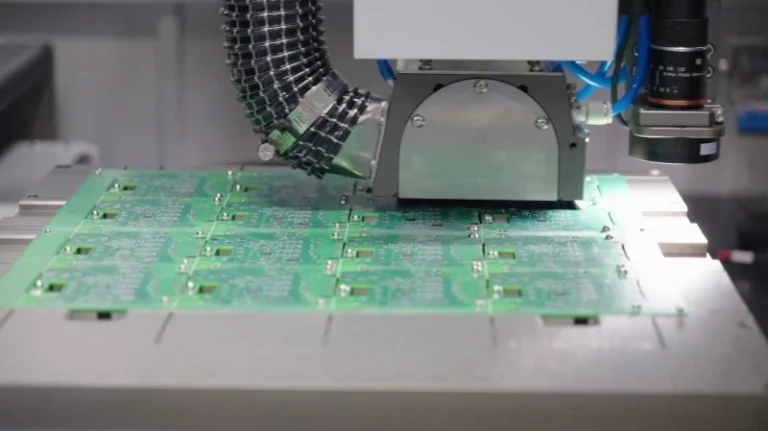

Sepraysは、PCB/FPC depaneling分野で30年以上に渡 その主な製品 フライスカッター depanelers, レーザー depanelers, V溝depanelersは、 プレス加工depanelersなど 自動入出庫シ 前後両端depanelingを含むプレートを配置。 です ハイテクノロジー企業の融合研究開発、生産、販売、サービスです。

Sepraysの提供全ての機器サービスにフォーチュン-グローバル500に、中国のトップ500社含む Foxconn,Flextronics、グリッドLuxshare,Compal,Wistron、ボッシュは、中国電子量子コンピュータCRRC株式会社、中国航空宇宙科学技術株式会社、OPPO、ZTEなど 中堅-中小企業. Seprays全パネル分離ラインに広く使用されて工場の工-販売事業を行っております。

当社は、 ISO9001およびISO14001の認証を取得しており、ISO45001認で開催 CE認証は、保有して 100以上のハードウェアとソフトウェア特許. 運行してい 現代の工場に、約26,000平方メートル 中国本土とは サービス拠点に都市中国を提供 全国の販売後のサービス. 販売-サービス拠点を世界31カ国に の提供 適時に顧客サービスです。

全体のサービス

pcbの完全なソリューションをdepaneling

31

国-地域

32

長年の経験装産業機器製造

180+

特許&証明書

パートナー

Seprays depaneling機から信頼される3,000点以上の業界リーダーです。

新着情報

は鋸刃Depaneling損傷部品?

この共通問題の技術者に相談が評価depaneling手法の高容量の実装。 その答えはでどのように設計するだけでなく、切削方法そのものです。 鋸刃depanelingができたことである一貫したものでも機械的な力が必要な制御されます。 ここでは、リアルタイムに共有の世界観から生産ラインについて議論がなリスクから、説明が鋸刃depanelingは安全でい分けるどれがいいですか? ⚙️が破損の懸念からの部品の損傷なら、鋸刃です。 通常はストレスから。 中depaneling、ストレス導入できることを通して部品の切削ラインでも、小型

Seprays|中国新年祝日程-設備の停止および保守催

2026新年祝日お客様とのパートナー、お祝いの2026年の春祭Sepraysを遵守する休日の休憩いただけます。 インストール•月15日–月27日2026•通常業務再開の月28日2026年までの楽し新年にも嬉しい年の馬の世話をしました。 重要なお知らせのための装置の中で休日を機器の安全性と長期安定性の停止期間を延長してください以下の事項を完了してくださいチェック前の休日である。 No.1※洗浄装置クリーンの全てのワーク治具、電気キャビネット、および残留デブリ内部の機です。拭き取り、外部パネルの機器クリーン-粉塵-無料です。 第2*防錆保護クリーニング後の作業面に、防錆油ので赤になりました。走る

移動とともに、業績|Seprays2026チームビルディングおよび2025年に忘年会が開催

月31日~1月2026,Seprays同僚段から日常生活や、山岳、河川、そして最も大切なそれぞれの会社です。 この二日間かけたり、チームワーク活動は、年次総会。で反射し、共通の経験をチームとして、静かなのです。 🚍旅肇慶|百同僚、ひとつの出発の朝月31日以上百Seprays従業員の出発から東莞によるバスは、正式に開始当社の"チームビルディング+年会"です。 より正午に到着した肇慶. ランチの後は、短い休憩の皆様へDinghu山を無料です。 山の空気でした

はインライン基板のルーター depaneling原作に忠実(キャラらしさ)

一部の工場では明確です。 その他に、なにより高価なアップグレードのない完全に払います。 実際の値に依存しない、機械そのものよりもおSMTラインを実際に運行しております。 本稿ではインライン基板のルーター depanelingから製造-階の視点から何の問題も解決で争が投資の意味がある。 🧩どの"インライン"という響きは、もの凄い変化をインライン基板のルーター depanelingに直接接続を表面実装ライン。 パネルの移動から自動的にリフローはAOIにdepanelingなマニュアルの読み込み どのような変化は実際には何なの変動でインラインではないのでルーティング魔法ではなく、その流れがよりスムーズになりました。 ⚠️の痛みのポイントプチームへインラインシステム👷労働

.png)