News

Multi-Blade PCB Depaneling Machine: High-Speed and Low-Stress Cutting

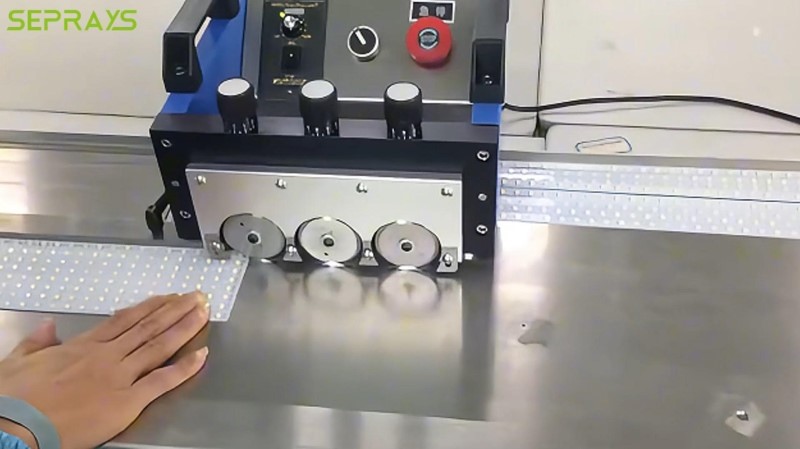

Multi-blade PCB depaneling machines are transforming how electronics manufacturers approach PCB separation.With rising production demands, low-stress and high-speed cutting is no longer optional — it’s essential. The right depaneling solution boosts yield, reduces damage, and accelerates throughput. ⚙️ Why Traditional Methods Are Falling Behind Manual depaneling or single-blade machines often slow production and increase risk.Common challenges include: These issues reduce yield, increase rework, and hurt overall efficiency.A multi-blade approach changes the game, offering faster, cleaner, and more reliable results. 🚀 How Multi-Blade PCB Depaneling Machines Work Unlike single-blade systems, multi-blade machines use several cutting heads simultaneously.This enables: By distributing the load across several blades, vibration is minimized, and components remain safe.Production speed increases without compromising precision. 🎯 High-Speed Cutting for Modern Demands Modern PCB lines require both speed and accuracy.Multi-blade depanelers achieve this through: Faster cycles mean higher throughput, while maintaining low stress prevents board damage. 🧹 Clean and Dust-Free Operation Debris is a hidden enemy in PCB production.Dust can contaminate components, reduce spindle life, and degrade cutting accuracy. Multi-blade systems often integrate: This keeps both the machine and PCB clean, extending service life and ensuring consistent quality. 🔧 Versatility and Adaptability Not all PCBs are the same. Some boards

How to Achieve Faster, Cleaner, and More Precise PCB Depaneling?

The PCB depaneling process plays a crucial role in modern electronics manufacturing. Every second saved, every micron of precision achieved, and every piece of dust eliminated adds up to a stronger, more reliable product line. In today’s competitive market, achieving faster, cleaner, and more precise PCB depaneling is no longer optional — it’s essential. That’s where advanced automation systems like the SEPRAYS GAM 330AT In-Line Automatic PCB Router Machine redefine what’s possible. ⚙️ Why Traditional Depaneling Methods Fall Behind Manual cutting or outdated semi-automatic systems often introduce vibration, dust, and human error.Over time, these issues lead to component stress, poor edge quality, and inconsistent yield. In contrast, smart inline depaneling solutions focus on stability, precision, and efficiency.They combine advanced motion control, real-time vision alignment, and fully automated handling — eliminating the weak links of manual work. 🎯 CCD Vision Alignment: Precision at Every Cut One of the biggest challenges in PCB depaneling is maintaining cutting accuracy as production speed increases. The SEPRAYS GAM 330AT solves this with CCD vision alignment technology.This system scans fiducial marks in real time and adjusts the cutting path automatically. The result? Every board is cut with pinpoint precision, regardless of slight shifts in position.Whether you’re

A Century of Evolution in PCB Depaneling Technology: The Industrial Transition from Manual Depaneling to Intelligent Laser Cutting

The evolution of PCB depaneling technology is, in essence, a reflection of the electronics manufacturing industry’s relentless pursuit of miniaturization, speed, and precision.This article explores the development of depaneling machines through three dimensions — technical principles, industrial transformation, and representative equipment — tracing their journey from manual processes to the era of intelligent laser depaneling under Industry 4.0. 🛠️ I. The Manual Era (Before 1950): The Dilemma of Efficiency and Yield 🔹 Technical Characteristics In the early days of PCB manufacturing, circuit boards were separated by hand.Operators used scissors or knives to break panels along pre-cut grooves — a “primitive depaneling” approach that suffered from two major flaws: 🔹 Industrial Context At this stage, PCB manufacturing had not yet formed a complete industrial chain. Depaneling was merely an auxiliary step — equipment automation and process optimization were still far from realization. ⚙️ II. The Mechanical Revolution (1950–1990): The Battle of Four Generations With the rapid rise of consumer electronics, depaneling machines entered a golden age of technological innovation, giving rise to four major mechanical approaches. 🟢 1. Punch Depaneling Machines: The Price of “Brute Force” ⚡ Principle: Hydraulic presses applied several tons of pressure, using custom molds to stamp and

Struggling with Slow PCB Cutting? Meet the SEPRAYS GAM336AD Solution

The SEPRAYS GAM336AD is redefining how manufacturers handle PCB depaneling.If your production line struggles with speed, precision, or labor costs, this automatic PCB router offers the perfect upgrade — clean, fast, and fully automated. In the age of high-efficiency manufacturing, staying slow isn’t an option. Let’s explore how this machine turns cutting challenges into smooth, seamless performance. ⚙️ The Challenge: Slow PCB Cutting Hurts Productivity Every second counts in PCB manufacturing.Manual or outdated depaneling systems not only slow down throughput but also risk damaging delicate boards. Vibration, human error, and inconsistent cutting lead to stress cracks and costly rework.The result? Lower yield, higher expenses, and reduced production flexibility. Manufacturers need a smarter solution — one that keeps up with modern demands. 🚀 The SEPRAYS GAM336AD Advantage The SEPRAYS GAM336AD combines automation, accuracy, and intelligent control into one powerful system. Key features include:✔ CCD vision for precision✔ High-speed spindle & auto tool-change✔ Dual worktables for nonstop production✔ Automatic sorting & tray loading — zero manual errors✔ Clean, efficient, and cost-saving This isn’t just a depaneling machine — it’s a complete productivity solution. 🎯 CCD Vision for Precision Alignment Every PCB design demands accuracy down to microns.That’s why the SEPRAYS GAM336AD comes

Revolutionize Your PCB Production | SEPRAYS GAM 380AT Automatic PCB Depaneling Machine

The SEPRAYS GAM 380AT Automatic PCB Depaneling Machine is changing how manufacturers think about precision, flexibility, and speed.In a world where every second counts, this intelligent depaneling system eliminates jigs, reduces stress, and keeps your production line running smoothly — from prototype to mass manufacturing. ⚙️ The Challenge in Modern PCB Production As electronics evolve, PCBs are getting thinner, denser, and more complex.Traditional depaneling systems struggle to keep up, causing vibration, dust, and misalignment. These small issues lead to big losses — damaged boards, downtime, and rework costs. What manufacturers need today is a smarter solution: precise, clean, and fully automated. 🚀 Meet the SEPRAYS GAM 380AT The SEPRAYS GAM 380AT Automatic PCB Depaneling Machine redefines efficiency through advanced engineering and user-focused design. Key advantages include:✅ Fixture-free precision cutting — no jigs, no limits✅ CCD vision alignment for perfect positioning✅ Flexible 0–180° unloading for seamless integration✅ Low-stress, low-dust cutting with high-speed efficiency✅ Clean, reliable, and automation-ready for modern production lines This is not just another depaneling tool — it’s a complete productivity upgrade. 🧠 Fixture-Free Precision Cutting Forget custom jigs and long setup times.With the SEPRAYS GAM 380AT Automatic PCB Depaneling Machine, fixture-free cutting gives you total flexibility. You can

Are Dust, Stress, and Inefficiency Slowing Down Your PCB Production? Meet the SEPRAYS GAM320A Offline Depaneling Machine with Upper Vacuuming

The SEPRAYS GAM320A Offline Depaneling Machine with Upper Vacuuming is designed to eliminate the hidden obstacles that slow down PCB manufacturing — dust buildup, cutting stress, and inconsistent precision.If your production line faces these common issues, it’s time to switch to a smarter, cleaner, and more accurate depaneling solution. ⚙️ The Hidden Enemies of PCB Production In high-volume PCB assembly, dust, stress, and inefficiency silently affect your bottom line.Manual or low-grade cutting systems often cause: These problems lead to costly rework, reduced yields, and lower production stability. 🚀 Introducing the SEPRAYS GAM320A Offline Depaneling Machine The SEPRAYS GAM320A redefines precision depaneling with a combination of speed, accuracy, and cleanliness. Its key features include:✔ Ultra-precise, low-stress PCB cutting✔ Integrated upper vacuuming for a dust-free workspace✔ CCD vision alignment ensures every cut is accurate✔ Flexible fixture adapts to multiple PCB designs Whether you’re handling fragile FPCs, aluminum boards, or dense PCBs, the GAM320A delivers stable, repeatable performance. 🌪️ Clean Cutting with Upper Vacuuming Dust is more than just a mess — it’s a production hazard.The GAM320A’s upper vacuuming system efficiently removes cutting debris as it forms, keeping the surface clean and preventing particles from contaminating boards or optical components. This not only

.png)