Specifications

| Model | ZM500 |

|---|---|

| Inspection | Aperture area, position, offset, size, foreign matter, burr, blocked hole, missing holes, tension |

| Measure time | 3.5min( 130*100mm, data:25122 holes) |

| Measurement accuracy of the opening area | Gage R&R<5.0% (Actual measurement is GR&R<1-2% or less) |

| Aperture measurement accuracy | ±10μm |

| Accuracy of the motion system | Repeatability ±4μm servo system (resolution: 0.5μm) |

| Tension detection | ±0.1N.cm, tension range 0-50N.cm |

| Offline programming | Possible |

| Data traceability | Automatically save inspection data saving |

| Resolution | Default 6.6μm, can be customized |

| FOV | 25*18mm (optional) |

| Motor | Linear motor |

| Platform | Granite table |

| Scan range | 550*550mm |

| Frame size | 736*736mm |

| Reports generation | Automatically generate inspection reports |

| Gas supply | 0.4-0.6MPa |

| Power requirement | 220V 50/60Hz 2000W |

| Dimension(W*D*H) | 1327*1266*1500mm |

| Weight | 1000kg |

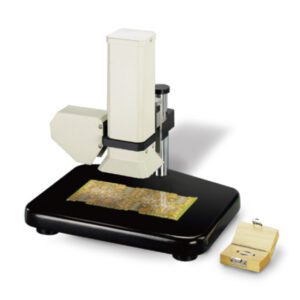

Product Introduction

Automatically detect area, position, foreign matter, holes, and tension.

High detection accuracy and large detection range.

Import GERBER data, a modular data structure, and check the results immediately within 2-3 minutes.

By measuring the size and position of the steel mesh opening, setting the error range, and comparing it with the reference value to see if it is qualified.

Simple and fast operation

Detection Items:

Detection of hole defects such as hole deviation, hole accuracy, shape, multiple holes, few holes, area error, edge burrs, etc.

Application Cases

The ZM500 stencil inspection system offers automatic, high-accuracy inspection of critical stencil parameters, including area, position, foreign matter, hole completeness, and tension. Designed for large inspection areas, this advanced system imports GERBER data and utilizes a modular data structure to deliver reliable results within 2-3 minutes, significantly improving production throughput.

By precisely measuring stencil opening size, position, and other key parameters, the ZM500 stencil inspection identifies defects such as hole deviation, accuracy issues, shape irregularities, extra or missing holes, area errors, and edge burrs. The system compares measured data with reference values to ensure product qualification, guaranteeing stencil quality and optimizing solder printing results.

✅ Fast, accurate, and comprehensive stencil inspection

✅ Supports smart manufacturing integration

.png)

评价

目前还没有评价