A Multi-Blade PCB Depaneling Machine is increasingly seen as a smart solution to common production bottlenecks in modern electronics manufacturing. Traditional single-blade or manual depaneling methods often struggle with speed, precision, and consistency — especially as PCB designs become more complex and miniaturized.

In this article, we’ll share real-world insights into how multi-blade systems enhance efficiency, reduce costs, and optimize workflow balance without compromising quality.

🔍 The Pain Point: When Efficiency Hits a Wall

Manufacturers face a familiar challenge: throughput limits. Even with skilled operators, manual or single-blade depaneling cannot always keep pace with automated SMT lines. Common issues include:

- Frequent downtime during board changeovers.

- Operator fatigue and inconsistent cut quality.

- Edge stress and micro-cracks, particularly on thin PCBs.

- High labor costs due to manual handling.

These issues not only affect yield rates but also slow down delivery schedules — creating a domino effect throughout the entire production chain.

🧩 The Multi-Blade Advantage: Parallel Cutting for Maximum Output

A Multi-Blade PCB Depaneling Machine introduces a different philosophy — one of parallelism. Instead of cutting one PCB at a time, it uses multiple circular blades that work simultaneously.

Key benefits include:

- High-speed depaneling for multiple boards per pass.

- Consistent precision through mechanical alignment and servo control.

- Low-stress cutting, preserving solder joints and sensitive components.

- Reduced operator involvement, enabling semi- or full automation.

This setup allows factories to achieve up to 3–5 times higher throughput compared to manual cutting, without the need to expand manpower.

💰 Cost Analysis: Efficiency That Pays Off

Let’s talk numbers. While the initial cost of a multi-blade machine may seem higher than a manual tool or a single-blade system, the ROI (Return on Investment) is rapid.

Typical outcomes reported by manufacturers:

- Labor reduction: Up to 70% less manual handling.

- Scrap reduction: Cut defects drop significantly.

- Cycle time improvement: Production speed increased by 200–400%.

- Payback period: Within 6–12 months for medium to large factories.

In today’s electronics market, where every second and every PCB counts, this efficiency becomes a strategic advantage rather than a simple cost-saving measure.

🧠 Case Example: Upgrading to a Multi-Blade Solution

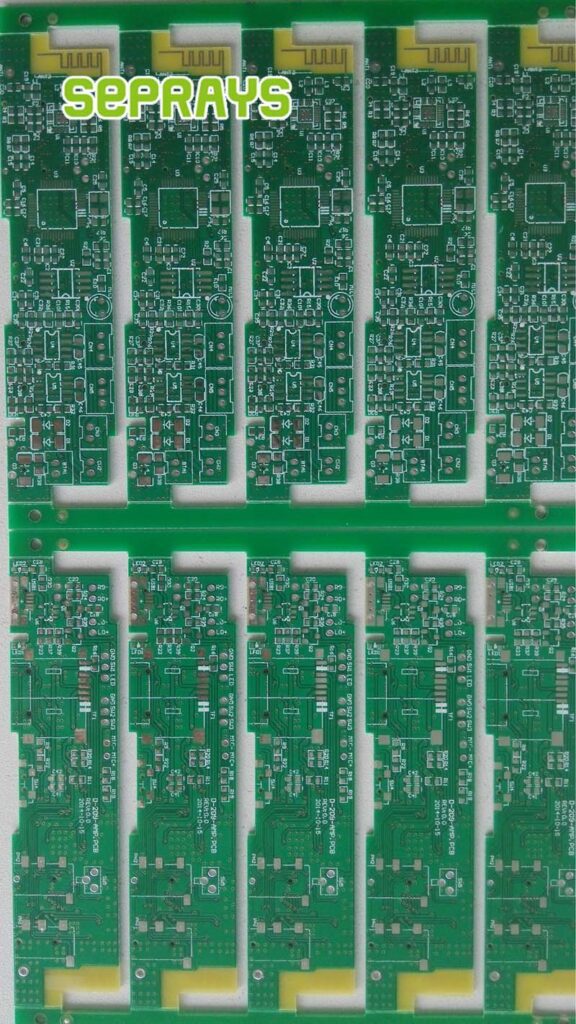

A Southeast Asian EMS company recently upgraded from a manual cutting process to a Seprays multi-blade depaneling machine.

Before:

- 3 operators per line

- 200 panels/hour

- Frequent rework due to edge cracks

After:

- 1 operator per line

- 600 panels/hour

- Consistent edge quality with <1% rework

This transformation allowed the factory to meet new customer deadlines and reduce overtime costs, ultimately improving both profit margin and team morale.

💬 Discussion: When Is a Multi-Blade System the Right Fit?

Not every production environment requires a multi-blade setup. For low-volume or prototype runs, a router or laser depaneler may still be more suitable. However, for mass production lines running thousands of similar PCBs daily, multi-blade depaneling becomes the most practical and economical option.

Questions to consider before adoption:

- What is your current depaneling throughput target?

- How consistent are your PCB designs?

- Are your labor costs increasing faster than your output?

Evaluating these metrics helps determine whether upgrading to multi-blade technology will yield long-term benefits.

🌍 Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

We combine advanced engineering with reliable service support, helping manufacturers achieve higher yields and smoother production.

📩 For more information, please contact us:

📱 WhatsApp: +86 189 2926 6433

📧 E-mail: sales@seprays.com

.png)