This question comes up whenever PCBA reliability, fine-pitch components, or thin substrates are involved. The short, experience-based answer is: laser depaneling introduces the lowest mechanical stress, but it is not always the default choice. Below is a clear comparison to help engineers make a practical decision.

🧠 Why Depaneling Stress Matters More Than You Think

Mechanical stress during depaneling is a hidden risk. It may not show up during visual inspection, but it often leads to:

- Micro-cracks in solder joints

- Latent failures in ceramic capacitors (MLCCs)

- Reduced long-term reliability in automotive and industrial electronics

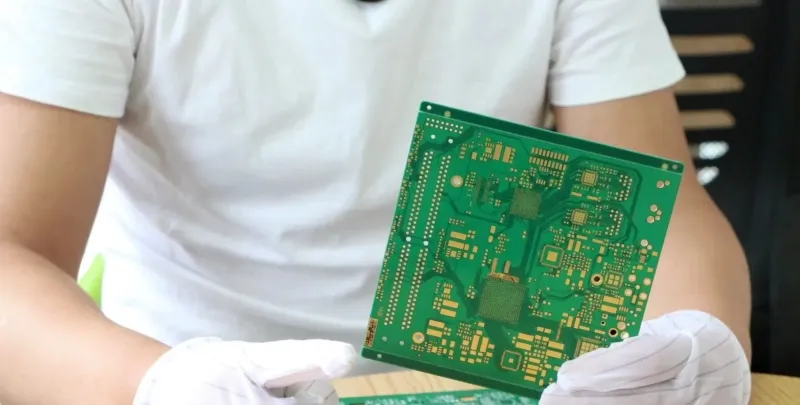

As component density increases and boards become thinner, depaneling stress becomes a design constraint, not a secondary process issue.

⚙️ Common PCB Depaneling Methods at a Glance

In practice, manufacturers mainly choose between four methods:

- V-cut (pizza cutter or blade separation)

- Saw blade depaneling

- Router (milling) depaneling

- Laser depaneling

Each method removes material differently—and that directly affects stress levels.

📊 Stress Comparison by Depaneling Method

Below is a simplified comparison based on field experience and production feedback.

| Method | Mechanical Stress | Edge Quality | Design Flexibility | Hidden Risk |

|---|---|---|---|---|

| V-cut | High | Medium | Low | Board bending |

| Saw blade | Medium | Medium | Medium | Vibration |

| Routing | Low–Medium | Good | Good | Tool pressure |

| Laser | Near zero | Excellent | Excellent | Minimal |

Key takeaway: Laser depaneling consistently produces the lowest stress because it is a non-contact process.

🔍 Why Laser Depaneling Causes the Least Stress

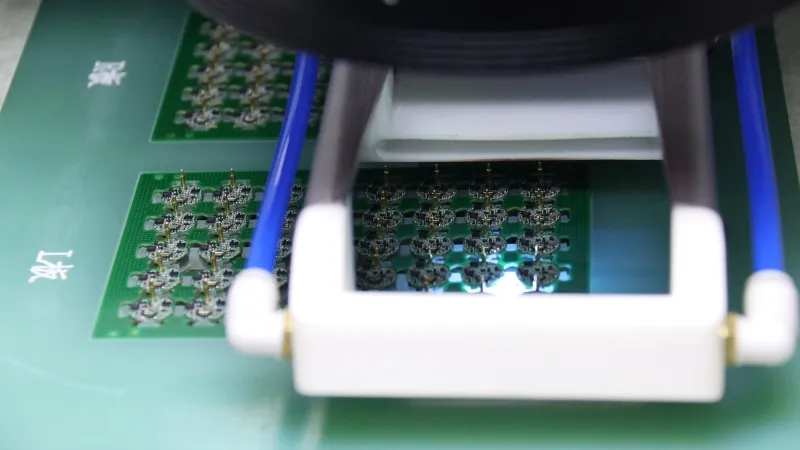

Unlike mechanical methods, laser depaneling does not rely on physical force. There is:

- No blade pressure

- No panel bending

- No vibration transferred to components

The cut is created by focused energy, which eliminates the root cause of mechanical stress. This makes laser depaneling especially suitable for rigid-flex boards, thin FR-4, and edge-mounted components.

💸 Cost Perspective – Stress vs. Total Cost

Laser systems are often viewed as expensive. However, stress-related failures are also costly:

- Rework and scrap from cracked MLCCs

- Field returns due to latent defects

- Over-designed keep-out zones waste PCB area

When these factors are included, laser depaneling can reduce overall manufacturing cost, especially for high-reliability products.

🧪 Case Insight from the Production Floor

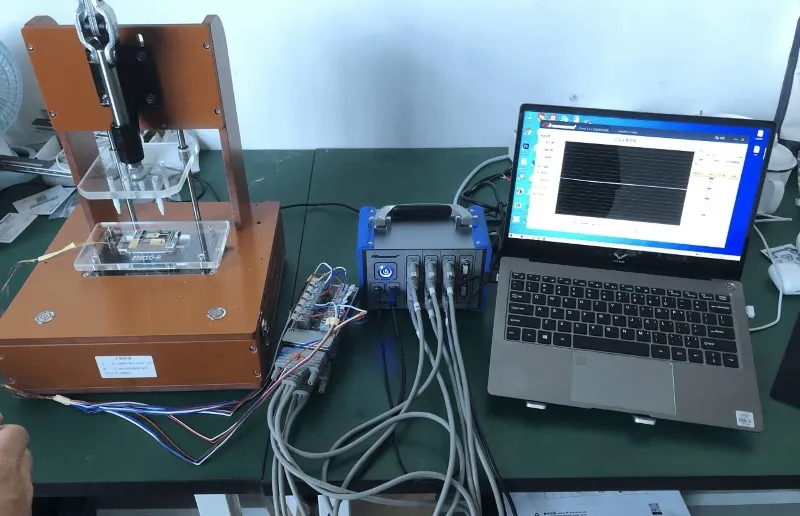

A manufacturer producing industrial control boards experienced intermittent failures after functional testing. Routing parameters were optimized, yet stress issues remained.

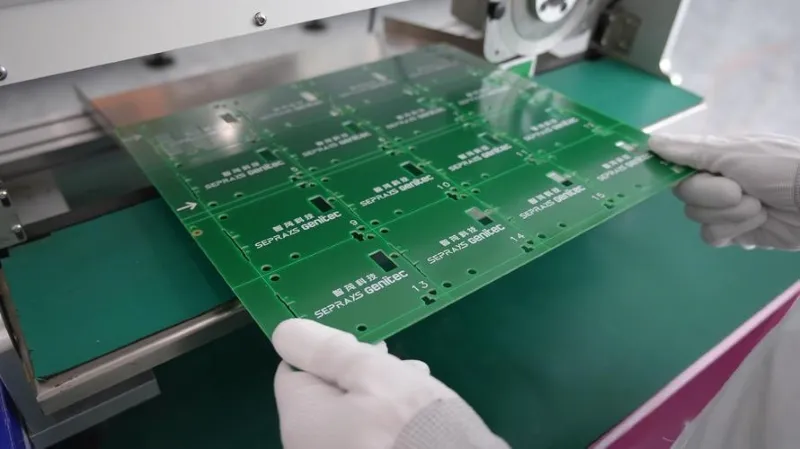

By introducing a Seprays laser depaneling solution for stress-sensitive boards, they achieved:

- Stable yields with no solder joint damage

- Cleaner edges near dense connectors

- Better material utilization due to narrower cut paths

Routing was still used for standard boards—but laser depaneling solved the critical reliability issue.

🛠️ Choosing the Right Solution in Real Projects

Laser depaneling is not a replacement for every scenario. A practical strategy is:

- Use V-cut or routing for thick, low-risk panels

- Use laser depaneling where stress, density, or flexibility matters

Asking “Which PCB depaneling method causes the least stress?” usually means the product is already pushing mechanical limits—and that is where laser technology fits best.

⚡ Seprays Laser Depaneling Advantages

Seprays laser systems are designed for stress-critical applications:

- Repeat precision (<2 μm)

- No mechanical stress or vibration

- Ultra-fine kerf (<25 μm), improving material utilization

- Free-form cutting without tool constraints

- No consumables such as blades or molds

- Clean, residue-free cuts

- Fast and automation-ready

These benefits directly address the limitations seen in mechanical depaneling.

⭐ Why Choose Seprays Group?

Seprays Group focuses on depaneling as a process, not just equipment. We help manufacturers balance stress control, cost, and throughput based on real production needs.

If you are evaluating low-stress depaneling solutions for your PCB or PCBA, contact us for a technical discussion or sample evaluation.

WhatsApp: +8618929266433

E-mail: sales@seprays.com

.png)