⚙ A milling cutter depaneling machine is one of the most versatile solutions for PCB separation. It is designed to cut a wide range of panel types while maintaining precision, low stress, and smooth edges. Unlike manual breaking or V-cut only methods, milling offers flexibility for complex board designs. But what types of panels are most suitable for milling? Let’s explore.

✂️ Standard FR4 PCBs

The most common material used in printed circuit boards is FR4, a fiberglass-reinforced epoxy laminate.

Milling cutter depaneling machines handle FR4 with ease, delivering clean edges without damaging internal layers. They are especially useful when PCBs have irregular outlines or dense component placement near the edge.

🧩 Complex and Irregular Panel Designs

Not all PCBs are simple rectangles. Many industries use boards with curved, angled, or irregular shapes.

Milling machines are ideal for these applications because they can follow programmed paths with high accuracy. This makes them suitable for medical devices, automotive modules, and consumer electronics where design flexibility is key.

🛡 Panels with Sensitive Components

Boards with delicate chips, connectors, or sensors near the edges are prone to stress damage during manual or V-groove separation.

A milling cutter depaneling machine applies precise cutting force, reducing mechanical stress. This makes it the right choice for high-density boards where protecting sensitive components is critical.

💡 Multi-Layer PCBs

Advanced electronics often rely on multi-layer boards to handle higher performance and complex circuitry. These panels are thicker and require precise separation methods.

Milling ensures smooth edges and prevents layer delamination. This accuracy is crucial in industries like telecom, aerospace, and automotive electronics.

🌍 Flexible and Mixed-Material Panels

Some applications use hybrid panels that combine rigid and flexible sections. Manual depaneling risks tearing or misalignment.

Milling machines can be programmed to cut rigid areas precisely while avoiding damage to flexible zones. This makes them ideal for wearables, foldable devices, and other innovative products.

🚀 High-Volume Production Panels

For manufacturers running large-scale production, milling depanelers provide consistent quality across thousands of boards. Automated dual-table or inline systems improve efficiency while keeping edge quality uniform.

This consistency is key in industries such as LED lighting and consumer electronics, where output volume is high.

🔮 The Advantages of Milling Over Other Methods

While V-cut and punching are effective for certain designs, milling offers unmatched flexibility.

- Handles irregular outlines.

- Maintains low stress on sensitive components.

- Works with different materials and thicknesses.

- Provides mirror-smooth edges.

This versatility makes it one of the most reliable depaneling solutions available today.

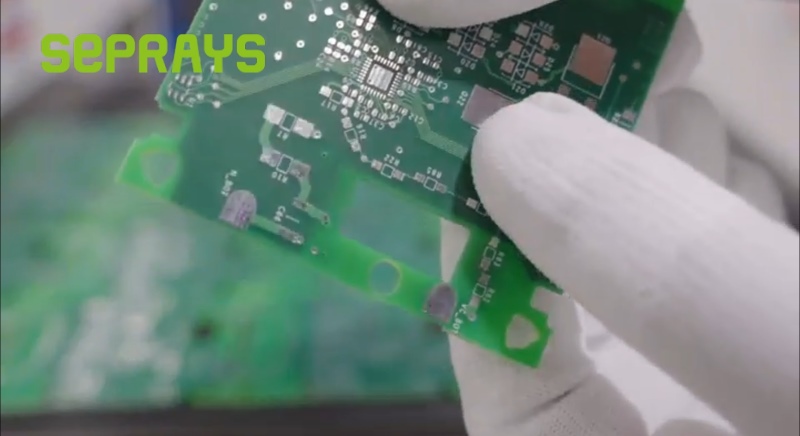

💡 Why Choose Seprays Group?

Since 1993, Seprays Group has been dedicated to PCB/FPC depaneling technology, providing a full range of solutions — milling cutter depanelers, laser depanelers, V-groove depanelers, punching depanelers, and automated handling systems. Our equipment is trusted by leading manufacturers, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, China Electronics, Quanta, CRRC, China Aerospace, OPPO, ZTE, and Bosch, serving factories across China and worldwide.

- Over 32 years of manufacturing experience.

- CE-certified equipment with patented dust control designs.

- Global service network in 31+ countries.

- ISO9001, ISO14001, and ISO45001 certified.

With proven reliability and global expertise, Seprays helps manufacturers achieve higher yields, better efficiency, and long-term product quality.

📧 If you need support, please contact us today.

WhatsApp: +86 189 2926 6433

E-mail: sales@seprays.com

.png)